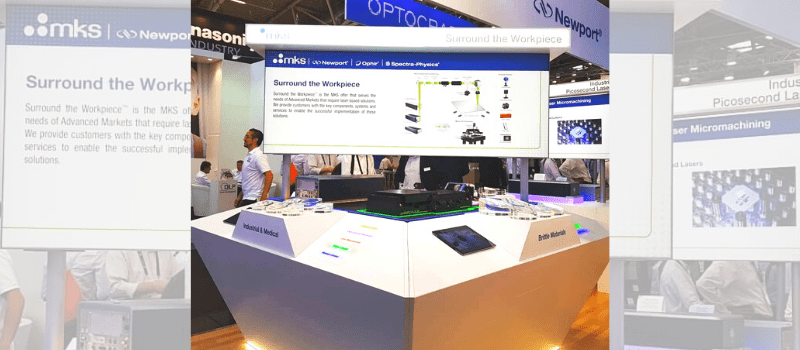

Axtra3D was founded in 2021 with the ambitious goal to shake up the additive manufacturing industry. Only one year later, the company introduced its Hybrid PhotoSynthesis Technology (HPS), which is indeed transforming the market. HPS is the first coaxial system to allow the user to print fine features very fast and with superior surface finishing.

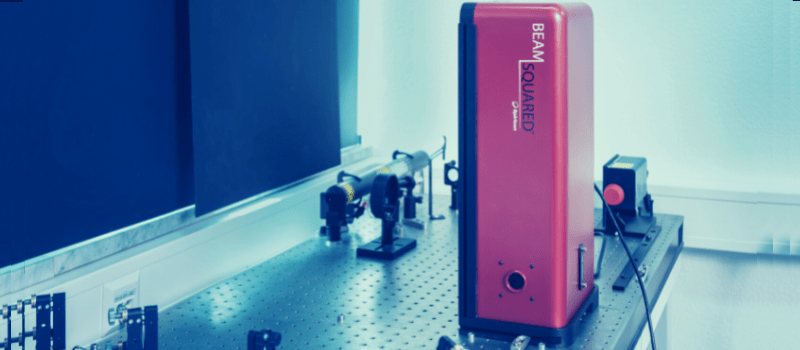

The innovation is based on a photopolymerization process with two light sources: a digital projector combined with a solid-state laser.

Key to the HPS technology is perfect synchronization of the laser beam with the light.

In the following case study, you’ll find out how the company achieves the ideal fit and relies on Ophir® measurement devices during the whole product cycle.

Leave a Reply

Your email address will not be published. Required fields are marked *