What happens when you have an application that requires a specific sensor with respect to technology and mechanical applications?

You know that a standard Ophir sensor works, but you want to tweak the specification and mechanical size a little to fit your application.

Call our representative and ask about customized (OEM) sensors

Recently, a customer called and asked these exact questions.

Knowing that Ophir has customized solution (OEM) prototypes available, the customer asked to evaluate the OEM thermal sensor 20C-UA.

His power requirements at the time were under 20W and the mechanical design needed to be as thin as possible for the application. We took the 20C-UA and programmed the sensor with the values that related to his control system to respond to a specific V/W output from the OEM sensor.

This sensor is basically a thermo sensor: once a laser contacts the absorbing surface, the heat is converted to a voltage and can be read on a meter or a specific feedback device to indicate watts of power from the laser.

This is achieved with an external UA (universal amplifier) board programmed for the specific requirements.

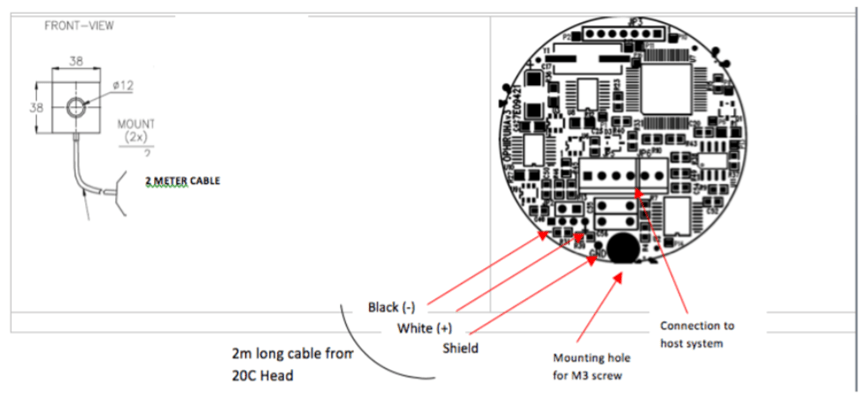

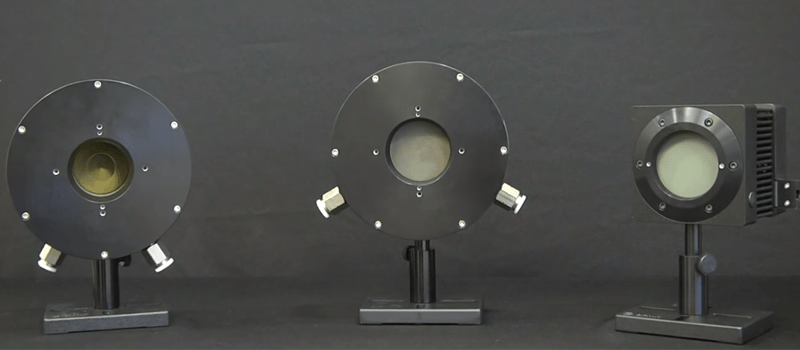

We provided flying leads from the sensor so that the customer could apply the required connector for his application. Following is an example of the sensor configuration:

Specific connector and more power capability

The customer took this demo and determined that they needed a specific connector and more power capability.

