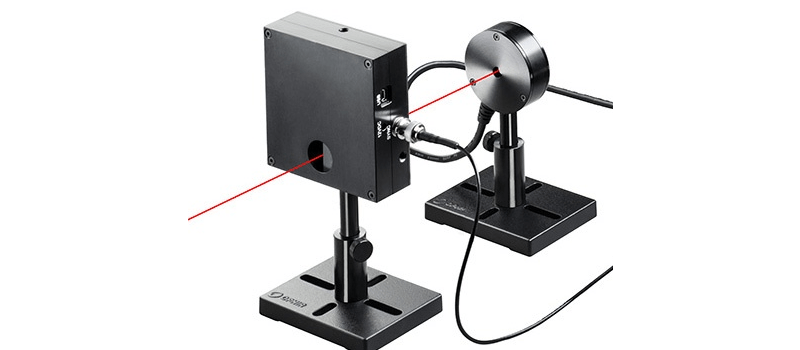

On the one hand, CW lasers will almost always have a higher average power. That means it’s harder for the power sensor head to cool down.

This is not an issue with most short pulsed lasers.

However, a pulsed laser could deposit a large amount of energy in a very short time. The short time means the laser energy doesn’t have time to penetrate far into the absorber. If you used our standard broadband coating for this laser, it would absorb all that energy in a layer of about 0.1 μm thick. Too much energy in too small an area will ruin the absorber.

So this begs the question: How can you measure a short pulsed laser beam (with relatively high energy pulses)?

The answer – don’t use a regular BB absorber. Use a volume absorber, such as a PF coating with high power density.

The PF coating let’s some light in, so instead of a 0.1 μm absorbing layer, it absorbs in a few tens of microns. And now that the energy has more room to be absorbed, it is less likely to cause any problems.

So back to our question: Which laser is harder to measure – pulsed or CW?

Neither.

Just make sure you use the right sensor for the job.

Flickr creative commons picture via Naval Surface Warfare Center (NSWC), Corona Division

Leave a Reply

Your email address will not be published. Required fields are marked *