Electrical cars are all around us.

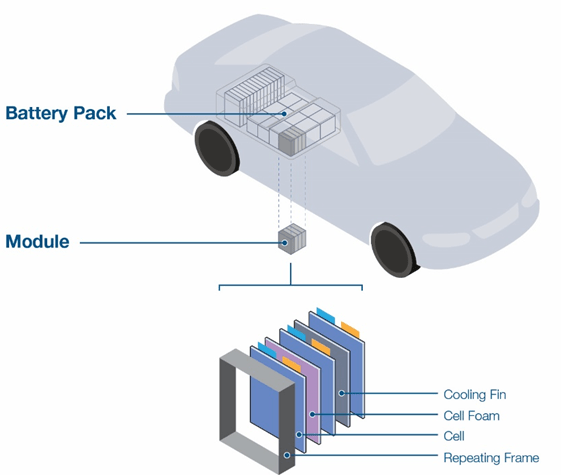

The power source of an electrical car is its Li-ion battery pack. One of the most important parameters for a battery pack is its charge capacity per weight in kWh/kg. This means that battery and car makers want to put in as many ‘battery cells’ (the basic Li-ion unit that stores charge) as possible, and get rid of anything else, such as metal parts that house together several cells in a ‘module’, or several modules in a pack, or the battery pack entirely (i.e. going C2V or ‘cell to vehicle’).

What has that got to do with lasers?

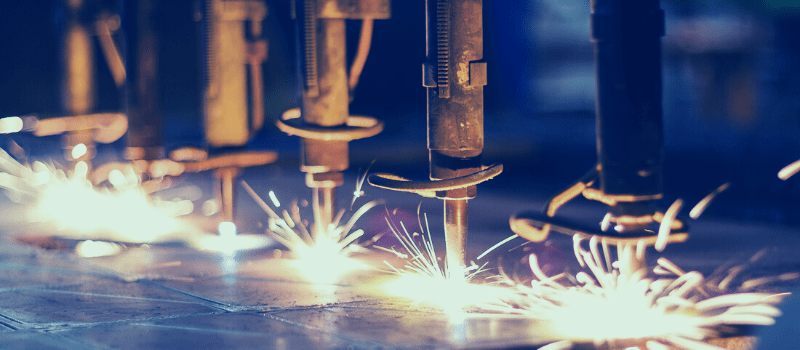

Moving away from a modular approach (cells, modules, battery pack) means that servicing or fixing the battery of an EV car is almost impossible, and therefore the reliability, safety, and structural integrity of the battery must be very high. That is where laser processes come into play.

There are several processes in the manufacturing of the battery pack in which lasers can be used to improved reliability and throughput.

Let’s look at several examples

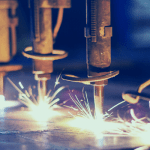

Cutting, cleaning, and welding at the cell level

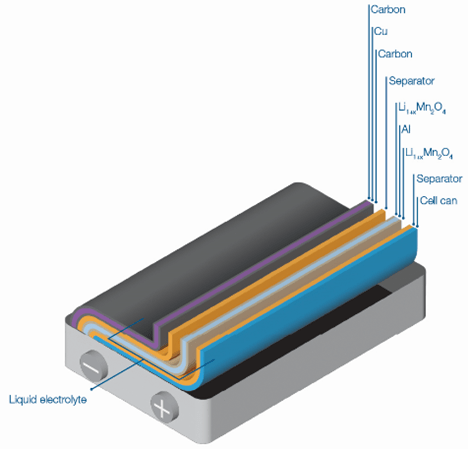

The battery cell is made of three thin foils, anode foil (usually aluminum), separator foil (polypropylene or polyethylene) and cathode foil (usually copper). The anode and cathode foils are coated with a mixture of an active material, conductive agent, and binder. The foils are wound together to make the cell, a positive and negative metal tab is attached to the anode and cathode, and a liquid electrolyte is poured into the cell.

Modern Li-ion battery factories work in a roll-to-roll process, i.e. processing long rolls of the foils for coating, drying, and cutting, before the foils are packed into individual cells.

