A typical concern when using a laser cutting machine is how to be sure the laser is optimized for the most efficient process. This means, is the laser power high enough? Is it focused down well enough? And is it focusing at the proper place (above, at, or below the material)? These parameters vary depending on the process, but one thing is sure: you’ll never know what the laser is doing until you measure it.

So the next question is: “How can I measure the width of the focused laser beam when its power density is hundreds of kilowatts per square centimeter?” And the typical answer would be: It’s impossible.

Things have changed, however, with the introduction of Spiricon’s new BeamWatch, which measures laser beam width and focal length of any laser beam without attenuation.

Spiricon’s BeamWatch

This probably seems too good to be true. The power density of a tightly focused industrial laser can be quite high. It took me only a few minutes online to find a laser that outputs 16 kW and can be focused down to 300 microns. At the maximum power and focus, this yields tens of megawatts per centimeter squared. This far exceeds the damage threshold, not only of a regular beam profiler itself, but of any attenuating accessory as well (filter, beam splitter, etc.).

But BeamWatch can take it without any attenuation.

How can this be true?

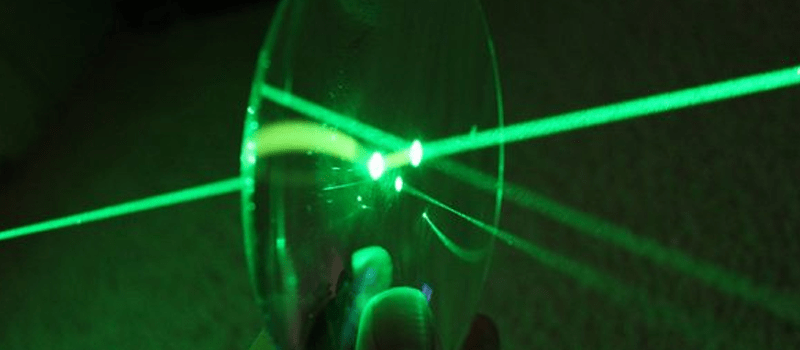

Because the laser beam is not in contact with anything.

There are many different approaches to profiling high power laser beams, but the method used in BeamWatch – although groundbreaking – could be called the simplest. If the concern is that a laser beam has so much power that it will burn whatever it hits, why not let it pass right through the beam profiler; if it doesn’t touch anything it can’t damage anything.

Okay, wise guy, but we still want to measure the laser…

Right, so that’s probably why no one thought of this before. It has always been taken for granted that some physical thing must collect (at least some of) the light from a laser in order to measure its parameters, such as beam width, position, profile, etc. However, this need not be the case.

One can actually get an accurate measure of the beam’s width and focal spot position by measuring its Rayleigh scatter, which means that the laser beam itself can pass right through the detector, touching nothing but the air inside it. As such, there is no upper limit to laser power.

BeamWatch has already been tested successfully on a 30 kW laser and Ophir-Spiricon will test it at 100 kW soon. Power density is not a problem either, so your laser can be measured exactly as it will be used, even at the focus spot.

For laser cutters everywhere, there’s now a quick way to measure your laser’s focal length and beam width at its waist. With quick results and no need to change your optical setup after measurements, you can spend more time cutting steel and less time looking under the hood of your laser cutting system.

You might also like to read:

Looks great!

May I have some technical info and a price quotation for the Ben Gurion University?

Best,

Avigdor zajdman

Thanks for your interest, Avigdor. I sent you a private email for further information.

Effy