We introduce three techniques for monitoring the critical characteristics of the beam as the laser is used in three very different applications: (a) VSCEL / Laser Diode Mode and beam divergence, (b) Additive Manufacturing lasers used is 3D SLM / SLS, and (c) Fiber welding / heat treating / cleaning lasers.

We will discuss three techniques that monitor the critical characteristics of the beam as the laser is used in three very different applications.

Three techniques that monitor the critical characteristics of the beam

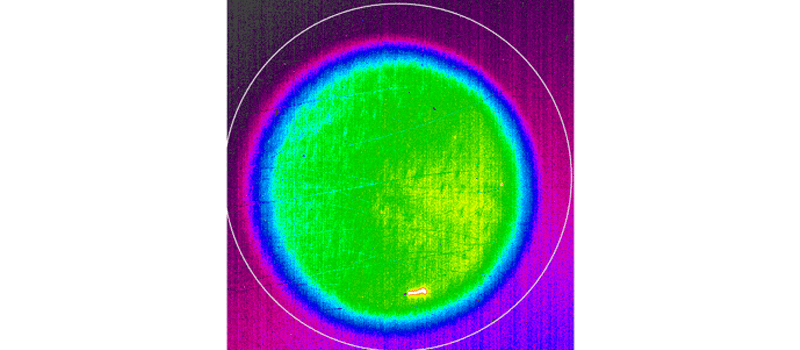

The first technique is to measure the distribution of light from laser diodes or a light source where the light is emanating from a micro-planar surface or edge. Though the light spreads quickly from these devices, the central rays are easy to accurately detect.

The measurement is complicated by the shallow-angle rays of light that occur on the edges of the light cone.

These rays are more easily reflected from detector surfaces, thus are typically under-reported in most direct-to-camera beam profiling techniques.

The Ophir Wide Beam Imager (WB-I) provides a large measurement area where these rays are correctly measured.

The second laser measurement technique is for use with laser metal powder bed 3D printing. Technologies used here are known as direct metal laser sintering (DMLS) and direct metal sintering (DMS), where a three-dimensional object is “printed” one very thin layer at a time.

These types of applications require control of the location of the focused laser spot as well as knowledge of the irradiance or power density of the delivered beam.

The Ophir BeamWatch AM continuously monitors the laser beam about the focal region, measuring the size and location of the focus spot referenced to the powder bed surface without touching the beam in the process.

The third laser measurement technique enables the measurement of the size and location of the focus beam profile of multi-kilowatt industrial fiber lasers. The Ophir BeamGage system with LBS-300HP high power laser beam attenuator helps to locate the focal plane. In this case, by measuring one plane at a time along the beam’s path with the ability to measure the extremely high irradiance of a focused multi-kilowatt laser.

If you’re interested to learn about these 3 scenarios in more detail, read full article here…

Leave a Reply

Your email address will not be published. Required fields are marked *