Medical devices have to be accurate.

Often, there are regulations about how accurate the medical laser system must be. Whether there are regulations or not, the main concern is the health of the patient.

We must be absolutely sure the laser and system are calibrated and accurate, so they will heal the patients, instead of causing an unfortunate accident.

As you design the laser aspect of your medical device, there are a few things you should think about to make sure the laser measurement sensor will be accurate and will continue to remain as accurate as it should be.

Before you do anything else, establish a baseline

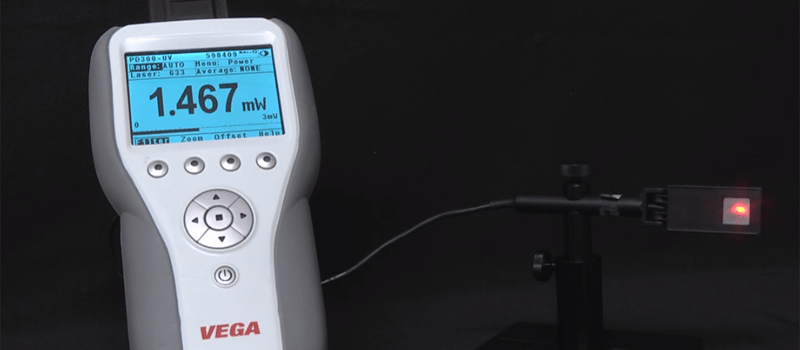

Before you integrate anything, you’re going to want to measure the laser with a prototype or similar standalone sensor to be sure your assumptions about your laser are correct.

For instance, is the power or energy in the ballpark you expected?

Is the power noisier than you thought? Is there a slow drift in power level (increasing or decreasing)?

Noise and drift are stability issues that may or may not be concerns given your particular medical application. Regardless, it’s important to make sure you know what your laser output truly looks like. After integration you can look at the readings and determine whether the laser remained the same or is suddenly acting differently than before.

For example, let’s assume that the amount of noise you measure is acceptable based on the medical research of your laser-based application. You’re okay with the noise, but you need a way to measure it easily. You might want to integrate averaging directly into your automatic laser measurement.

If it’s a slower drift in noise level, averaging might not be practical. You might want to take a few measurements at intervals, or perhaps not. In this case, it really depends on the nature of your application. Will your laser be on for a long amount of time, so the drift will settle by the time you use it? After answering these question you can decide how many times to take readings and how best to measure the aspect of the laser that is important to you.

Bottom line: Measure the laser before integration to avoid unpleasant surprises when it’s “too late.”

What else can you do to make sure your laser system is designed to be as accurate as possible?

It goes without saying that you’ll want to be sure you’re using the best sensor for the job. Choose a sensor based on your laser parameters and the nature of your application. Let us know if you need help finding the right sensor.

Here are a couple of other pointers to help ensure you’re getting the highest accuracy possible in your situation:

Aperture size and laser beam size

Your beam should fill about one third to two thirds of the sensor aperture for maximal accuracy.

In other words, choose a sensor that’s 1.5 to 3 times as large (by diameter) as the beam.

If the aperture is smaller than this, it could lead to vignetting, an optical principle that basically amounts to cutting off a bit of the beam.

(If you’re curious about this, the quick explanation is that a 5 mm laser beam is not really exactly 5 mm. Rather, the edges slope off very gradually until they are indistinguishable from the ambient light noise level. So if you use a 5 mm aperture for a “5 mm laser,” the low (but not trivial) levels of light past 5 mm will be cut off and not measured. This results in an incorrect power reading. Find out exactly how much power fits into the aperture with this calculator.)

Ambient Temperature

Another design consideration is the ambient temperature where the sensor will be housed.

The absolute temperature should match the operating temperature spec. (We usually recommend 15‑35 °C.) Using a sensor above the recommended ambient temperature will often result in a lower maximum power that can be used. So if you anticipate a high ambient temperature, let us know and we’ll help you find the appropriate sensor based on the laser power and ambient temperature.

The ambient temperature will not affect the reading’s accuracy, however, unless it gets close the maximum of the allowed range.

On the other hand, if the ambient temperature is unstable, this can (and probably will) affect the reading, especially if you’re using a thermal sensor. Thermal sensors measure the laser by detecting the resulting heat flow. If there is a change in the ambient temperature, this will cause its own heat flow and induce a reading as well. The result here is an incorrect laser measurement, which nobody wants.

Bottom line: We haven’t seen temperature to be a big concern with our medical customers, but if you think it could be an issue in your system, please bring it up so we can find you an appropriate solution.

Annual Recalibration

At Ophir we calibrate all our sensors, traceable to NIST masters. We usually offer an absolute accuracy of ±3%, but this actually varies by type of sensor, type of calibration, etc. (For situations that require better accuracy, we can achieve this by our “special calibration” service.)

Whatever the case, we find that this accuracy spec is generally good for at least a year. After that, like all materials, your sensor will begin to slowly degrade, causing a drift in the accuracy of its calibration. The environment and amount of use can have a significant effect on the speed and severity of this drift, but in any case, we cannot guarantee continued accuracy without annual recalibration.

This is easy to tell customers that buy one or two units, but you’re an OEM integrating a laser sensor into your system. How do you recalibrate sensors that are inside units you already sold?

This is an excellent question, and ultimately you’ll have to decide for yourself what solution is best for you.

What I can tell you is what some of our customers already do.

In most cases, the laser medical device itself requires a technician to recalibrate it periodically. Attention to the laser power sensor should be a part of this scheduled upkeep.

How you recalibrated is again, ultimately your decision.

- You can send it in for recalibration, which is actually quite fast (if you happen to be located in the US).

- Another option is to have a few spare calibrated sensors to substitute for your customers in these cases.

Bottom line: We understand that annual recalibration is not going to be easy. But it is very important for maintaining the accuracy you worked so hard to achieve in the first place. Don’t overlook the long-term care of your equipment.

Let’s wrap it up

You want (or need) your laser measurement to be accurate.

- Your first step is to establish a baseline of your laser performance and choose the right sensor for the job.

- Next, you’ll want to pay attention to aperture size and temperature considerations, along with any issue that are particular to your specific application.

- Finally don’t forget to talk to your customers about annual recalibration.

Follow these steps and your customers will thank you for their consistent and accurate laser measurement.

Contact us to integrate laser measurement into your own medical device.

Flickr creative commons image courtesy of Jacob Davies

Leave a Reply

Your email address will not be published. Required fields are marked *