Short-Wave Infrared (SWIR) lasers operating at 1064 nm and 1550 nm are at the forefront of innovation in LiDAR, telecommunications, OCT, and laser materials processing. Precise beam characterization, especially M² and propagation analysis, at these wavelengths is critical to ensure optimal laser performance.

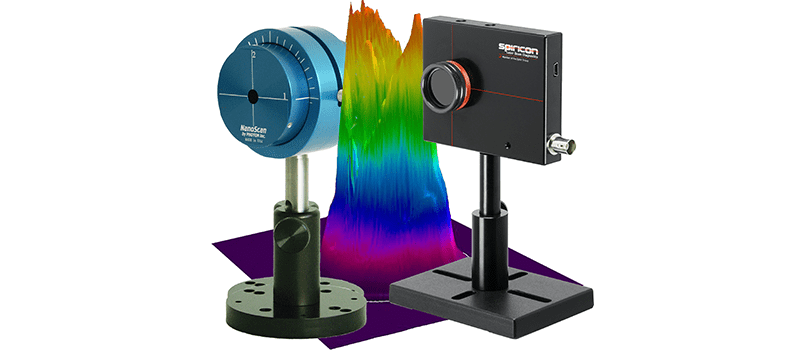

With the discontinuation of the XC130 camera, Ophir introduces the BeamSquared SP1203, a high-resolution, next-generation InGaAs camera purpose-built for accurate, ISO-compliant M² measurements in the 900–1700 nm spectral range.

Designed to Replace XC130 – And Go Beyond

The BeamSquared XC130 camera has reached end-of-life, creating an urgent need for a high-performance replacement. The SP1203, built on a high-resolution InGaAs. Focal Plane Array (FPA) sensor delivers significantly enhanced spatial detail and profiling capabilities, while maintaining the same spectral coverage and compatibility with existing BeamSquared systems.

