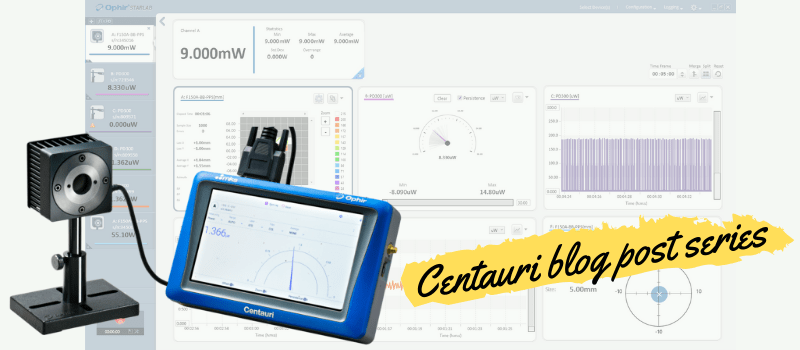

We at Ophir believe that our thermal sensors can be used for many years without the need of repairs when used with the proper laser optical setup. But often, when we receive sensors for calibration, we can tell that misuse is leading to early deterioration.

Through the years we were able to identify 3 main reasons that lead to out of tolerance conditions:

Surface contamination

Many times we find foreign substances on the surface of the sensor disc. Unfortunately, due to the different environments that sensors are used in, it is nearly impossible to conclude exactly what causes the contamination in each scenario. Welding environments are a common source of contamination. It is important to identify the source of the contaminant. Organic contaminants, for example, can get burned onto the surface by exposure to a laser beam. Prevention is much easier than repair; cleaning the sensor’s absorber surface (cleaning guidelines can be found in our website FAQ section), using accessories such as the Solenoid-Operated Protective Housing, and even just keeping the sensor in a proper container when it is not in use, can help avoid problems.

Overheating of the sensor body

Occurs when the disc is used continuously at a power level higher than it is rated for. Many Ophir sensors are rated at one specific power level for continuous laser power and a separate higher level for shorter periods of use. If your sensor has a name that ends with the letter C, it has different power levels it is capable of handling depending on if it is used with a heatsink or not.

2 types of damage that can occur from overheating are:

- Coating failure – the absorber will need to be replaced

- Grease contamination (for sensors using thermal grease) – usually, disassembling, re-greasing and cleaning the absorber by our technicians solves the problem.

Localized overheating of the coating

This is the number one cause of disc replacement with our sensors. Each coating type offered by Ophir has a specific power and energy damage threshold for localized power and energy density incident on the surface of the absorber. The specification sheet for each sensor will specify the general limit for power and energy damage.

You can learn more about the subject of preventing damage to your thermal laser sensor in this article.

Leave a Reply

Your email address will not be published. Required fields are marked *