Picture this.

Your boss has been bugging you about the low welding yields lately, and you can’t disagree. As the laser technician, you have to find out why the laser welders haven’t been working as well as they should. It’s not just that they are slower than advertised, but they’re producing imperfect welds.

You know that laser welding is supposed to be more efficient than traditional methods, not the opposite. So why is your laser welder not performing?

As an experienced laser technician, you realize that you can’t make any conclusions without first measuring the laser.

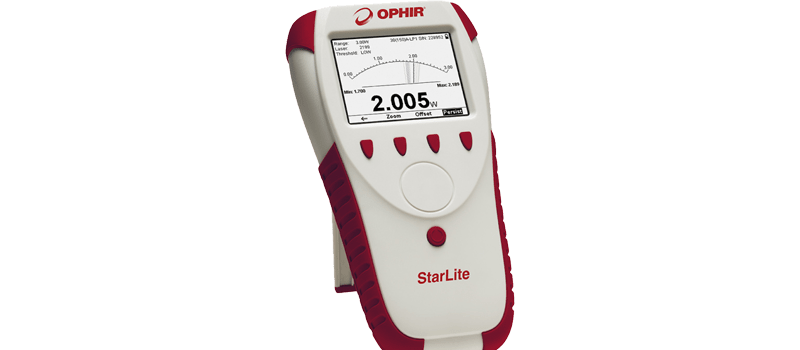

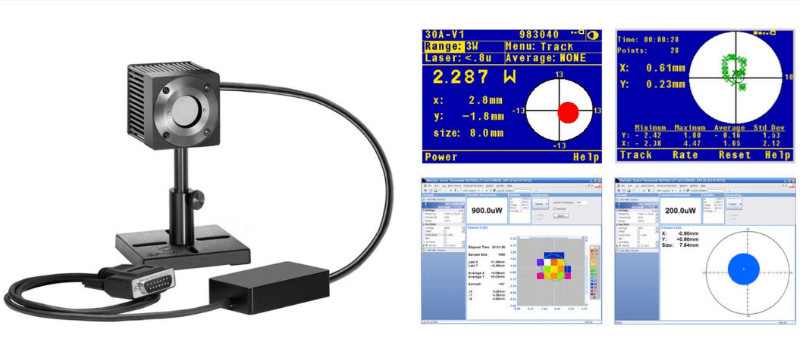

So you start with a power measurement, since power density is a main factor of laser welding performance.

But already you run into a problem. At focus, the beam could be more than 1 MW/cm2, which will certainly damage your power sensor. But out of focus, the beam is simply too big to fit into a standard power sensor.

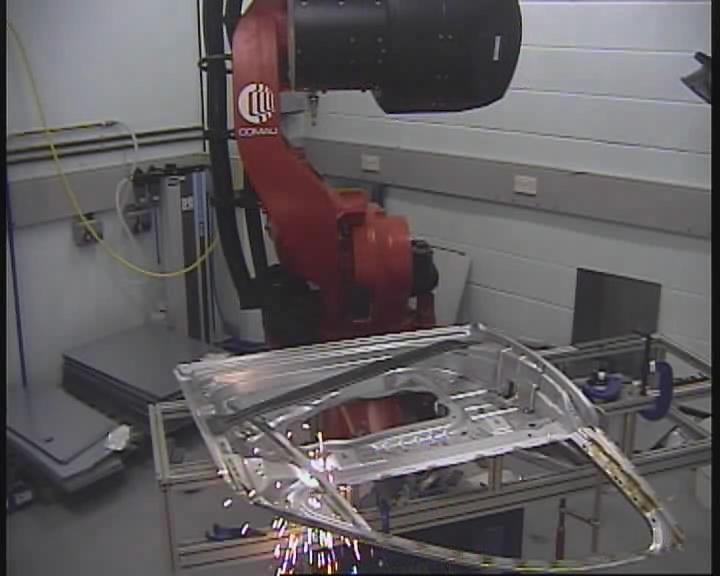

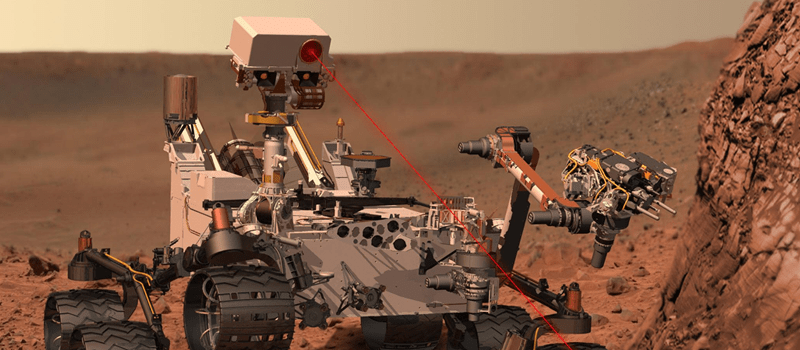

A laser welding a steel car door at the University of Warwick

At Ophir, we realized this could be an issue and set out to solve the problem.

To increase the damage threshold we need to find a new sensor coating or technology. Of course, we’re always looking for newer, better sensor technology, but that’s not the kind of thing you can just produce on demand.

A much easier solution is to just make a bigger sensor. It’s heavier, and it’s bulkier, but if you need a large aperture, you can’t do better than 120 mm. Well, I guess you can always go bigger, but at more than twice the size of most other Ophir sensor apertures, we figured this will cover most of your needs.

Ever get stuck like the laser technician in my story? Ever feel like there was just no way to measure your laser? Let me know in the comments.

Dear Sir,

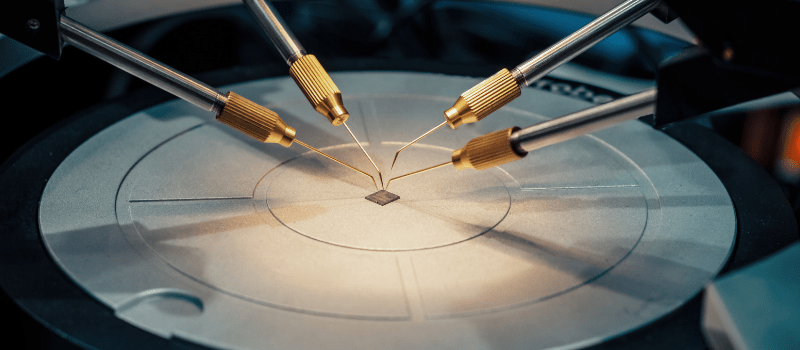

I have a Gras20 CCD for measuring M2 (beam quality).

Recently if I start to measuring M2 with M-200s software manualy, ultracall can not work properly and say block the laser. I blocked the laser and completly close the ccd aperture then ultracall say block the laser! Ultracal in the beamgage works properly but in the m-200s send this message. what is the problem. I uninstalled and installed again m-200 and problem exists.

Hi Rob, I’m going to look into this for you and I’ll try to have an answer for you by Sunday/Monday.

Sorry for the wait, I was checking with Ryan Weekes, one of our experts in beam profiling. Here’s what he said:

“There are some bad pixels that have developed on the CCD imager that are exceeding the allowable intensity level that the M2-200s software permits. BeamGage has a slightly higher level of what it will allow. Both programs will attempt to zero the pixel, but if the digital count of the pixel is too high, it will post this error.

You should send the camera back for inspection and correction of the bad pixels. It would also be a good idea to send back the M2-200s system at the same time for recalibration.”

You can find more information on how to send it in for repair and recalibration here: https://www.ophiropt.com/laser-measurement-instruments/customer-support/customer-support/rma-bp

All the best,

Effy