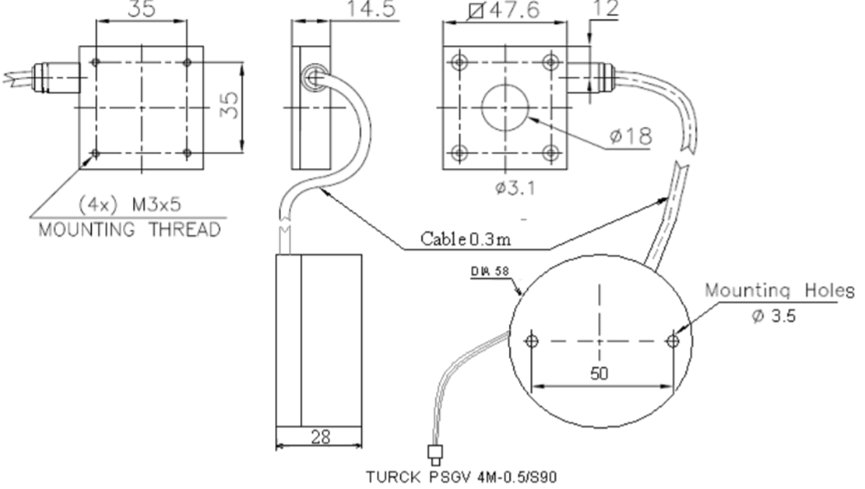

The initial demo/prototype unit was instrumental in determining what was really needed for his application. Further, the thin design of the 20C-UA was of interest and had to be applied moving forward. We regrouped based on this information and developed a new sensor, namely, the 100C-UA-50-535-RE. This sensor took the total power capability from 20W to 100W, a higher range that was within the working interest of the customer moving forward.

The sensor nomenclature is as follows: 100 equals 100 Watts max; C refers to the new low profile version; UA refers to the Universal Amplifier board that is programmable for the specifications required; 50 refers to the sensitivity of the UA board output, namely, 50V/W; 535 refers to the wavelength of calibration for the sensor; RE refers to the remote UA with special cabling for connection to the customers system. The configuration is as below:

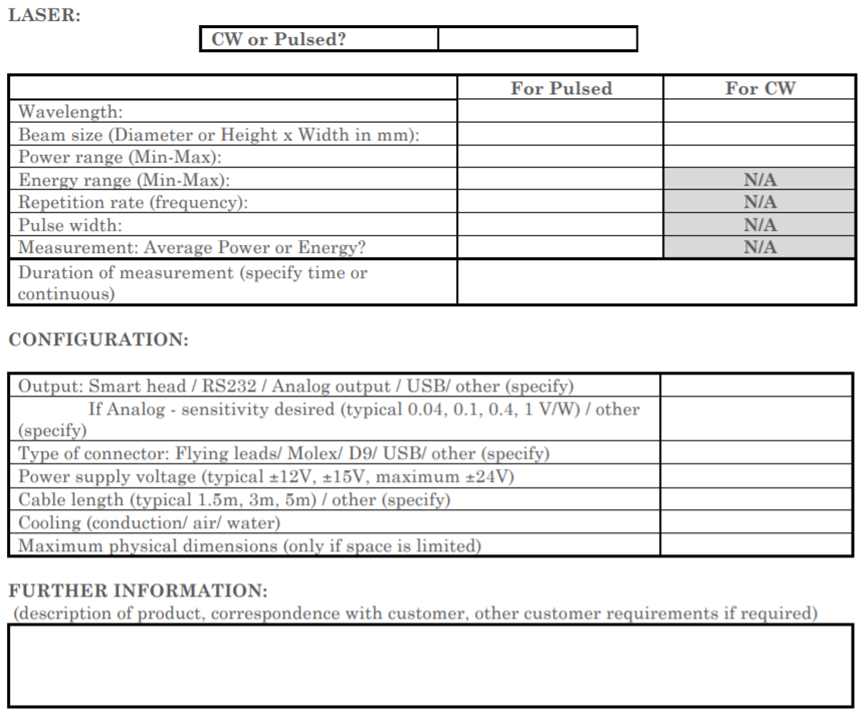

OEM enquiry sheet

This whole process was guided by our OEM enquiry sheet, which defines the specifications and is used as a starting point for such applications. As with all OEM applications, the enquiry sheet can be a document that helps you discover what is really needed, along with ideas for your development. This demo really helped the customer change his design and work toward a better solution.

The OEM enquiry sheet is as follows:

OEM Application Query In order to suggest the best solution to your particular application, please give us the following information. Please note: A fully completed form is essential in order to guarantee the timeliest response.

OEM Application Query In order to suggest the best solution to your particular application, please give us the following information. Please note: A fully completed form is essential in order to guarantee the timeliest response.

Leave a Reply

Your email address will not be published. Required fields are marked *