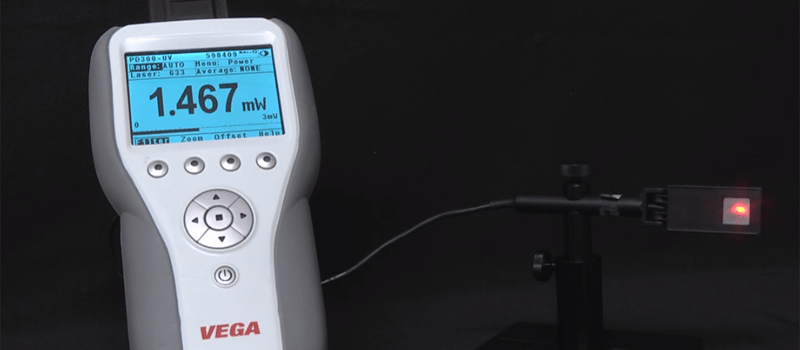

This blog is meant to help you navigate the tens of photodiode sensor models offered by Ophir for the measurement of optical power [Watts] and enable you to choose the one best suited sensors for your applications.

First a general word about photodiode power sensors in contrast to thermal sensors. Photodiodes are typically used for low power light sources (mW level) and are limited to certain wavelength ranges. The main advantage of photodiode sensors over thermal power sensors is their fast response time and their ability to measure very low powers without thermal noise.

The Ophir catalogue defines three categories of photodiode power sensors;

1) Standard photodiodes 2) Integrating spheres 3) Special photodiodes.

The Standard photodiode category contains all the sensors that can be used to measure the power of small diameter low divergence light sources with powers ranging from 300 fW to 3W and wavelengths ranging from 193 nm to 1800 nm. See below for specifics on how to find the right standard power sensor.

The Integrating sphere category contains all the sensors based on an integrating sphere principle (see integrating sphere article). These sensors are capable of making measurements that standard photodiode sensors cannot, such as; measuring highly divergent beams, measuring powers larger than 3W (up to 30W), measuring large diameter beams. Another advantage of integrating spheres is their ability to enable multiple measurements at once as will be explained in the relevant section below.

Lastly, special photodiodes are designed for specific applications in which the standard photodiodes and integrating spheres cannot be used. Applications such as sensors for microscope setups, barcode laser measurements, flat response photodiodes for wide band sources or multiple wavelength sources, eye responsivity and more.

It is important to note that there are also photodiode sensors used for the measurement of laser energy and irradiance, these will be dealt with in a different blogs.

Standard photodiode power sensors

As described above this category contains the workhorses of photodiode laser power measurements. If you need a sensor to measure a low divergence source (<15 degrees) with a power ranging from 300 fW to 3 W this is the place to look. The selection criteria are based on your application parameters as follows:

- Beam size

- Wavelengths

- Power range

- Power density

- Energy density (for pulsed lasers)

- Pulse width (for pulsed lasers)

- Rep-rate (for pulsed lasers)

- Size limitations (to choose between rectangular, round or thin profile sensors)

So, when you select a sensor you need to make sure that the specs of the sensor you choose cover all of your requirements. This can be easily done by using Ophir’s Sensor Finder application which will supply a list of sensors that will fit your requirements.

Integrating sphere power sensors

If your application has one of the following characteristics you should look to this category for the right sensor:

- Divergent beam (greater than 15 degrees and up to ±85 degrees divergence!)

- A need for high spatial and/or angular uniformity, i.e for a scanning beam (such as in LIDAR applications).

- Large diameter beam (up to 63. 5 mm)

- Powers higher than 3 W

- A need to measure other parameters simultaneously to power (pulse width, rep-rate, spectrum).

- Size limitations

All of the application parameters given in the previous section apply to integrating spheres as well and the Sensor Finder application can be used to eliminate spheres that do not fulfill those requirements. After an initial sensor finder search an additional selection step to refine the suggested spheres is required. In the second stage the right sphere should be selected based on the following parameters:

- Divergence of the light source:

The integrating sphere sensors are split into two families, those designed for Collimated beams and those designed for divergent beams, this is indicated by either ‘C’ for collimated (<15 degrees) or ‘D’ for divergent in the product name. Notice that different sphere designs support different divergence angles. - Additional measurement needs (accessories may be required when spectral measurements, pulse width or repetition rates need to be measured).

- Size limitations.

Once you have followed these steps you should get the P/N of the sphere you need with the P/N’s of the relevant accessories.

Special photodiodes

This category currently contains 4 types of sensors:

- Broadband sensors: These sensors are designed to have a flat response across a large wavelength range. This is useful in a number of applications such as; wideband light source measurements (such as LEDs), measurement of systems with multiple laser wavelengths that are incident simultaneously.

- Microscope slide sensor: This sensor was designed with a footprint of a microscope slide and its primary use it for the measurement of fluorescence excitation sources at the focal plane of a high N.A microscope objective (even with oil/water immersion). Since the responsivity of this sensor has very low angular dependence it can also be used to measure small divergent sources such as optical fiber outputs.

- CIE sensors: These sensors have a responsivity curve similar to that of the human eye and are used to measure light in units of [Lux], one of the applications of this type of sensor is for eye safety measurements.

- Scanning laser sensors: This sensor can measure the power of a moving beam which is incident on the sensor for only a short period of time (down to 13 µs). This is typically used in the measurement of bar code scanner lasers.

So to summarize, when you need a photodiode sensor to measure the power of a light source first see what category it falls under and then use Sensor Finder to get a list of sensors that can be used in your application, if needed refine the list of suggested sensors to find an integrating sphere that fits your needs. In some cases you may used one of the special photodiode sensors that are tailor made for your application.

Leave a Reply

Your email address will not be published. Required fields are marked *