Today, additive manufacturing (AM) is being used on industrial scales and not only to print prototypes, so the quality of the produced parts and the repeatability of the process are now crucial.

A key factor in the quality of the finished AM product is the condition of the laser and optical components used. To ensure proper operation, to optimize the system performance, and to prevent potential quality problems, the laser together with the optical system require periodical monitoring, especially in an industrial environment.

Among the most common malfunctions are laser power degradation, profile distortion due to contamination of optical components, and thermal lensing, which causes focal shift and focal spot enlargement.

All those issues can inhibit fusion between the powder particles, resulting in inferior product quality and diminished reproducibility.

Ophir offers two instruments specifically designed for AM chambers:

- BeamWatch® AM provides contactless, real-time characterization of the entire beam propagation, based on Rayleigh scattering.

- The power measurement is performed via an integrated, fan-cooled thermal sensor. The fan operates only after the BeamWatch AM is extracted from the chamber to avoid blowing the metallic powders around.

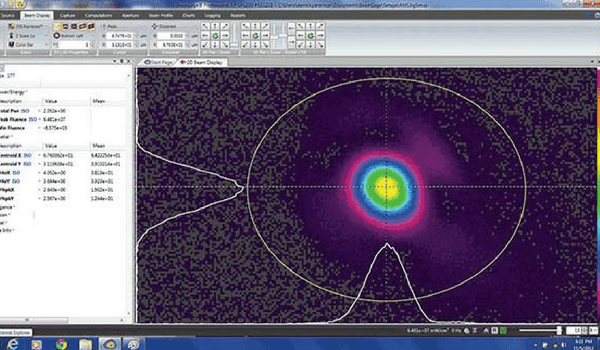

- The BeamPeek™ utilizes a classical method of beam profiling along with a caustic measurement that is performed by moving the build plane within the AM chamber, and the laser power is measured via an integrated thermal sensor.

The specially patented beam dump requires no active cooling and is exchangeable.

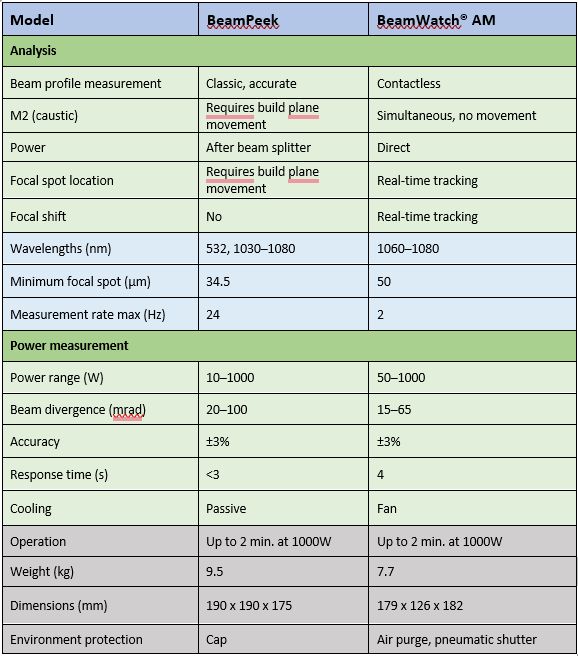

Comparison table between the BeamPeek and the BeamWatch AM:

So, what’s the ideal beam characterization instrument for your AM chamber?

Whether the BeamWatch AM or the BeamPeek is for you depends on the analytical approach and the application.

The BeamWatch AM measures the entire beam caustic at once, from the side, while the BeamPeek requires manual movement of the build plane to perform an accurate caustic measurement slice-by-slice.

That means if overall, simultaneous characterization of the beam and real-time focal shift monitoring are what your application requires, the BeamWatch AM would be a better fit, while for more accurate measurements at different cross-sections of beam propagation, the BeamPeek is the preferred choice.

Additionally, The BeamWatch AM requires compressed air/gas purging, both for its operation and to protect it against metallic powder particles, while the BeamPeek needs no compressed air and its passive beam dump can be swapped out, shortening the time intervals between measurements.

Leave a Reply

Your email address will not be published. Required fields are marked *