Additive manufacturing, commonly known as 3D printing, has transformed the manufacturing industry, enabling the creation of complex and customized objects with unprecedented precision. One critical aspect of additive manufacturing is the monitoring and control of the printing process within the chamber.

While precision and efficiency are paramount, having user-friendly tools is essential for technicians in the field.

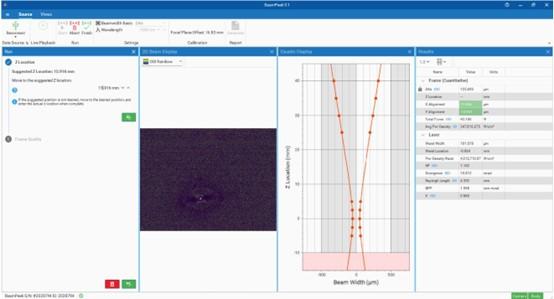

We are proud to unveil our simplified laser analysis BeamPeek Software, specifically designed to cater to the needs of technicians operating in additive manufacturing chambers. This user-friendly software offers a streamlined interface and intuitive features, empowering technicians to easily optimize the printing process using our BeamPeek Device.

In this article , we will delve into BeamPeek Software’s key features with particular emphasis on how it simplifies laser analysis while remaining user friendly.

The Need for Laser Analysis in Additive Manufacturing

Laser analysis is needed in additive manufacturing to enable quality control, optimize the manufacturing process, and detect defects. Simply put, laser analysis helps manufacturers achieve consistent and reliable results, enhance product quality, and advance the capabilities of additive manufacturing technologies.

BeamPeek harnesses the power of laser analysis to provide comprehensive monitoring and control capabilities for lasers within the additive manufacturing chamber. Laser analysis enabled by our software allows for precise monitoring of critical processes.

Key Features and Measurement Parameters

BeamPeek’s software features were designed to provide manufacturers with essential insights and analysis. including:

- Waist Location Wizard: A quick analysis of beam parameters, determining the approximate waist width and location with only 3 measurement points. BeamPeak uses this information to guide technicians in collecting points in the most critical locations, making it possible to obtain the crucial information in the record time, without sacrificing accuracy.

- 2D Beam Display: Visualizing the laser beam in two dimensions, this feature provides a comprehensive view of its shape, size, and intensity distribution. This information aids in identifying any irregularities or aberrations that may affect print quality.

- Caustic Display: This feature allows users to observe the beam’s transformation through the optical system, enabling a deeper understanding of its characteristics and performance.

- Report Generation and Selection: Our software streamlines the reporting process by automatically generating PDF reports that summarize the measured parameters and analysis results.

- Measurement Capabilities: Our laser analysis software offers a range of measurements to aid in optimization and quality control like Waist Width, Waist Location, Power Density, M2, Ellipticity, BPP, and Rayleigh Length.

- Licensing Options and Enhanced Capabilities: Our software allows customers to choose between BeamGage Professional and BeamPeek software, offering the most suitable solution for their needs. With enhanced capabilities and advanced algorithms, the software offers a range of cutting-edge features that enable manufacturers to achieve exceptional results.

Simplicity without Compromise:

Recognizing the importance of clear and concise data presentation, BeamPeek offers easy-to-understand visualizations of beam characteristics. The 2D beam display provides technicians with a comprehensive view of the beam’s shape, size, and intensity distribution, facilitating quick identification of any irregularities or deviations. The caustic display feature enables technicians to observe the beam’s behaviour as it passes through the optical system, aiding in in-depth analysis and troubleshooting.

- – In the rapidly evolving world of additive manufacturing, our user-friendly BeamPeeK laser analysis software offers technicians a powerful tool for optimizing the printing process. With its simplified interface, intuitive features, essential measurements, and streamlined report generation, our software enhances efficiency and productivity. By prioritizing user-friendliness, we empower technicians to make informed decisions, troubleshoot effectively, and achieve exceptional results in additive manufacturing.

Unlock the full potential of your additive manufacturing operations. Call us today to integrate BeamPeak’s software.

Leave a Reply

Your email address will not be published. Required fields are marked *