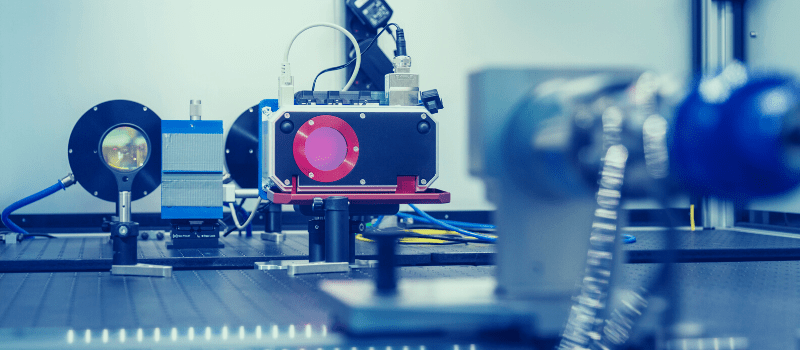

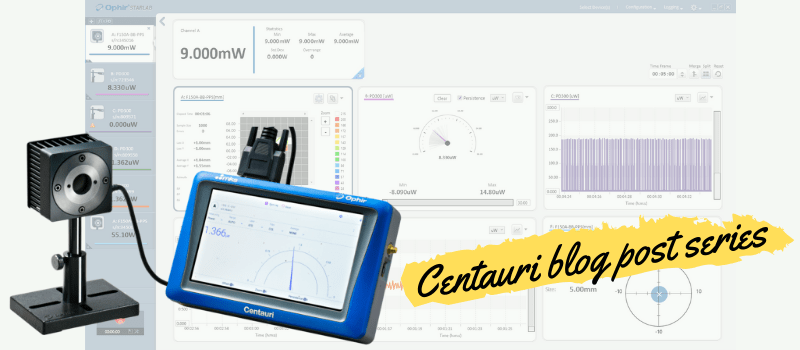

There are many ways to measure laser output: You can use a photodiode, thermopile, or pyroelectric sensor. This post will discuss how a thermopile is used to measure your laser (basics only) and what types of lasers it is suitable for.

Measurement Mechanism

Thermopiles measure lasers indirectly, by measuring how much the thermal disk heated up from the incident laser power. The heat flow measurement is in direct proportion to the laser power, and this is confirmed by careful calibration.

Types of Lasers

Thermal sensors are best for measuring medium to high power lasers:

- Powers from microwatts to tens of kW

- Broad wavelength range, usually from UV to mid or far IR (e.g., 10.6 micron wavelength)

- Dynamic range of an individual sensor is about 3 orders of magnitude

Strengths

Thermopile sensors can handle the most power of any type, by far. They also have low angle and wavelength dependence, making it easier to measure some types of lasers accurately.

Other Considerations

Thermopile sensors have relatively slow response time. It is usually between a fraction of a second (at low powers) and several seconds, increasing with increasing power.

Read this post for more information on how thermopiles work and what measures you can take to improve your accuracy.

Leave a Reply

Your email address will not be published. Required fields are marked *