Part One: Choosing a Laser Power Sensor

If you are a serious laser user, you know how important it is to measure it.

Power is the simplest way to gain an understanding of your laser, although it certainly doesn’t stop there. The only way to get a complete picture is to measure the profile of the laser as well.

But this isn’t a guide to beam profiling, so let’s stay focused on power.

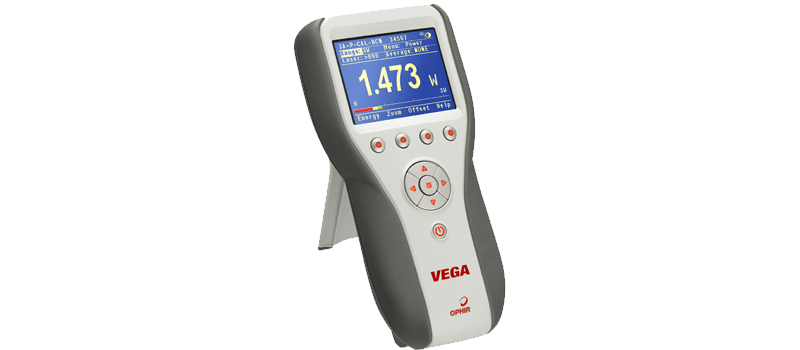

Choosing a Meter

A full measurement system consists of a sensor that transfers the laser energy into electricity. This is then connected to a PC interface or meter (display) which measures the electricity (current) and displays the result.

Choosing a meter or PC interface shouldn’t be very difficult. Each has its own set of functions and pros and cons, which can be used to help you decide.

This chart sums up the interface and meter features pretty nicely.

Choosing a Sensor

Finding the right sensor for your laser is a much trickier task. First, I want to direct you to our sensor finder. Ephraim Greenfield (Ophir CTO) and his team put this together very nicely. Enter your laser parameters, click “find sensor,” and you get a list of the top sensors for your search, with the best match at the top. (It even puts the less expensive sensor first if there are multiple that are “best.”)

The sensor finder is really all that you need to find a sensor, but if you want a bit more background into the kinds of sensors and how to find the best, here are a few guidelines:

You can use a photodiode or thermopile to measure laser power. Photodiodes are much more sensitive and they’re the only solution for very low powers. The complete power range of PD sensors (with and without attenuating filters) is from 10 pW to a few Watts.

Thermal (thermopile-based) sensor can measure from a few μW to hundreds of kW.

For CW beams, there are only a few laser parameters to consider (for both PD and thermal sensors):

- Wavelength: thermal coatings may be broadband or have a more “interesting” spectral response, which covers certain wavelengths. This is a simple check of whether your wavelength is covered. If it is, rest assured the sensor is calibrated at your wavelength or close enough to introduce no more than 1-2% error to the reading.

- Power: power is needed for two reasons. One, each sensor has a power range. The minimum is determined by the sensitivity of the sensor; the maximum is based on its ability to dissipate heat. Second, the maximum power will be used to calculate the damage threshold. (See the next point.)

- Diameter: this is also needed for a couple of reasons: One, if it’s too big, it won’t fit into the aperture. Ideally, its area should be contained in the central 50% of the aperture area for best accuracy. The diameter is also used to calculate the damage threshold. The damage threshold is the W/cm2 (power density) at which damage to the absorber could occur. Spot damage is defined as the point at which the damaged spot is at least 1% off from its surroundings.

For pulsed beams, things get a bit more complicated. I’ll be sure to have a follow up post for measuring pulsed power and energy. Stay tuned.

Want to find out more?

Read Ephraim’s classic article on measurement accuracy to hone in on exactly how accurate your reading is and how you can improve that accuracy.

Watch this video tutorial on using the laser power sensor finder.

Flickr creative commons image via Lauren Macdonald

Hi Effy,

I am beginnner for power metering, despite i’d worked with Starlab 3.0. From the beginning is my problem:

If I only can measute trough the scan head, what is the ideal setting of sensor ?

1. How far should I set the sensor from focuspoint ?

2. I can not produce a point with scan head only small circle- but the mirrors are movig, the spot moving , too.

3. What speed of spot is required ?

4. Can I measure correctly with scanned spot, or should I forgot it ?

Thanks for your reply ! István

Istvan,

Thanks for your comment.

I’m not sure that I understand all of your questions. First off, are you using a power sensor and meter or a NanoScan scanning slit beam profiler? These are very different tools.

You can contact me directly at ephraim.shafner@ophiropt.com and we can discuss this further.

All the best,

Effy