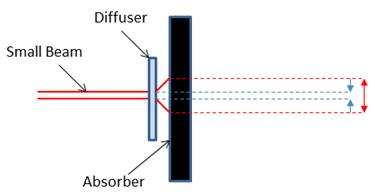

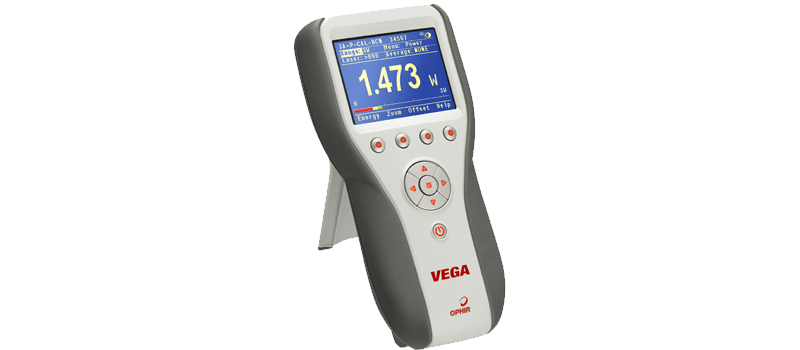

When trying to measure a high energy density laser, it can damage your laser energy sensor if you’re not careful. When the density is a bigger problem than the energy level itself, a diffuser is usually the best solution. Here’s how it works:

A Laser Energy Sensor with a Diffuser

The diffuser spreads out the light to increase the size of the laser beam. Since energy density is energy divided by cross-sectional area, we can lower the energy density without touching the energy, simply by increasing the beam size.

Okay, so diffusers are good.

Now I’d like to tell you what NOT to do with your diffuser.

#1 – Beware of Off-Center-ness

As you can see from the diagram above, a diffuser spreads out the beam in all directions. If the diffuser is the same size as the sensor aperture and you shine your laser at the edge of the diffuser, it shouldn’t be hard to imagine that much of your beam will miss the sensor. This will (of course) result in an incorrect energy reading.

To be fair, though, this isn’t really something that you should have to worry about, since Ophir already compensated for this potential hazard by making the diffusers smaller than the aperture.

However, I still suggest having this concern on your radar when using diffusers – especially if you have an OEM product, which may be constructed in an unusual manner based on the customer’s individual needs.

#2 – Derate for Large Beams

This is one of those statements which seem completely backwards at first, but upon closer examination, it becomes clear and almost seems obvious after-the-fact.

Okay, someone has to ask the question: If the whole point of a diffuser is to make a beam larger, shouldn’t a larger beam be even better?

Now, there is some truth to the question. If a laser beam is bigger, its energy density is generally smaller. If the energy density is small enough, you don’t need a diffuser in the first place. (This is the case for most large beams.)

If, however, you have a large beam AND a high energy density, then the diffuser is not as effective as it would be with a small beam, and must be derated (i.e., the maximum energy density or damage threshold is lower).

Why?

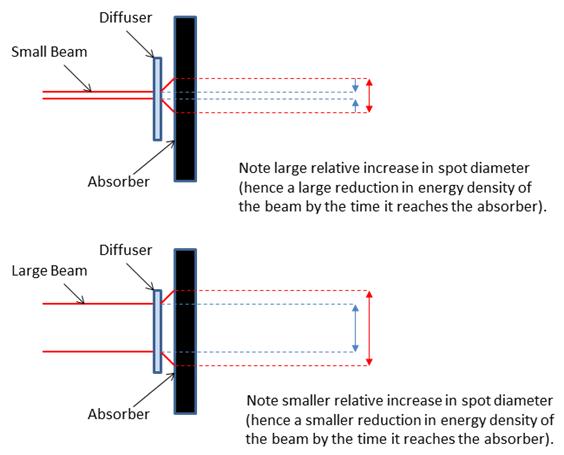

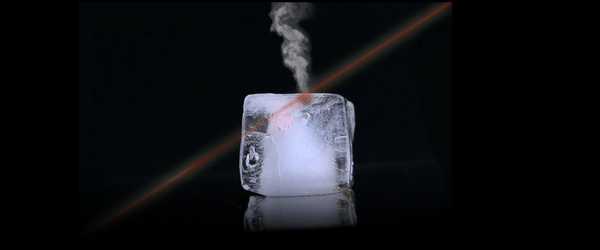

Comparison of Using Diffusers with Lasers of Different Beam Sizes

We see from these two figures that the diffuser and the space between it and the sensor are constant, but the beam size changes from one figure to the next. Since we’re using the same diffuser, the beam width is increase by the same amount. However, relatively speaking, it’s very different.

Let’s use an example: Say the first beam is 2mm (diameter) and the seconds is 10mm. Both beams have the same energy density of 10 J/cm2. Also, let’s assume the diffuser increases the size by 2mm. In the case of the first figure, the laser’s diameter is increased by a factor of 2, increasing its area by a factor of 4. In the second, the area is only increased by 1.44.

Bottom line: The first laser beam hits the sensor with an energy density of 2.5 J/cm2, while the other has almost 7 J/cm2.

So once again, diffusers are good. But now that you know how not to use them, they’re even better!

You might also like to read:

A shortcut for calculating Power Density of a laser beam How to choose the energy level and threshold

Completely, agree. Due to power density of an OEM product line I dealt with for years, we religiously damaged detectors. Started using sand blasted microscope slides, and then moved to the ground lens from a retailer. Saved thousands on detector replacement, the couple of bucks a piece over thousands of hours of burn-in, well worth it. The thermopile style detectors are not capable of handling even moderate power densities CW over long term. You will eventual damage the radiated area if you are fixture to the same target area, this idea takes care of it.

Good article to save money and detectors from damage.