Picture this:

You’re working on a complicated laser setup, with various beam splitters, attenuation, lenses and mirrors. You spend weeks optimizing the design, and months waiting for all the parts to arrive.

Now everything is here and you set it up with millimeter accuracy.

And then the big moment. Where’s the laser beam?

Try as you might, you can’t find the laser beam and it is far from trivial to determine what part of the design went wrong.

We know this is worse than annoying. It’s a huge headache, and a huge time-suck.

A colleague of mine here at Ophir had a problem like this recently.

He was designing a complicated optical setup for a unique, custom laser beam profiler. When he couldn’t find the invisible (IR) laser at first, he figured, “No problem. We’ll just use the guide laser. However, part of the design included filters which are meant only for infrared, and the visible guide laser was not passed through.

After many frustrating attempts, someone finally said, “Why don’t you just use a BeamTrack sensor?”

After all, it’s our own product!

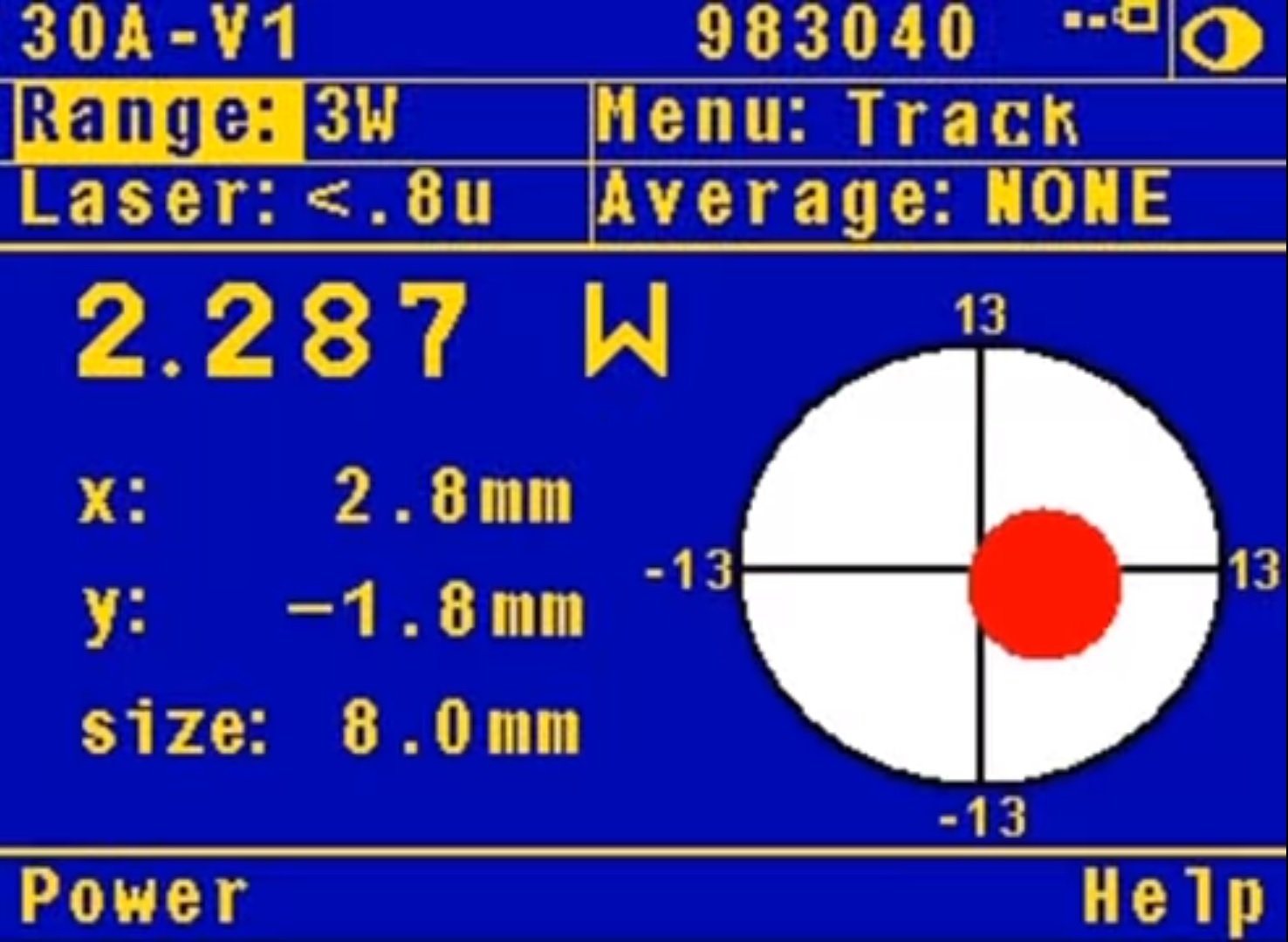

BeamTrack is a regular thermal power sensor (read: broadband with high damage threshold), that can also measure position and size. (Ophir “Quad” sensors measure power and position; “PPS” sensors measure size as well.)

So he stuck a beam track position (“quad”) sensor at different points in the optical path to try to see what went wrong.

Within minutes, he located the problem and within two hours, he had the whole unit up and running properly. (This is after spending two days of head scratching and other classical techniques.)

Lesson:

Some people use BeamTrack since they really need to track their beam’s size and position (not just power). But many more could benefit from one of these around the lab.

When the time comes, you’ll wish you had one.

Leave a Reply

Your email address will not be published. Required fields are marked *