Whether your laser beam applications are used for the medical, industrial, electronic, automotive, or defense industries, beam profiling is crucial to maintain the integrity of the laser.

What is a Beam Profiler?

Simply put, beam profiling is the process of measuring and analyzing the characteristics of a laser beam shape, with a primary goal of understanding the quality and performance of the laser beam shape in real time.

Beam profiling typically involves capturing the spatial distribution or intensity of the beam. Measurement of the beam can be in width or diameter, measured as small as microns or as large as centimeters and the beam profiler offers data on how power is distributed in the beam itself.

Beam profilers ought to be able to analyze large or small beams, from pulsed or CW sources.

And equally important, they must be able to measure any kind of power, from microwatts to kilowatts.

Unlocking Precision: Why Every Laser Application Needs a Beam Profiler

Today’s competitive market, regardless of the industry, rewards higher profitability. Anything that drives profitability makes a difference.

To achieve higher production rates, you need higher speed processing. For more reliable lasers, you must reduce maintenance downtime. For consistent performance, there needs to be less variation during processing. To operate at maximum efficiency, the laser must be well-tuned for each operation.

If you want to be profitable, your laser must be productive, efficient, and exacting. And you must do it consistently, day after day, hour after hour, with as little down time as possible, with as little waste as possible, and as close to zero defects.

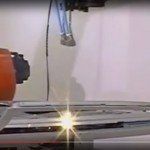

Industrial manufacturer applications cannot afford downtime on their production line and medical applications can never afford health-related errors. In essence, every industry benefits from better welds, increased production, and higher ROI.

The best and most effective way to get these results is to use profilers that measure all the time so you only have to trust once.

Outdated and Outclassed: The Limitations of Non-Electronic Beam Profiling

Electronic laser beam profiling became commonplace in the late 20th century, when technological advancements in cameras and computer software and hardware, began to take off.

Before these technological advancements, laser profiling was a fairly rudimentary process.

For example, the “burning paper” technique, quite literally, involved burning paper. The laser beam would target a piece of paper and burn a hole through it to roughly measure the beam size and some beam structure. But the technique wasn’t enough to produce quantitative numbers nor was it able to show hot spots or holes from a misaligned beam.

Fluorescent cards were leveraged to produce a visible light when exposed to certain light wavelengths. Burns on fluorescent cards offered the ability to see many orders of magnitude in signal intensity, but it could not be used in high power CO₂ applications, and the eye was not able discern changes in beam intensity that were too small while also giving the impression that the beam was larger in width.

Then there was beam measurement on acrylic, a transparent plastic that created a visible change in the acrylic’s surface, such as discoloration or actual physical damage. While this technique worked well for CO2 applications, and showed structural information with some rough quantitative measurements, it only represented an average over time, it was time-consuming, and it released toxic fumes.

Evolution From Analog to Digital: Today’s Laser Beam Profilers

Technology has improved sufficiently and industry effectively migrated from the ‘analog’ version of laser beam profiling to the ‘digital’ method. Over the last 10 years, newer techniques made real-time data gathering easier and more useful than it once was, particularly with innovations in both hardware and software.

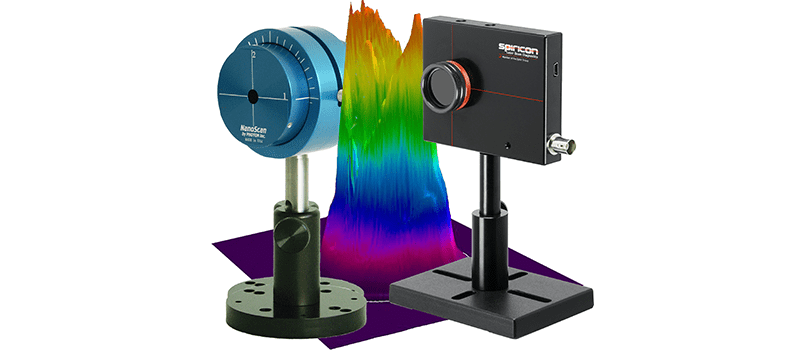

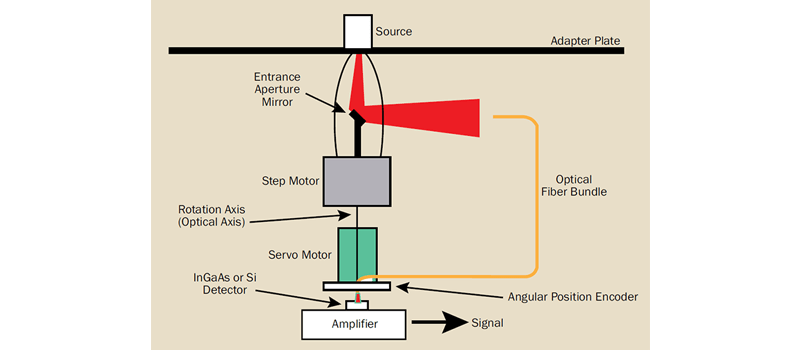

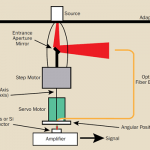

The Ophir family of profilers includes camera-based, nano-scan profilers, high-powered profilers and beam-squared profilers.

To learn more about our camera-based laser beam profilers, click here. For information on our unique BeamSquared laser profiler and related software, click here.

Leave a Reply

Your email address will not be published. Required fields are marked *