They say that an ounce of prevention is worth a pound of cure. And the same goes for your thermal sensors.

Sometimes, you can use your thermal sensors for years without the need for repairs. But when we receive these sensors for calibration, we can often tell that misuse led to the sensor’s deterioration.

Here are 3 things that can help prevent deterioration of your thermal sensors.

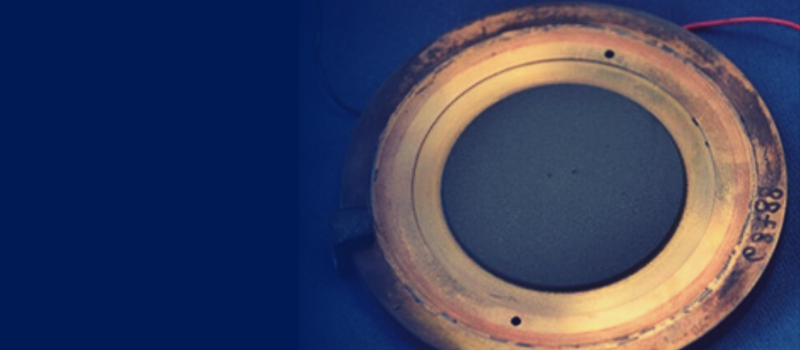

A surface that remains clean from contamination

Firstly, keep the sensor disc clean from foreign substances, such as process debris from industrial environments, or organic contaminants that can then be burned onto the disc by subsequent exposure to a laser beam.

So, keep the surface clean and store the sensor properly when it isn’t being used.

Causing overheating

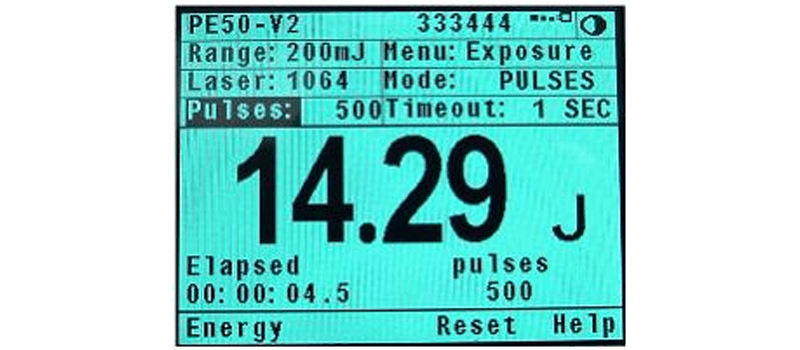

The second cause of deterioration comes when the sensor disc is used at a power level higher than specified, causing overheating.

Major overheating can destroy the detecting element, but even moderate overheating can cause damage to the absorber coating; both will require replacement of the disc.

So, avoid overheating by using the right power levels for continuous use versus those for short term use.

Localized overheating of the coating

Finally, the third cause of sensor deterioration is localized overheating of the coating. It’s the number one cause for disc replacement.

Every coating type has a specific power and energy damage threshold. The spec sheet for each sensor offers guidance on the limits for power and energy damage. Try to stay within those guidelines.

If you follow this advice, it can definitely help prevent the deterioration of your thermal sensor. Read more useful tips on our blog.

Leave a Reply

Your email address will not be published. Required fields are marked *