In many laser measurement applications, the beam size can be controlled.

In such cases, how large should you make your beam? How much of the sensor’s aperture should the beam ideally fill?

We’re going to need to balance 2 conflicting needs:

On the one hand, you want a…

Larger beam

Making the beam larger makes the power density smaller – and that keeps you farther away from the sensor’s damage threshold.

Also, it minimizes the effect of any small local non uniformities across the absorber surface.

On the other hand, you want a…

Smaller beam

…in order to avoid a different problem, which is this:

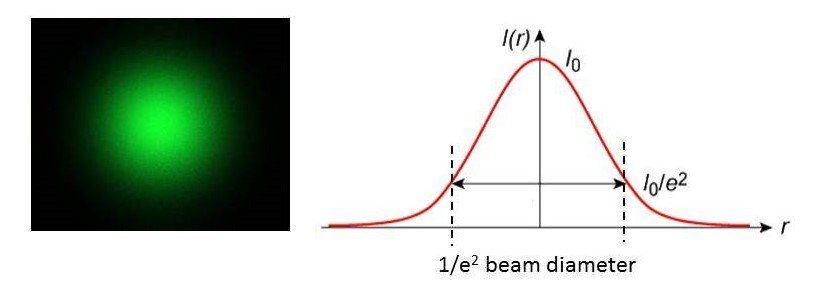

Consider a Gaussian profile:

Note that the beam edges are not marked by a clean border – beyond the 1/e2 beam diameter, there is still quite a bit of power in the more-or-less invisible “tails”.

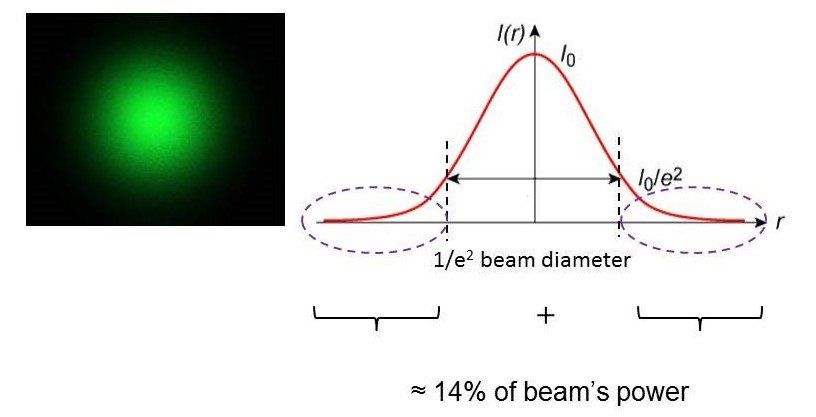

Because of this, if for example your aperture is just exactly the (1/e2) beam diameter, you’re actually cutting off 14% of your beam – a large measurement error, and one that you likely won’t be aware of.

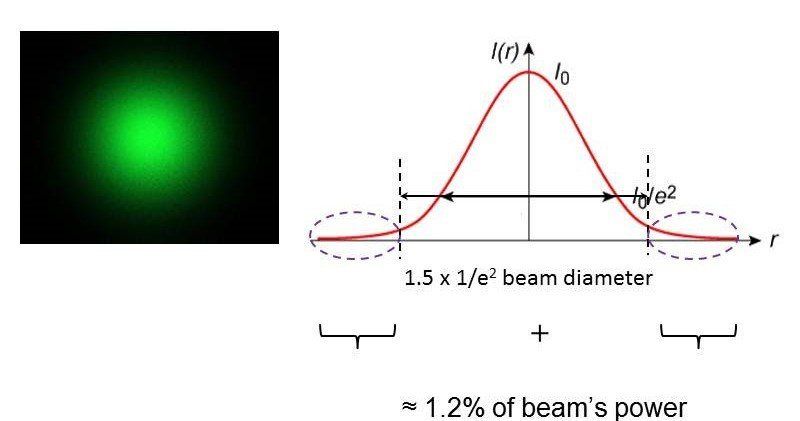

On the other hand, if your aperture is 1.5 x (1/e2) beam diameter, then you’ll still be chopping off part of the beam, but this time it’s only 1.2%.

We call this effect “Vignetting”.

The best practice approach is to find a healthy balance between “not too small” and “not too large”.

When we calibrate sensors here in the Ophir factory, we adjust the beam size so that it fills ≈ ⅓ of the sensor’s aperture or less (as long as that still leaves us safely below the damage threshold)

Our Recommendation:

To measure with the stated accuracy of a given sensor, the beam diameter should not exceed 2/3 of the sensor aperture’s diameter.

Leave a Reply

Your email address will not be published. Required fields are marked *