Update (January 2015): This power sensor has been improved to measure up to 120 kW of continuous laser power. Read on to find out why we developed this sensor and how it works.

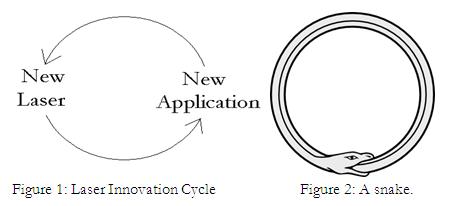

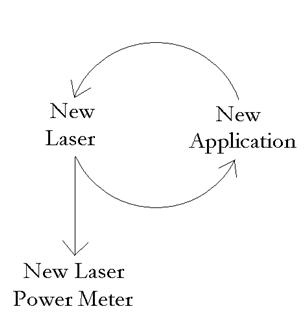

In the last few decades, lasers have been applied to more processes than just about any other technology. As new applications are considered, new lasers need to be developed, which in turn enable even more applications.

Measurement & Control

Ever wonder why these two words seem to go hand-in-hand? Sure, if you want to have a feedback mechanism, for example, it wouldn’t be possible without also measuring the laser. But I think there’s a deeper connection. Accurate measurement of the laser is a necessary prerequisite for control. If you don’t know exactly how much power it outputs to begin with, fine control of the laser power will be meaningless.

Okay, so lasers require laser power sensors. How does this fit into our cycle model? As laser continue to push the envelope in every direction, companies like Ophir race to keep up. If there’s a 100 kW laser being used, we want you to be able to measure it. Easily.

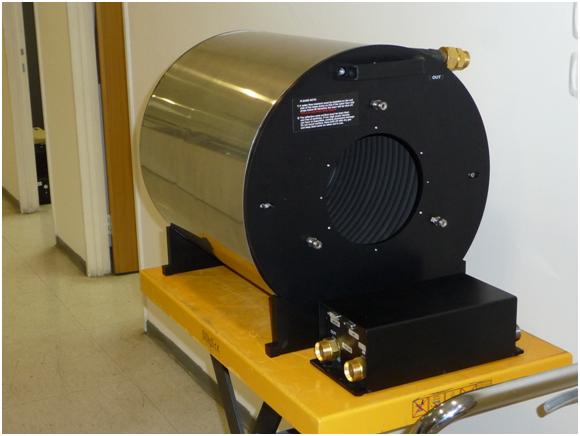

That’s why the latest addition to Ophir’s OEM sensor line can measure up to 100 kW directly.

Ease of Measurement

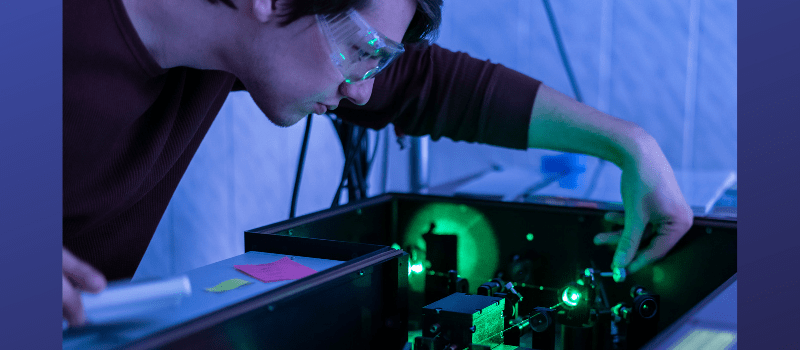

One of the issues that comes up with laser measurement, especially at such high powers is: How can you put any sensor in front of a laser that’s specifically designed to pulverize steel?

Clearly, this obstacle needs to be addressed.

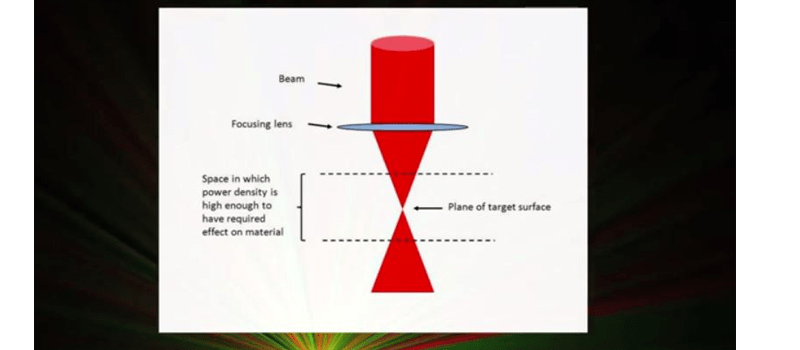

One option is to take a power meter designed for 10 or 20 kW and use optics to tone down the laser beam. Maybe you can use a beam splitter and some attenuation. Maybe a beam expander to reduce the power density. But at that point are you really measuring the same laser that you’ll use in your application? It’s better than nothing, but the less you change your laser before measuring it, the better your measurement will represent the laser.

That’s why I want to stress: When I said you can measure 100 kW directly, I meant it.

You don’t need attenuating filters or a beam splitter. You don’t even need a beam dump, as this sensor absorbs 99% or your beam.

This sounds too good to be true. You might be asking yourself…

How does it work?

The laser beam is measured at a point (after focus) when it has expanded to at least 100 mm. When it enters the cavity of the sensor, it is spread out along the inner wall by a reflecting cone to reduce the power density even further.

Find out more

There’s much more I could tell you about this sensor, but I’ll direct your attention instead to this press release , which should fill you in on the details.

Any other questions, feel free to contact one of our representatives.

Leave a Reply

Your email address will not be published. Required fields are marked *