… from any type of source.

Say you need to measure the power of a fiber-coupled UV source. The most obvious choice is to use a photodiode detector, since they are fast and highly sensitive.

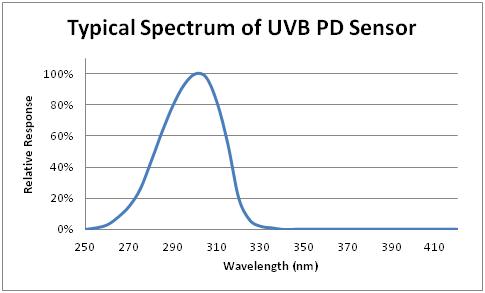

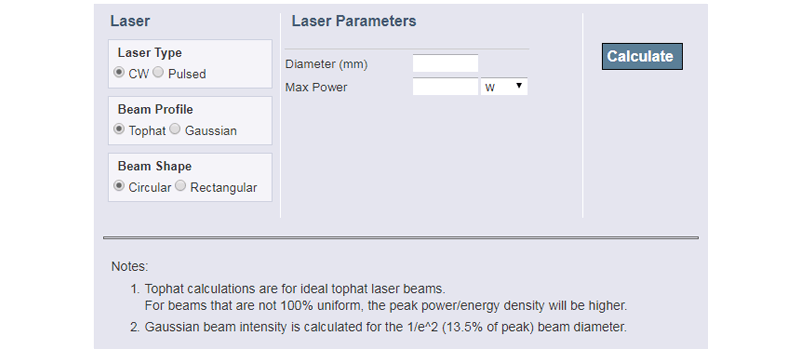

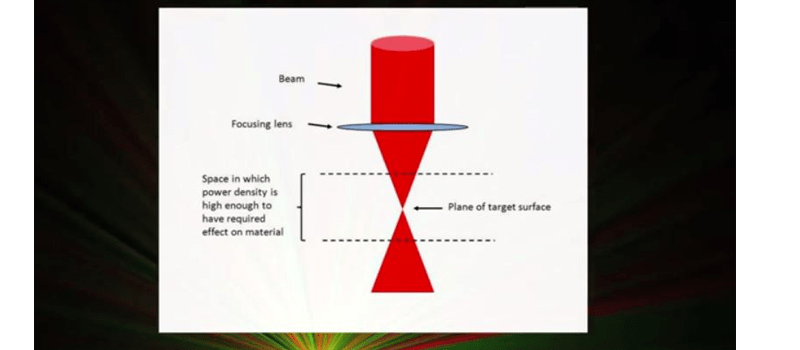

However, you run into an issue with accuracy. PD sensors are highly wavelength-dependent, as shown in the graph below:

At Ophir we calibrate and store the spectral response of our photodiode sensors. This means that if you have a 360 nm source for example, you can enter your wavelength to get a correct reading.

However…

The issue with using photodiodes

This works well for lasers and LEDs with a relatively narrow, well-defined wavelength band. What if you are using a traditional broadband UV source such as a mercury lamp, Xenon lamp, or Deuterium lamp?

One solution is to settle for relative measurements. If you only use mercury lamps you can measure them all assuming that their wavelength responses are roughly the same. You won’t know how much irradiance they output, but you can compare them against each other for relative measurements.

What if you need a higher level of accuracy? What if you want to compare the fiber-coupled power of your old mercury lamp to a new UV LED you want to take its place?

In these cases, a relative measurement without taking wavelength into account won’t work.

What will?

You have two choices for high accuracy UV measurement.

The most complete measurement you can make is with an absolutely calibrated spectrophotometer. Not only will you learn the absolute irradiance of your source, but you can also find out the irradiance contributed by each wavelength. In an application where you really need to know this, spectrophotometers are your only option.

But as I’m sure you know, spectrophotometers are not the cheapest solution. Unless you really need to know the spectrum of your UV source, this is an unnecessary expense.

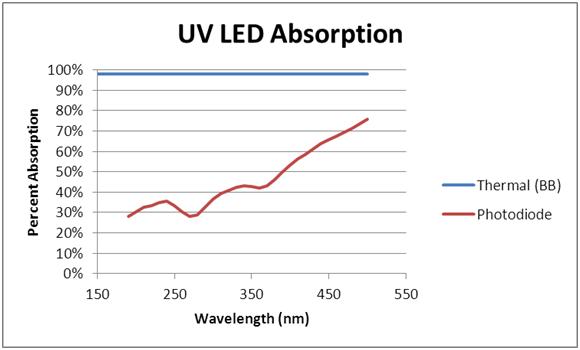

UV absorption of thermal and photodiode sensors

A nice compromise between price and accuracy is a sensitive thermal sensor. Unlike PD detectors, thermal sensors with a broadband coating are almost completely independent of wavelength. Thermal sensors are also less complex and expensive than spectrophotometers. So you don’t get the per-wavelength irradiance, but you can get an accurate measure of the total irradiance, regardless of the wavelength or wavelengths of your source.

Ophir’s 3A thermal sensor is more sensitive than most and can measure powers as low as 10 μW. Also it can measure just about any source in its power range (10 μW – 3 W) provided it’s fiber coupled. That means not only can it measure all types of UV light sources, it can also measure visible and IR sources out to 20 microns.

Bottom line:

An engineer’s cardinal rule is to use the cheapest parts that fulfill the requirements. You know what your requirements are; use this table to decide which form of UV measurement is right for you:

| Price | Accuracy | Measures | |

| PD | Low | Low | Relative irradiance (of similar sources) |

| PD with λ calibration | Low | Medium | Absolute irradiance E of narrowband sources |

| Thermal | Low | High | Absolute irradiance E of any source |

| Spectrophotometer | High | Highest | Absolute spectral irradiance E(λ) |

Contact Efi Rotem for more info on UV measurement.

Leave a Reply

Your email address will not be published. Required fields are marked *