Imagine you have a KW laser in use.

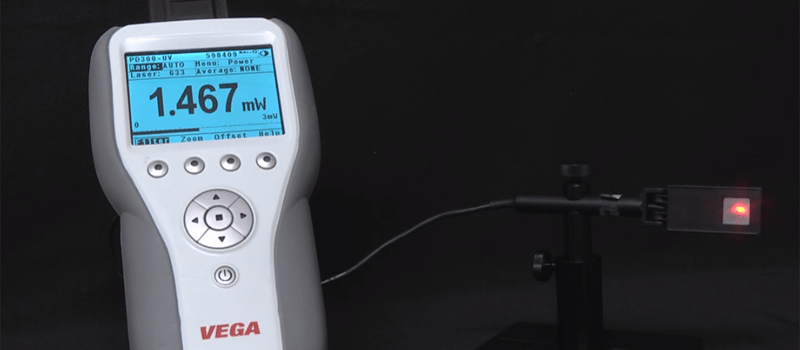

You of course realize the importance of measuring its power in order to keep your process running smoothly.

However, the water cooling that such sensors need (they need water cooling, don’t they?) is causing you headaches – maybe disconnecting and reconnecting your plumbing is an invitation to leak problems, or maybe water is an unwelcome substance anywhere near your particular process.

You can say goodbye to those headaches. Here are 3 Ophir solutions for measuring KW lasers without needing to call the plumber:

Here are 3 Ophir solutions for measuring KW lasers without needing to call the plumber:

1. The fan-cooled FL1100A-BB-65 can handle 1100W continuously, cooled by its high-power fan.

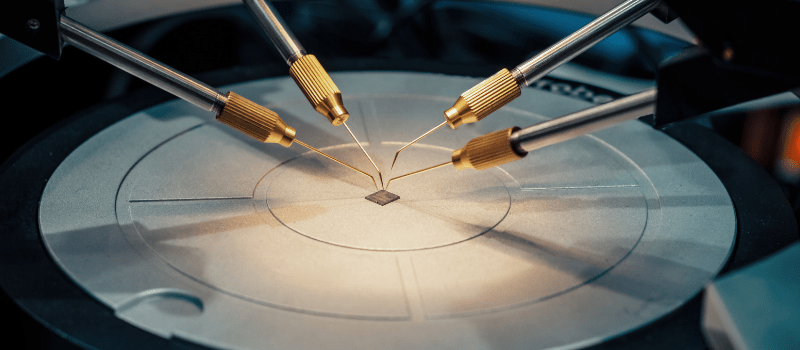

2. Keeping in mind that power is energy over time, and that it is the total energy absorbed over time that causes a sensor to heat up, it should be possible to expose a sensor to “too high” power but only for a short time, and have the sensor survive the experience.

The sensor can treat that short exposure as if it were just one long “single shot” pulse, and measure the energy of that pulse. Divide the energy by the (known) pulse width, and that gives the power during the pulse. (It can’t measure power directly this way, though, since a thermal sensor’s response time to power is itself a few seconds).

For example, the moderate-power L40(150)A has a 4KJ energy scale (as do several other such sensors); to measure power of an 8KW beam, we can fire the laser for 0.5 seconds with the sensor in energy mode, and we’ll measure 4KJ energy in the “pulse”. Dividing that by 0.5 seconds gives the 8KW beam power. Of course we then need to wait for the sensor to cool before repeating, but in some applications that may be perfectly OK.

3. If you have the StarBright meter, you can do the above automatically, with any power sensor, using StarBright’s “Pulsed Power” function.

Leave a Reply

Your email address will not be published. Required fields are marked *