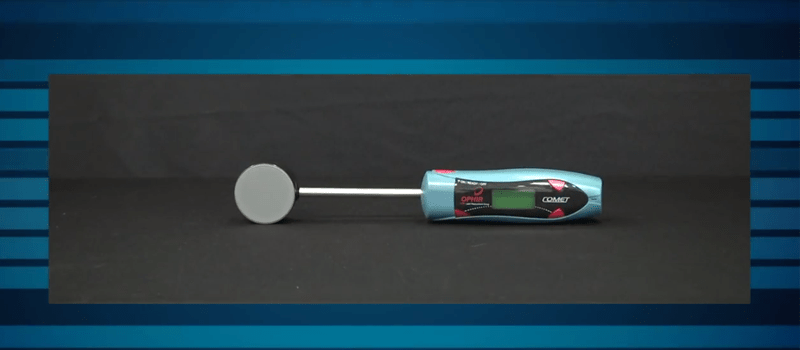

Did you know that a thermal sensor can be used for many years, without the need for a single repair?

Let’s take a look at Ophir’s article on avoiding thermal sensor damage – and find out what expert technicians have to say about keeping your thermal sensors in top condition for years to come.

Why does it happen?

According to the experts, thermal sensor damage comes from incorrect laser optical setup and usage. The articles discusses the most common causes of incorrect usage, and preventative measures you can use to keep your thermal sensors in pristine condition.

Surface contamination

It’s very common for thermal sensors to get dirty. It’s important to find our the source of this contamination – and take measures to prevent it. For example, in the metalworking industry – welding too close to a sensor can easily contaminate it, and should be avoided.

Preventing sensor contamination is easy – clean the sensor regularly, use a protective housing, store it in a clean, closed container when not in use – and avoid touching it with your bare hands.

Overheating the sensor

Another common cause of issues is overheating the sensor. If you use your thermal sensor at power levels that are too high, for a long period of time, you’re likely to see damage to the absorber layer.

And – if your sensor is one that uses thermal grease for thermal coupling – you’ll start to see grease contamination too.

Always keep to the power range and power density threshold listed in the sensor’s specifications.

Some high power sensors require water cooling. You should make sure the water you use meets quality requirements – otherwise it can cause significant damage.

Only deionized and filtered water should be used – the water should be clean, clear, and sediment free and for deionized water it’s also important to maintain a neutral pH level.

When it comes to a damaged sensor – it’s always worth getting it tested – some sensor damage is only cosmetic, and doesn’t affect the reliability of measurement results. Other forms of damage require full sensor disc replacement.

Take a look at the full article to see pictures of different types of sensor damage, and read more details about the measures you can take to keep your sensors in pristine condition.

Leave a Reply

Your email address will not be published. Required fields are marked *