Many materials processing laser applications, for example cutting, drilling or marking, all involve a machine inside of which there is a laser and an opto-mechanical system which includes beam shaping and focusing optics, a beam delivery system, and perhaps a galvanometer scanner or other moving parts depending on the application. All these parts have to be aligned when the machine is built and have to maintain their alignment over the course of the machine’s operating life time.

Aligning all the parts of a laser system can be a tedious task, as alignment often requires a personal touch and a high level of hand-eye coordination to place each element in its exact location and angle for the system to function precisely. One of Ophir’s clients which manufactures a variety of laser machines for materials processing applications pointed out that only their most skilled technicians who have years of experience can easily assemble a laser system in a short period of time. This client was very interested to hear about Ophirs’ new Beam Track series and how helpful it is for assembling laser machines.

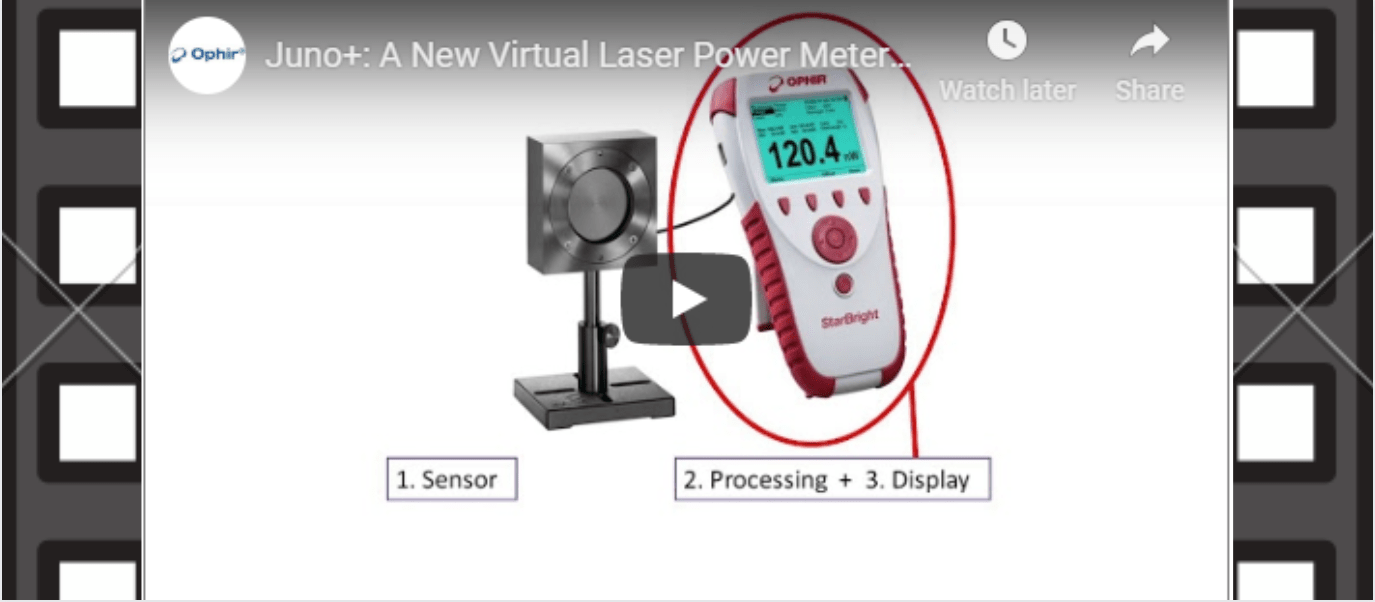

Ophirs new Beam Track laser power and energy sensor series can make laser system alignment a semi-automated process and thus a much easier task. In addition to laser power measurement, a beam track sensor can also indicate the exact location of a beam. Knowing a beam’s exact location makes it easy to know how to adjust the optics and elements so the beam is directed exactly to its intended location.

After a short demonstration of the Beam Tracks capability of indicating a beam’s location, our client expressed interest in an OEM beam track version that could be integrated into his laser systems. Over time one of the optical elements can slightly move or can get a little bit dirty, causing a shift of the beam from its intended target, which can cause poor performance of the machine. A Beam Track sensor integrated inside a laser system, that measures and tracks a beam’s location right before it is delivered to the work surface, can automatically notify the controller about any shifts in the beam’s location . This enables the operator to initiate preventive maintenance and avoid machine down time.

You might also like to read: The new Ophir BeamTrack sensor- You won’t believe how useful it is!

Share this:

Using optical measuring tools to calculate the exact centre of objects would be a way to accomplish this. It’s very important instruments like this are exact.

I really enjoy the blog.Much thanks again. Great.

Dear arsenal,

Thank you for your kind response.

We are happy to know you find our blog post relevant and efficient.

Feel free to keep sharing your thoughts with us in the future!