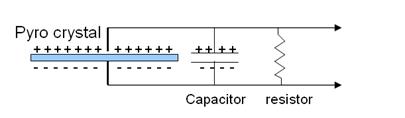

Pyroelectric energy sensors are based on the principle that heat polarizes a pyroelectric crystal thereby causing generation of an electric charge proportional to the heat absorbed in the crystal. The simplest form of pyroelectric energy detector will then be a thin pyroelectric crystal, metalized on both faces to collect the charge generated with a parallel capacitor to produce a voltage proportional to the energy and a parallel resistor to bleed off the generated charge to be ready for the next pulse. This is shown in the following figure:

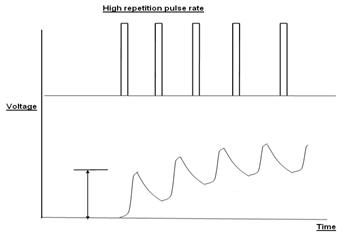

The above system works well for short duration pulses and low repetition rates i.e. low duty cycle, where the time between pulses is long compared to the duration of the pulse, at least 10:1 and preferably much more than that. If, however, the duty cycle is shorter, then nonlinear effects come in as shown in the following figure:

We see that several problems happen:

- The voltage can start decaying before the laser pulse is finished thus causing a low reading of energy.

- The voltage has not decayed before the next pulse comes in so the reading starts from a nonzero point.

- The crystal is hot from previous pulses so when the next pulse comes in, as well as the crystal heating up from the new pulse, it is at the same time cooling off from previous pulses. Thus the difference in temperature between before and after the pulse is less than with a cold crystal and hence the energy reading will be lower as well.

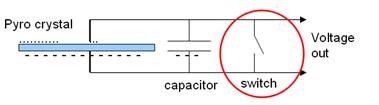

Ophir has attacked these problems with a sophisticated electronic circuit built into the sensor head. The basic solution is instead of a fixed resistor to bleed off the charge, the circuit keeps high impedance during the pulse, so the charge will not bleed off and low impedance between pulses so the crystal will be ready for the next pulse immediately after the end of the previous pulse. This is accomplished by a proprietary and complicated circuit including among other things negative feedback but is illustrated schematically in the following image as a switch opening and closing:

The above method results in dramatic improvements in performance. Instead of 5-10% duty cycle, we can get close to 50% duty cycle. Instead of a fixed trade off between maximum pulse width capability and maximum repetition rate, we can arrange the circuit to measure long pulses at low repetition rates and short pulses at high repetition rates where the user chooses the maximum pulse width setting. In the same sensor we can get repetition rates as high as 10 KHz and pulse widths as long as 5ms. For a high repetition rate detector, this is more than 100 times the maximum pulse width available from traditional non switchable methods.

The above method also optimizes noise behavior since for short pulses the integration time can be short, minimizing noise. This results in a larger dynamic range of maximum to minimum measurable energy as well.

Ophirs most recent series of pyroelectric sensors, the compact C line, uses this advanced technology along with upgraded electronics and mechanics with superior performance in every way: more compact, wider dynamic range, higher repetition rates and can measure longer pulses.

You might also like to read: How to measure the peak power of a pulsed laser?

Share this:

thank you for this post, I am a big fan of thgis internrt site would like to continue updated.

Hi,

Thank you for your kind response.

We are happy to know you find our blog post relevant and efficient.

Feel free to keep sharing your thoughts with us in the future!

Well I definitely enjoyed reading it.This subjeect offered by you iss very practical for correct planning.

Only wannna input that you have a vsry nice internet site, I enjoy the style it actually stands out.