Pulsed lasers are complicated.

When you’re dealing with a CW (continuous wave) laser, things are nice and simple. The laser light has a certain power, and that’s exactly what you’re measuring with your laser power meter.

But a pulsed laser is much more complex. Besides power, you also need to worry about pulse energy, frequency, and pulse width (duration).

Now, if you’re looking to measure energy per pulse, you’re going to need to look at all those parameters. (Find out more about measuring laser energy.)

But let’s assume instead that you’re just interested in keeping track of the laser’s average power. Since you’re measuring power, I’m assuming you’re going to use a photodiode or thermal sensor (although you could also use a pyro sensor).

Remember that these sensors don’t even “realize” the laser is pulsing. They don’t care whether there are two 40 μJ pulses per second or one 80 μJ pulse per second. For this reason, frequency and pulse width are irrelevant. There’s no maximum since – on the contrary – a longer pulse or faster frequency just approaches CW, which is fine by us. There’s also no minimum pulse width since we don’t need to worry about the sensor responding to the pulse in time – it’s not going to respond to that particular pulse (in time) but to the average power which gets smoothed out by the thermal sensor.

Caveats

- Pulse energy:

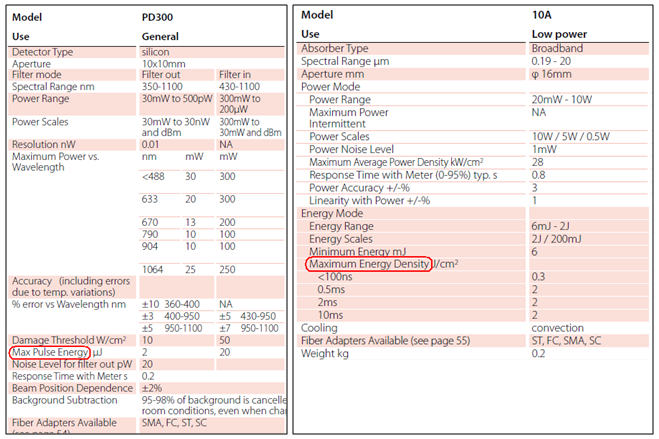

Although you may have no desire to measure the pulse energy, if it’s too high it could damage the sensor. All Ophir power sensors have a stated maximum pulse energy or energy density that depends on the pulse width.

Specification sheets for photodiode and thermal sensors, indicating the maximum energy levels permitted

2. Low Frequency:

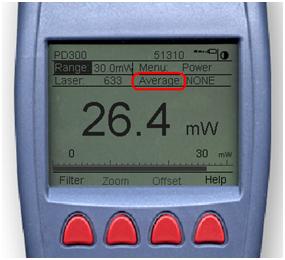

When using a photodiode sensor for a low-frequency pulsed laser beam (under about 100 Hz), it may be difficult to get a steady reading. This is caused by a beat frequency between the laser and the analog-digital converter (which samples at 15 Hz). In many cases this can be alleviated by using the meter’s averaging function.

There will always be more information than you need. There’s too much info on the net, too many emails in your inbox, and yes, too many parameters in the datasheet.

The key is knowing which ones you need.

Questions?

Ask me in the comment section

You might also like to read:

How to use a thermal sensor for a pulsed laser beam

How to measure the peak power of a pulsed laser?

if i do not have a thermal sensor as the one above , how can i measure the energy for example 50 , 200 ,1000 pulses ?

Hi Mary.

I’m not sure I understand your question. You say you do not have a thermal sensor; what type of sensor do you have?

To measure energy per pulse of a repetitively pulsed beam, one typically uses a pyroelectric type sensor; thermal sensors are used for measuring average power of a CW or a repetitively pulsed beam, and they can also be used for measuring energy of a “single shot” pulse – meaning a single pulse fired once (with at least 4-5 seconds before another pulse can be fired again). The thermal time constant of such sensors is on the order of seconds, so if the group of pulses you ask about are “packaged” together as a burst not longer than about 1 second, the sensor will “see” that burst as 1 single long “pulse” and measure its total energy.

If, on the other hand, you are using a suitable pyroelectric type energy sensor, then it will respond to every single pulse; if by your question you mean that you need to measure the total energy in any given set of n pulses, it becomes just a question of a suitable function in the meter you use with the sensor. In most Ophir meters, we have a function called “Exposure”, which measures and adds up energy over a given number of pulses, a given timeout, or after a manual “Stop” button is pressed.

Mark Slutzk,Product Manager for Power and Energy Measurement Solutions, Ophir Optronics Solutions Ltd.

Do you have some power meter that can detect laser power of femtowatt/picowatt range.

Hi Geetanjali,

Yes, we do.

Several models of our photodiode-based PD300 family of sensors can measure down to ten or several tens of pW; examples include the PD300-UV (UV-enhanced silicon) and the PD300-IRG (InGaAs).

Also, the RM9-PD radiometer system can measure powers down to 300 fW.

We are now seeking for the suitable power measurement sensor for 10 Hz, high intensity pulse(pulse duration: 4 ns).

To brief our circumstances, we are using large core fiber(1000 um, single) to deliver ~ 150 mJ at max., and trying to measure the output power at the proximal end.

As so, the output beam will be diverging & small (diameter ~ 3 mm) and blinks in 10 Hz.

We have been trying with commercial powermeter probes, which are intended to measure CW as you mentioned,

however due to the small beam dimension & low pulse rate(10Hz), it did not come to be successful.

What is your recommendation for such high intensity, low frequency pulse laser?