Key Feature Comparison: SP1203 vs. XC130 Cameras

| Feature | SP1203 | XC130 |

| Sensor Type | InGaAs FPA | InGaAs CCD |

| Resolution | 640 × 512 | 320 × 256 |

| Pixel Pitch | 15 µm | 30 µm |

| Spectral Range | SWIR | SWIR |

| Min. Measurable Beam Size | 150 µm | 300 µm |

| Interface | GigE (via USB3 adapter) | USB 2.0 / 3.0 |

| Frame Rate | 60 fps | 100 fps |

Precision Validated

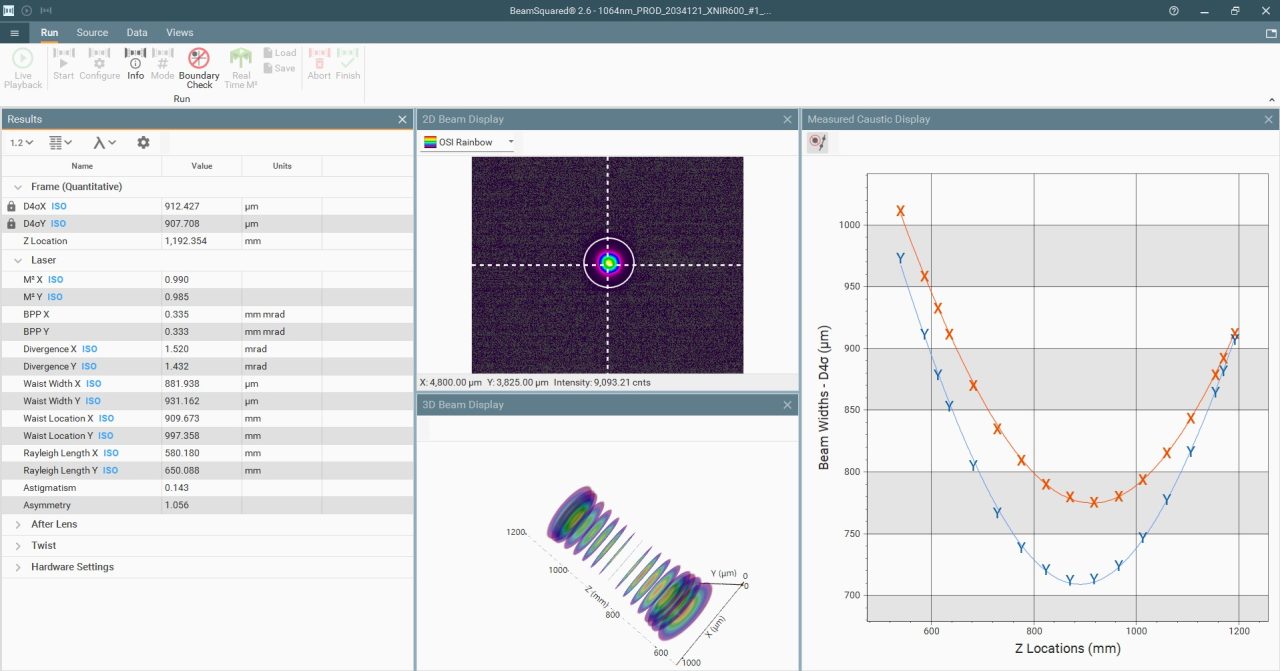

The SP1203 has been rigorously tested across various beam sizes and operating conditions. Key M² parameters, waist location, divergence, Rayleigh length, astigmatism, were measured using industry-standard procedures. Repeatability and accuracy were benchmarked against trusted reference systems.

Results:

- M² deviation: within ±5%

- Waist location accuracy: within ±10%

- Cross-system repeatability: ±5%

Plug-and-Play System Integration

The BeamSquared SP1203 system includes:

- Lens Kit for NIR and SWIR focal lengths

- Camera Kit with GigE-to-USB3 adapter and Ethernet cable

- BeamSquared Software, ISO-compliant and license-activated

Its modular design supports both lab setups and production-line deployments with minimal calibration overhead.

Why Choose the BeamSquared SP1203?

- A Technical Perspective

For engineers and system integrators working in the SWIR domain, precise and repeatable M² measurements are not optional, they are essential for validating system performance, ensuring optical alignment, and meeting regulatory and quality standards. The SP1203 delivers on every critical technical front.

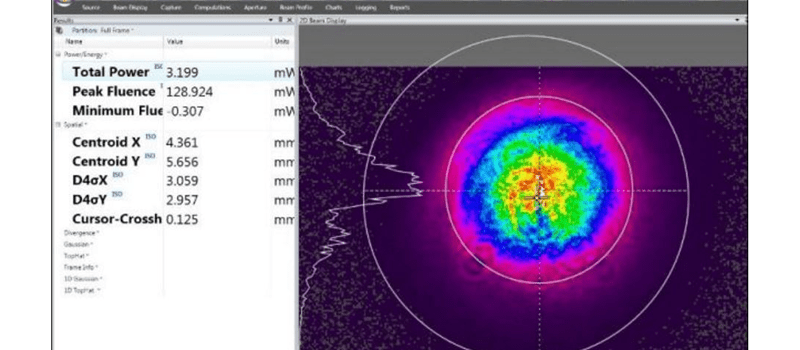

- Higher Spatial Resolution

The 640 × 512 InGaAs FPA sensor offers 4× the resolution of the legacy XC130, allowing for detailed profiling of complex mode structures and finer spatial features. Enables measurement of smaller beam diameters and tighter waists with higher confidence.

- Smaller Pixel Pitch = Finer Profiling

With a 15 µm pixel pitch, SP1203 supports smaller beam spot analysis, ideal for single-mode and fiber-coupled lasers where tight focusing is critical. Allows users to resolve features previously lost to under-sampling with coarser-pitch sensors.

- GigE Data Interface for High-Speed Laser Systems

The Gigabit Ethernet interface, paired with USB3 adapter, provides high-throughput, stable communication, crucial for MHz-pulsed sources where frame drop or temporal skew can corrupt M² calculations.

- Wide Spectral Sensitivity with InGaAs FPA

The sensor is specifically tuned for the SWIR band and performs consistently across a wide range of wavelengths.

FPA (Focal Plane Array) architecture ensures high uniformity, fast response, and low noise, essential for quantitative beam profiling.

- Consistent Measurement Accuracy Across Systems

Internal calibration routines and high signal-to-noise performance yield ±5% M² repeatability and ±10% waist location accuracy, even when testing across multiple devices or labs.

Complies with ISO 11146-1/2 for laser beam characterization standards.

- Minimal Measurement Artifacts

Compared to older CCD-based sensors, SP1203’s InGaAs FPA offers improved linearity and fewer blooming or charge-spill artifacts when measuring high-intensity or tightly focused beams.

Applications That Benefit

- Laser Manufacturing QA

- Fiber-optic Component Validation

- Optical Coherence Tomography (OCT)

- LiDAR and Sensing

The BeamSquared SP1203 combines high-resolution SWIR sensing, fully automated M² analysis, and robust system integration to deliver consistent, accurate beam quality measurements. It is engineered to meet the demands of modern laser systems, whether in fiber laser production, LiDAR validation, or telecom component testing, providing the precision and repeatability essential for today’s performance-driven applications.

Leave a Reply

Your email address will not be published. Required fields are marked *