Read all about Ophir’s new sensor that measures high-power ultrashort-pulse lasers and is ideal for use in micromachining and material microprocessing applications in the semiconductor, display, and medical industries.

Ophir’s absorbers – cover the wavelengths stretching from UV to the long-wavelength IR regions

Ophir offers several unique absorbers for its wide variety of power sensors, each optimized for different purpose; whether you want to measure the power emitted by broadband light sources, high power lasers, or even faint light sources, you can find a sensor equipped with the proper absorber for your application.

Ophir’s absorbers cover the wavelengths stretching from UV to the long-wavelength IR regions, and they can measure almost every industrial laser in the market. But every now and then we develop a new absorber which stands out from its older siblings and makes its way into our product list.

Introducing the NEW F80(120)A-CM-17

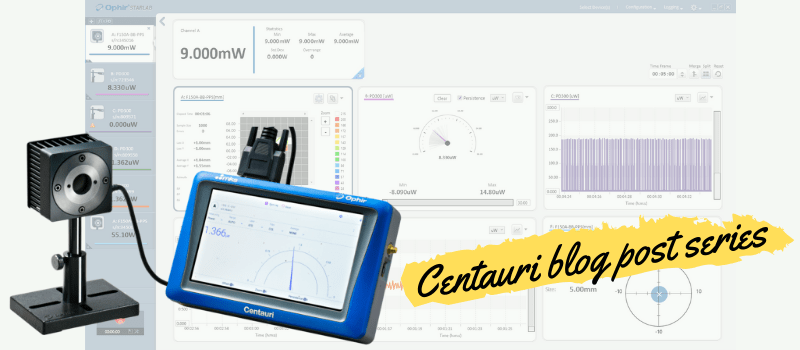

Today, we are proud to announce a new power meter, F80(120)A-CM-17 , based on our latest CM absorber. In this blog post we will discuss its benefits and advantages for certain applications, such as measuring high repetition rate pulsed lasers.

First, some general details – sensor has a 17.5 mm aperture and can measure laser light in the wavelength range 248 nm to 9.4 mµm.

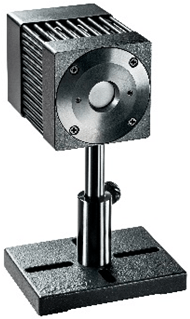

With its fan-cooled design this power meter withstands up to 80 Watts average power (and up to 120W intermittently) with very high power densities, depending on the exact laser parameters. It is supported by all of Ophir meters (e.g., StarLite, Juno+). Its image is presented in Fig. 1.

Let’s focus on the main feature of Ophir’s new CM absorber

Our tests have shown that it is especially tailored to measure CW lasers and high repetition rate pulsed lasers.

The latter are characterized by pulse rates up to hundreds of KHz with relatively low energy per pulse, but with high instantaneous power (due to their short pulse duration, up to tens of nanoseconds).

When discussing the maximal average power that a sensor can withstand, we usually consider its mechanical design since that determines the heat dissipation mechanism.

However, care must also be taken concerning the light’s wavelength and instantaneous power, and we need to ensure that its readings are stable in time and that no degradation to the absorber occurs. Since the light’s wavelength is inversely proportional to the photon’s energy, it is not surprising that short wavelength lasers are prone to damage absorbers much more than long wavelength lasers with the same power. On the other hand, these short-wavelength lasers offer a huge advantage since they can be focused into smaller beam spots.

Moreover, some applications rely on short wavelength light for other reasons (higher absorption, more efficient light-matter interaction). These demands have triggered the development of short-wavelength lasers with increasing powers and raise the need for suitable sensors.

Ophir’s new CM absorber handles light in the UV range (e.g., 355 nm) making the F80(120)A-CM-17 an ideal sensor for measuring average powers of tens of Watts, even for pulsed lasers with short pulse duration. With its >80% absorption above 300 nm and thanks to Ophir’s NIST-traceable calibration, this absorber is capable of accurately measuring the most powerful high-repetition rate nanosecond pulsed lasers available in the market today.

Leave a Reply

Your email address will not be published. Required fields are marked *