A common complaint from laser power / energy sensor users is that measurements from one type of sensor don’t agree with those from a different type of sensor. This is often due to the fact that the two different sensors have different apertures.

It is not enough for the sensor aperture to be larger than the beam size. In other words, “big enough” is not always big enough. Size does matter.

Size does matter

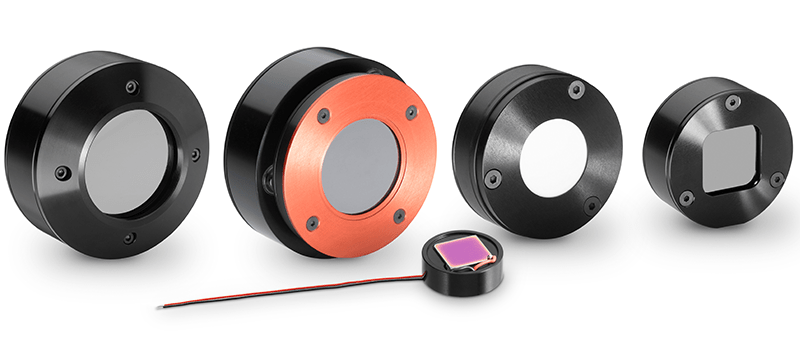

To understand this, we need to remember that laser beams rarely have sharp edges. They have guassian and other distributions. These distributions are generally characterized by long, low intensity wings that extend well beyond the nominal (D4s or 1/e2) beam width. In fact, a Gaussian beam will only contain ~86% of its total power within its nominal beam diameter.

For other beam profiles the percentage can be even lower. Therefore it is not correct to measure a 14 mm diameter beam with a 16 mm diameter sensor, no matter how well the beam is centered. At best, this sensor will measure less than 93% of the actual power. More than 7% is in the wings that are being clipped. In order to measure 99% of the total power, the sensor will need to have an effective aperture of at least 21.2 mm and that does not take into account the extra margins needed to allow for imperfect alignment.

Now that we understand that size does matter, it becomes clear that if we measure our laser beam with 2 different sensors that both have apertures larger than the ‘beam size”, but one is big enough and the other isn’t, then the measurements will not agree.

A nice safe rule of thumb is to use an aperture that is twice the size of the laser beam. When this is not practical, use Ophir’s Laser Power Through Aperture Calculator (Gaussian Beam) to know where you stand.

Leave a Reply

Your email address will not be published. Required fields are marked *