There are many challenges in the development and production of laser systems for medical applications – and the safety requirements are significant. It’s no wonder that medical technology manufacturers choose their suppliers very carefully.

WaveLight GmbH, a subsidiary of Alcon and market leader in refractive surgery, successfully uses products from MKS Instruments in the development, production and maintenance of its high-quality laser systems.

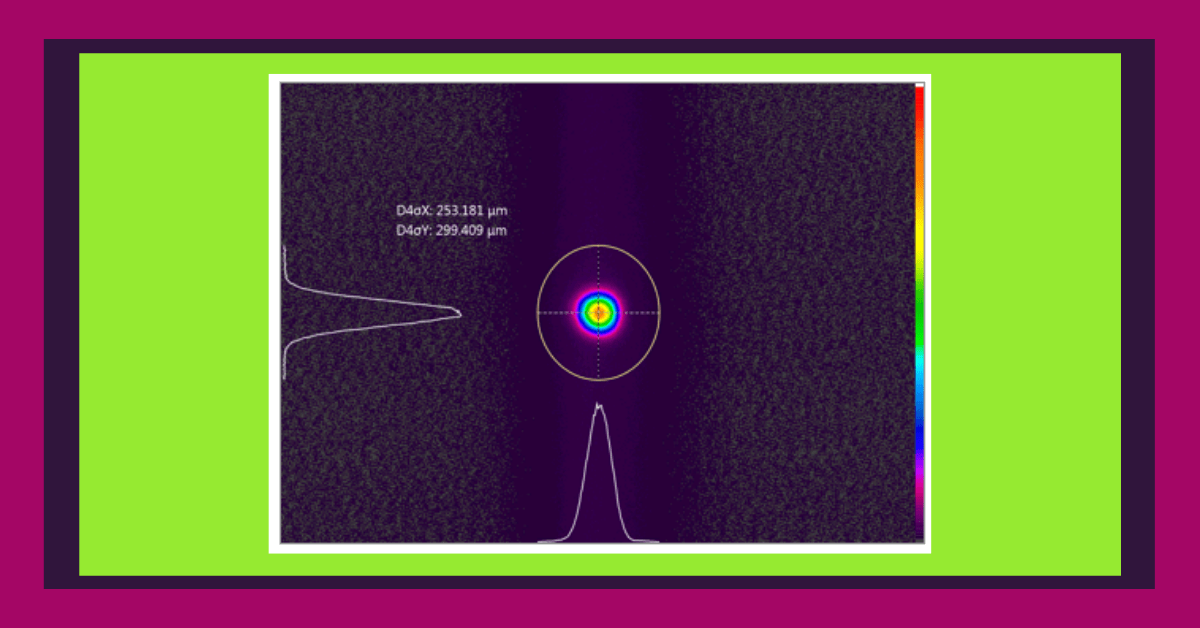

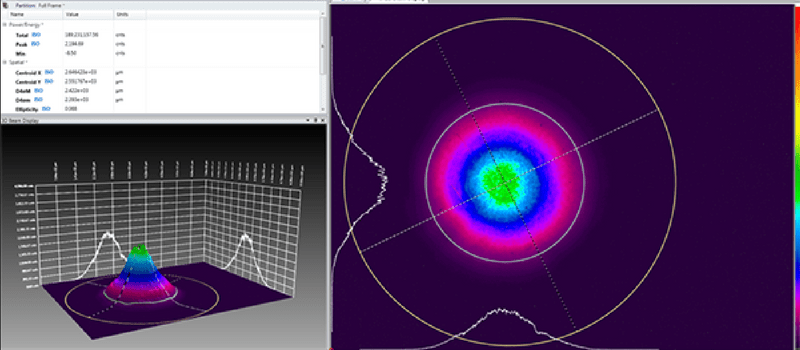

Spectra-Physics laser sources have been integrated into WaveLight® FS200 femtosecond laser systems for over ten years, and Ophir solutions for measuring laser power and energy, as well as for laser beam analysis, are employed throughout the process from development to maintenance. Millions of patients benefit from this collaboration.

Refractive surgery requires the very highest quality

The number of people with ametropia is on the rise, and many of them feel so restricted by it that they decide to have their vision corrected by laser treatment.

Refractive surgery is thus becoming more and more important worldwide. One of the foremost companies in terms of modern diagnostic and surgical technologies for correcting refractive errors using eye lasers is

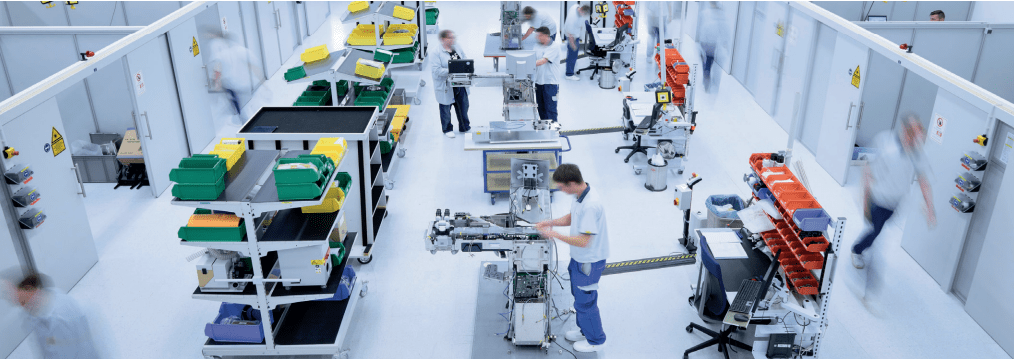

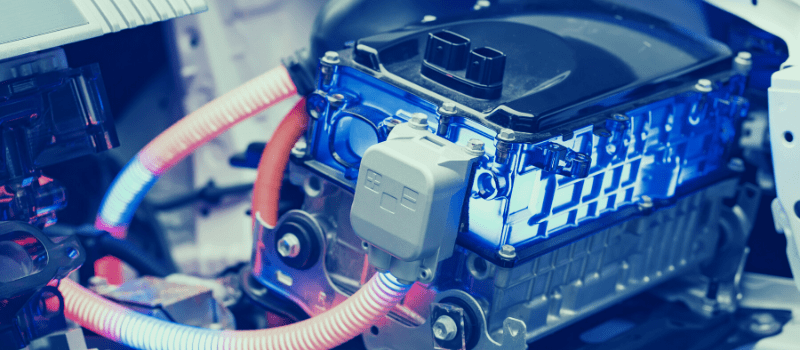

WaveLight GmbH. A subsidiary of Alcon, in turn one of the world’s leading ophthalmology companies, WaveLight develops and produces high-quality laser and diagnostic systems at three locations in Germany. Since the launch of the WaveLight® Refractive Suite, which consists of the WaveLight® FS200 femtosecond laser and the WaveLight® EX500 excimer laser, several thousand of these systems have been put into operation worldwide, and millions of patients have been operated on with the Refractive Suite.

This resounding vote of confidence is no coincidence: WaveLight attaches great importance to precision and quality in both development and production. Laser sources are tested and selected accordingly, so the requirements for the laser measurement technology are correspondingly high.

Read full article here

Leave a Reply

Your email address will not be published. Required fields are marked *