There is a great quote attributed to W. Edwards Deming, who many consider the father of modern industrial manufacturing: “If you can’t describe what you are doing as a process, you don’t know what you’re doing.”

In welding and cutting, since lasers are very volatile, often your laser can feel like a stranger to you. You might know that you are using a CO2 laser of a certain power level but you can tell something is off kilter – you just can’t figure out what.

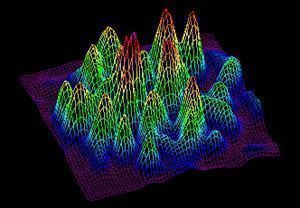

The most commonly used measurement tool for CO2 lasers is acrylic mode burns. Here is an example of results from this measuring method:

Figure 1: There are obvious differences between each burn but what exactly is changing is a matter of interpretation.

The main drawbacks of acrylic mode burns are:

1. Time exposure – It cannot detect changes happening over time (during start up or during processing).

2. Potentially toxic – It produces carcinogenic fumes and so proper ventilation is necessary.

3. Subjectivity and inaccuracy – It is highly dependent on poorly controllable factors and interpretation of results is highly subjective.

Looking at the results from the burn example above, many questions remain unanswered. How is the power dispersed? How is the beam changing over the course of those few seconds? What is the shape of the laser head?

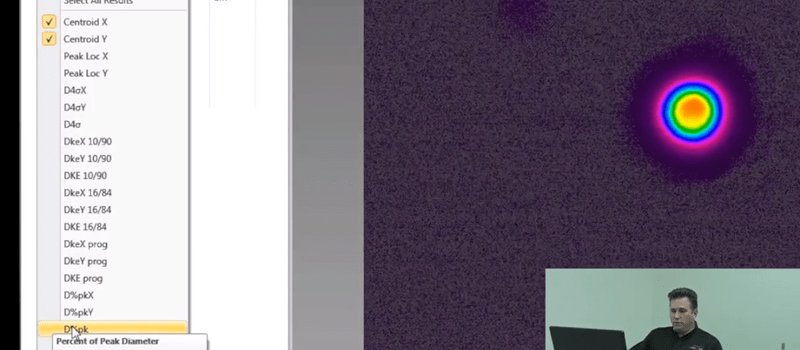

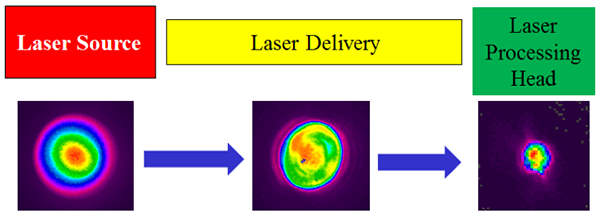

Now look at the two images below:

Figure 2: Beam Profiles taken only 500 ms apart of a 6 kW CO2 welding laser. The beam width changed by 10 percent, illustrating the transient effects not measurable with non-electronic methods.

The fact is that in laser processing, if one cannot measure the spatial profile of the laser, then one cannot fully understand what that laser is doing at the work surface. The above images show an example of a laser substantially changing within 500 milliseconds, something you cannot know without digital measuring methods.

ModeCheck®

Considering all the factors mentioned above, Ophir-Spiricon has developed a new beam profiler, ModeCheck®, to fit the needs of the industrial technician using a CO2 laser for welding or cutting.

In a nutshell, ModeCheck® is:

1. Low-cost

2. Easy to use

3. Takes 1-2 minutes set-up time

4. Doesn’t require special alignment

5. Can be used by people with no special skill level

6. Displays detailed and high quality beam images in real time

7. Displays 2D and 3D beam images in real time, along with important beam parameter calculations.

8. Has frame rates up to 100 per second

9. Is far safer than acrylic mode burns

10. Data that is reproducible and independent of the user.

Learn more about the new ModeCheck® here.

You might also like to read: Old Acrylic Blocks Are a Thing of the Past!! A Guest’s Perspective…

Please feel free to comment and add things you have on your list

Share this:

If it works, that would be great.