When using power sensors and meters to measure laser power, the million dollar question is: How accurate are the results?

To help answer this question, let’s examine everything that goes into an Ophir power sensor accuracy specification (as well as related specs, like linearity).

The single biggest factor that will determine the sensor accuracy is its “calibration uncertainty.” Other factors include:

- Wavelength dependence

- Linearity

- Uniformity (over the surface of the sensor)

- Pulse rate dependence

- Display unit (power meter) calibration uncertainty

- Damage to the sensor’s absorber surface

- Electromagnetic interference

Calibration Uncertainty

Ophir calibrates all its sensors against master sensors, which in turn trace their own accuracy to calibration against an international standard sensor (such as NIST). This creates a trail of calibration, each step producing some level of uncertainty based on the calibration setup, which can be calculated with statistical analysis.

In most cases, this is enough to provide the sensor with its accuracy specification, as the other factors listed above are often negligible. However, it is still important to understand them in order to avoid situations when they will provide significant losses in accuracy.

Wavelength Dependence

Sensors are not always uniform across different wavelengths. Generally, Ophir takes two approaches to this problem:

- For sensors with a broad spectrum of near-uniform response, Ophir defines discrete wavelength ranges that can be selected by the user. Each of these ranges are calibrated separately. If the difference in absorption between one point in that range and the wavelength at which the sensor was calibrated is greater than 1-2%, Ophir adds this error to the specification. If it is less than that, it does not contribute to the overall error.

- For sensors with a more varied spectral response, Ophir defines a continuous calibration curve covering the variations at all wavelengths in the region.

Linearity

Linearity becomes predominant only at powers closer to the maximum power. For more information, consult your specific sensor spec. (Photodiode sensors do not include this specification, but it is always less than ±1% except very close to maximum power.)

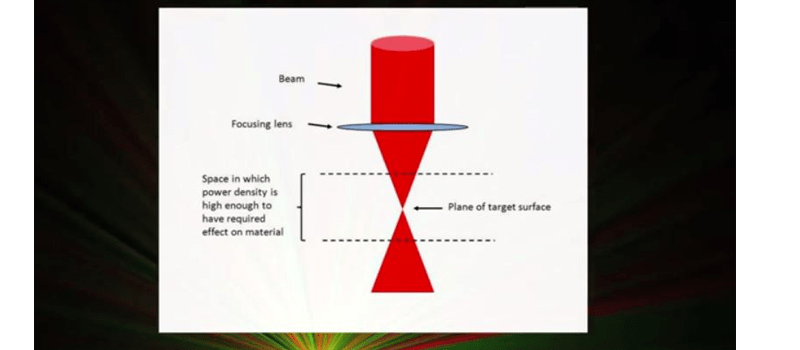

Uniformity

Uniformity is not usually mentioned in Ophir specifications. However, these two guiding principles should help:

- In most cases, uniformity in the central half of the sensor area is ±2% maximum variation. Often, it is better than this.

- If your laser beam is both centered and no more than 25% the area of the sensor, you may disregard any additional uniformity concerns.

Pulse Rate Dependence

Pyroelectric energy sensors pulse rate dependence come into play most significantly when the pulse rate is between 70-100% of the maximum, at which point the additional error will be close to the maximum pulse rate error in the specifications. At lower pulse rates, the error will be quite low.

Display Unit Calibration Uncertainty

In general, the error of calibration of the display is much smaller than the calibration uncertainty of the sensor and therefore can be ignored in most cases.

Sensor Damage

If you notice a burn spot or other blemish on your sensor, you can determine whether or not it affects the accuracy by moving a laser away from and back to the damaged spot. If the laser reads the same, the damage is cosmetic only. Note: Ophir damage threshold specifications are the point at which the sensor damage could cause a change of 1% or more to the reading. It is possible to notice cosmetic damage below this point.

Electromagnetic Interference

Ophir meters and sensors are certified to meet CE requirements for susceptibility to and emission of electromagnetic radiation. At almost all frequencies of radiation of strength up to the limit prescribed by CE, one will not notice any interference.

For Dr. Ephraim Greenfield’s in-depth treatment of Ophir calibration procedure and error analysis, see the full article here.

Leave a Reply

Your email address will not be published. Required fields are marked *