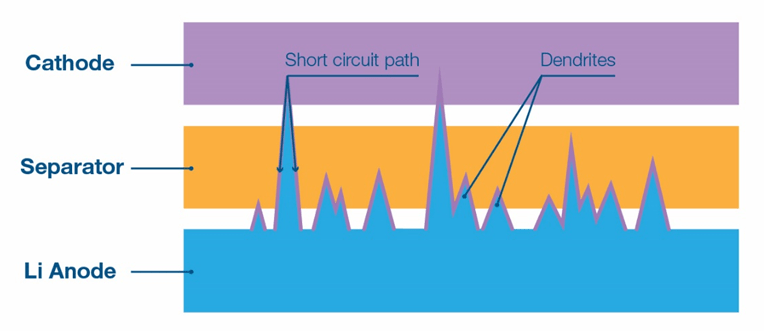

High-power (100’s W) nanosecond pulsed IR and UV lasers are commonly used to cut the foils, clean, and weld the tabs to the anode and cathode. These laser processes have a big advantage over other processes, as they create smoother edges and surfaces which reduce the risk of lithium dendrite formation, a common cause of Li-ion battery failure.

Welding battery pack frame and power harness

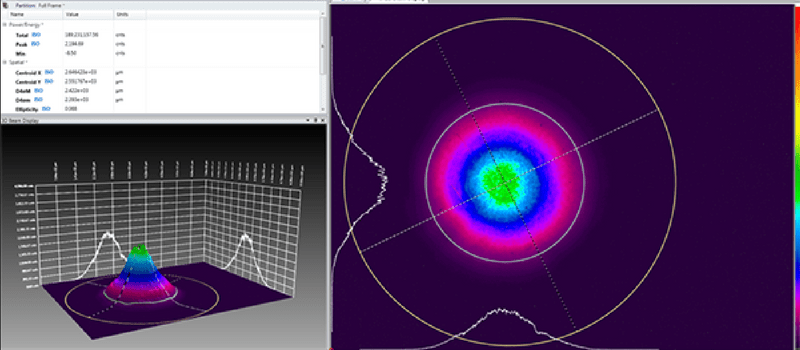

The battery frame holds the cells, modules, coolant lines and power harness. In the C2V concept, this can be a part of the vehicle chassis. Laser welding can produce strong and reliable joints. Traditionally, kilowatt class fiber lasers at a 1 micron wavelength are used. While efficiently absorbed by aluminum and steel, this wavelength is not absorbed by copper, which is used in the power connections. Recently, green (515-535nm, frequency doubled fiber lasers), and blue (450nm direct diode laser) high-power lasers are making their debut, in order to improve the throughput of copper welding. Good welding of different metals is always challenging. A new approach to solving this problem is to control the shape of the laser spot, such as using two spots with different size and power.

Applications currently in research

In addition to current laser applications in battery manufacturing, there are also several applications currently in research. Let’s consider a few:

- Tab-less lithium-ion batteries (patented by Tesla in 2020). Uses a larger battery by removing the tab, allows shorter electron path length. Leads to a larger energy capacity, more power output, and a longer range.

- All solid-state batteries. Replaces liquid electrolyte with a solid electrolyte (usually a ceramic). Solid also acts as a separator (removing the separator foil from the battery construction). Presumably safer construction as it no longer swells due to leak or temperature change. Can lead to higher energy capacity.

- Using high-power ultrafast lasers for nano structuring and texturing of electrode materials. Enables different electrode architectures (3D, holes, grids, lines, etc.) with improved electrochemical performance, reduced mechanical tension during cycling and improved lifetime.

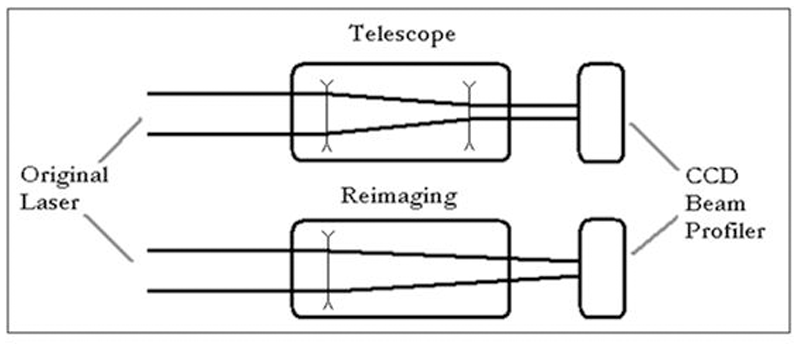

In conclusion, laser applications provide superior reliability and throughput over other methods, and also enable new technologies. The successful utilization of laser processes require precise control of the laser beam parameters such as laser power and beam profile. Ophir Photonics offers instruments and systems for measuring your laser beam parameters and ensuring outstanding performance. https://www.ophiropt.com/laser–measurement/laser-measurement.

Leave a Reply

Your email address will not be published. Required fields are marked *