You’re probably thinking, “Okay, I get it. Beam profiling is important. But saving lives? Come on.”

No, really, it can – and it has.

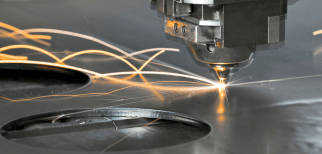

Let me tell you a story about how more than just money was saved when a biomedical parts manufacturer had the foresight to turn to Ophir-Spiricon for help analyzing their laser systems.

It all started when they were required by their customer to increase production, which led to the purchase of an additional laser system. After the installation and their qualification of this system, they noticed that the second laser was not performing nearly as well as their first laser. During their quality inspections, they discovered that the laser-welded parts it output were susceptible to cracking, implying the laser welding process wasn’t using the correct amount of heat. The company was especially baffled by this as the two lasers were identical models applying the exact same parameters. Because of their proactive approach to measuring their laser and controlling their laser parameters from those measurements, they were able to avoid providing faulty parts, which in the biomedical industry, could have meant a very expensive recall, or even worse the loss off life.

See how disaster was averted with these simple steps.

You might also like to read:

Measuring laser focus spot size in an industrial medical device application

Medical Laser Applications: Beam Measuring & Profiling

Leave a Reply

Your email address will not be published. Required fields are marked *