|

Laser characteristic |

Which profiler fits |

Notes |

|

Wavelength Criteria |

|

|

|

Wavelengths of 250nm-1100nm |

Silicon detector camera and scanning slit based profilers. |

These are the most cost-effective profilers. They include CCD or CMOS cameras and silicon detector-equipped scanning aperture systems. |

|

UV Wavelengths of <190nm-250nm |

CCD and CMOS cameras are best but they can be damaged at these wavelengths. Conversion plates and imagers will be necessary for more than occasional use.Pyroelectric, imagers and scanning slit, systems can operate deep into the UV without risk of damage. |

|

|

Wavelengths from 1100nm-1700nm |

Up to 1300nm, regular silicon cameras will work. After that, either pyroelectric/InGaAs arrays or germanium/pyroelectric scanning slit systems are necessary. At lower resolution, Phosphor coated arrays are also available |

Pyroelectric and InGaAs are 5-10 times the price of silicon detectors. Scanning slit systems are lower in price. Phosphor coated arrays are the least expensive with resolution of ~50mm |

|

Wavelengths >1700nm |

Pyroelectricimagers and scanning slit systems, can operate into the far infrared. |

|

|

Beam Size Criteria |

|

|

|

Beam diameter of ≥ 1mm |

Silicon, InGaAs, Phosphor coated and Pyroelectric arrays are suitable. Scanning slit systems are available with apertures up to 25mm. |

Beam should cover about 10×10 pixels. Pyrocam pixels are 100mm. |

|

Beam diameter of ≥250µm |

Silicon and InGaAsarray pixels and scanning slit systems |

InGaAs pixels size is ~30mm. |

|

Beam diameter of ≥50µm |

Silicon cameras, with smaller pixel sizes and scanning slit systems |

The pixels on silicon arrays are down to ~4mm |

|

Beam diameter of 4µm – 50mm |

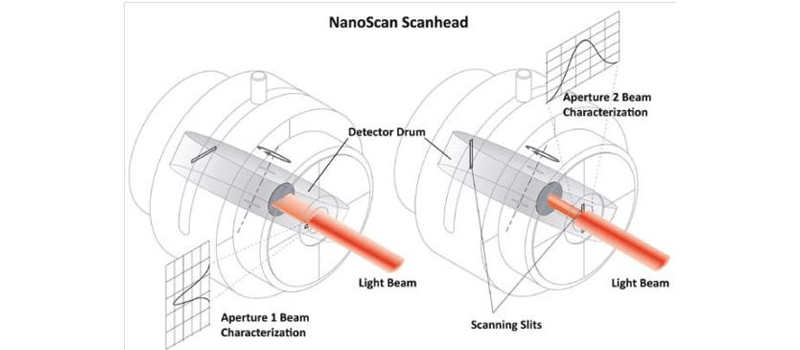

Scanning slit profilers only |

|

|

Powerand Energy Criteria* |

|

|

|

Powers>100mW up to ~300W |

Direct Measurement: Pyroelectric detector equipped scanning slit profiler

Using beam splitters/attenuators: array profilers

|

The amount of power being measured will affect whether or not attenuation or beam splitting is needed. It will also determine the detector type. Of course, as we’ve seen, CCD and CMOS cameras will always need attenuation. Scanning slit profilers can measure beams directly without attenuation.

|

|

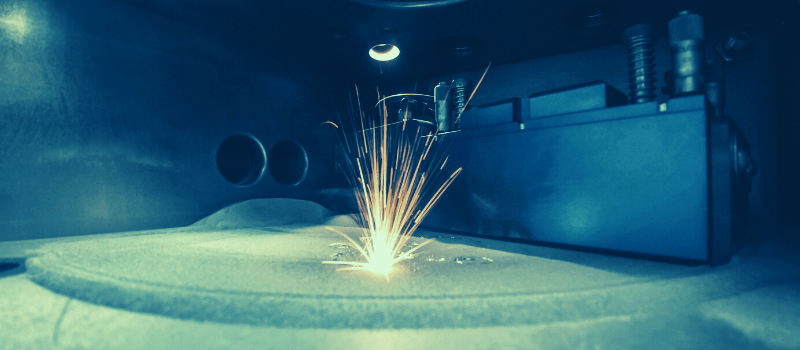

High power lasers >300W up to thousands of watts |

Spinning or scanned wire techniques or beam splitters with scanning slits |

|

|

Pulsed lasers at a repetition rate of less than 1Hz-2kHz |

Camera array profilers |

|

|

Continuous wave lasers or pulsed lasers with repetition rates above 2kHz |

Camera array profilers or Scanning slits |

This depends on the repetition rate, beam size, the length of the pulses, power levels and pulse energy thresholds. |

* All of the above technologies can be used at most power/energy levels but will require varying amounts of beam attenuation before exposing the detection system to the laser beam.

More Questions

How, where and for what purpose will your profiler be used?

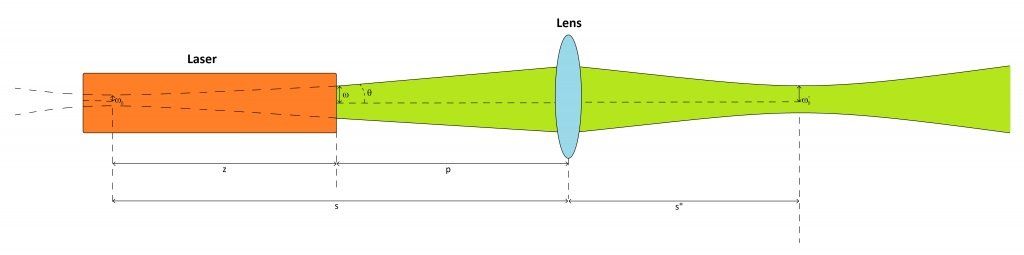

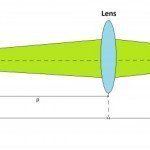

The scanning slit system does not need much or any attenuation which makes it easier to use, especially with continuous wave (CW) or high frequency pulsed lasers. It can measure focused and unfocused beams one after the other and it can also measure very small beams directly. This could make it the profiler of choice on a factory floor since it creates ease of use. It is also good for measuring a laser at various points along its propagation, like in the case of the M2, or focusing an optical system.

The camera array profilers are suited for both CW and pulsed lasers and reveal true beam profile structure (which is important for tuning lasers) since it shows a two dimensional view of the beam. The spatial resolution of a camera based system is best for performing more complex beam analysis such as TopHat, Gaussian Fit, Orientation, Ellipticity, etc.

Read the full article Beam Profiling: A Primer by Allen M. Cary, Photon Inc., San Jose CA

You might also like to read: Driving Blind: Why the Need for Industrial Laser Beam Profiling?

Share this:

Scanning slit low cost mbeam profiling 635nm- 1550nm simultaneous allignment application