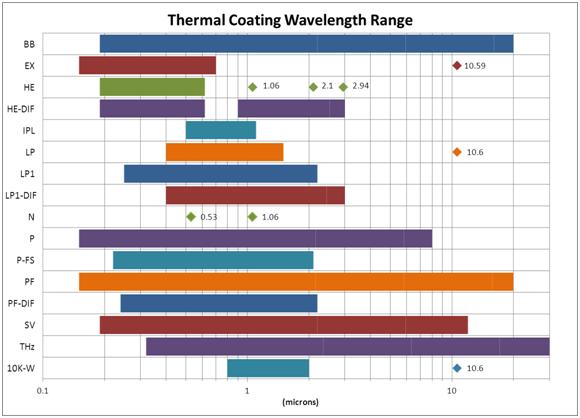

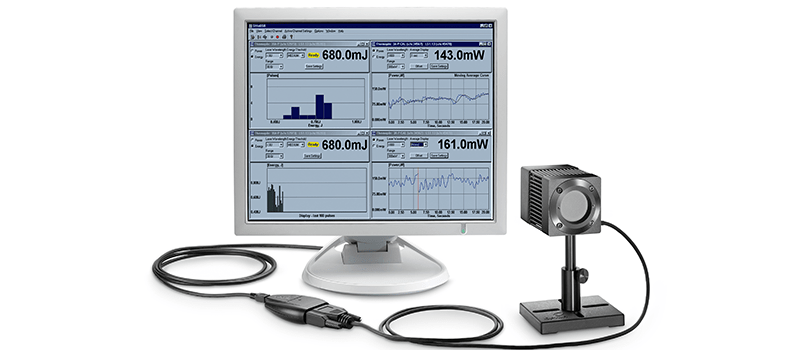

Thermal laser power sensors have various coatings used to absorb the laser heat. Each coating has its own absorption per wavelength graph which means that each coating also has its own range of calibrated wavelengths.

I decided that it’s time to make things a little less confusing, so I put together a graph (one of my favorite pastimes):

Ophir Thermal Laser Wavelength Chart

As you can see, there is no shortage of coating choices.

You might also notice that there is a lot of overlap among the different sensor coatings. That’s because there are other differences between the coatings that don’t necessarily affect their calibrated wavelength range.

For instance, some are intended for long pulses (LP), some for very short pulses (P). Some have a higher calibration accuracy than others. Really, I could write several blog posts on this, which is why I must stay on topic. So for now, we’re only talking about the coatings as they relate to wavelength.

So, conclusions anyone?

If someone asks you what wavelengths can be measured with a thermal power sensor, you can confidently respond that Ophir offers products that cover all wavelengths between 150 nm and 30 μm.

More importantly, if your laser is 4 μm, you can easily spot that you’ll need either a BB, P, PF, SV, or THz coating.

Your work isn’t done yet, but now you have a head start into finding the best thermal sensor to meet your specific laser needs. (Need help? Try our laser sensor finder.)

You might also like to read:

How to Measure Different Wavelengths with a Laser Power Meter

Leave a Reply

Your email address will not be published. Required fields are marked *