This is a great one.

It’s one of those head-smackingly simple ideas that make you say, “Why didn’t I think of that?”

A Little Trick Goes a Long Way

Here’s how to turn an everyday power meter into a laser power density meter:

Step 1: Take an ordinary power sensor that’s a good fit for your laser power, energy, intensity, wavelength, etc. (Use our sensor finder if you need help.)

Step 2: Cover the aperture with a suitable material (see below), and leave a small window open. If your laser beam is big enough, leave a square centimeter window in the center.

Step 3: Read the output power (in mW, W, or whatever) from your power meter and convert in your head by simply adding “per cm squared.” Since you’re only measuring the power of the part of the laser that passed through the window, you’re clearly measuring the laser’s power density in units of W (or mW) per centimeter squared.

Let’s be more specific. What makes a good “aperture cover”?

First, and this should be obvious, but make sure it can stand up to whatever power your laser is. It wouldn’t do to start a fire just because you wanted to check how powerful your laser is.

So, assuming you’re on top of any possible safety hazards, here’s what you need to check:

1) Use a material that won’t heat up.

It’s actually not enough that the material can withstand the heat. If it heats up at all it will compromise the power sensor’s accuracy, as the sensor will measure heat flow both from the laser and from the new sensor cover. This will affect the power reading.

2) If you can’t find such a material, try using a reflective surface like polished aluminum.

Questions and Tricky Cases

1) Question: What if the entire laser beam is smaller than a centimeter squared? Many lasers aren’t even a millimeter, let alone a centimeter.

Answer: Simply use a smaller window, such that it will only transmit a part of your laser.

The centimeter size is really just to make things simpler, but you can use any size window, as long you know its size precisely. Let’s say it’s a mm2 instead of a cm2. This means your power reading is in units of W/mm2. Truth is, that’s already a power density measurement. But assuming you want to see the more standard units of W/cm2, you just need to multiply by 100 (since 1 cm2 = 100 mm2).

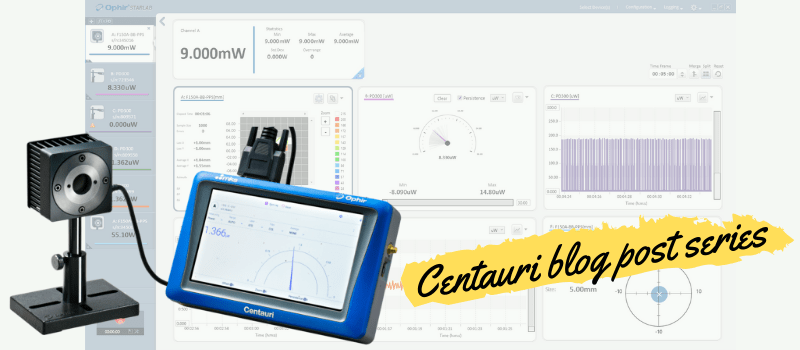

To make things even simpler, the Nova II and Vega power meters come with a power density function (Menu > Density). Enter the beam diameter (or the diameter of your aperture) and the meter will display power density units.

2) Question: What about non-uniform laser beams, such as a Gaussian?

Answer: Well, one option would be to go about it similarly to a uniform beam, but with special care that the center (peak) of the laser beam is focused on the window so you don’t underestimate the power density. The problem is that even within the window it’s doubtful that the power will be uniform.

A better solution would be to use BeamTrack or a full-fledged laser beam profiler to measure the actual beam width and calculate power density from there.

Now I’d like to ask you a question…

You ever come up with a cool laser measurement trick?

Or, did you ever wish there was a simple trick to solve your laser measurement snag?

Let me know in the comments.

I came up with some cool wavefront measurement tricks that we used for a number of adaptive optical systems including the final optical assemblies of the NIF laser and ground based observatories. This was the only way I could find to get a good low power sample from a high power beam;

http://www.google.com/patents/US5410397