Production systems for the luxury food and tobacco industries are complex,

achieve very high throughput rates and often run 24/7. In order to ensure the products’ high quality, the Körber Business Area Technologies counts on seamless monitoring of the entire manufacturing process in the plant.

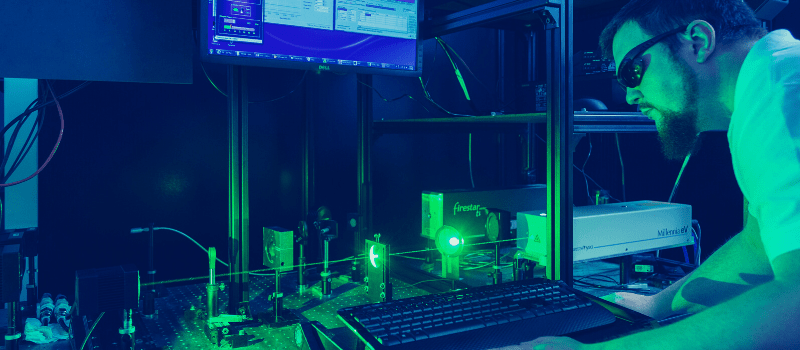

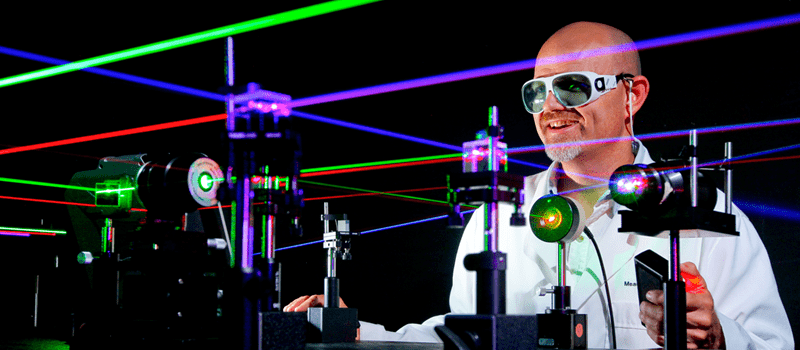

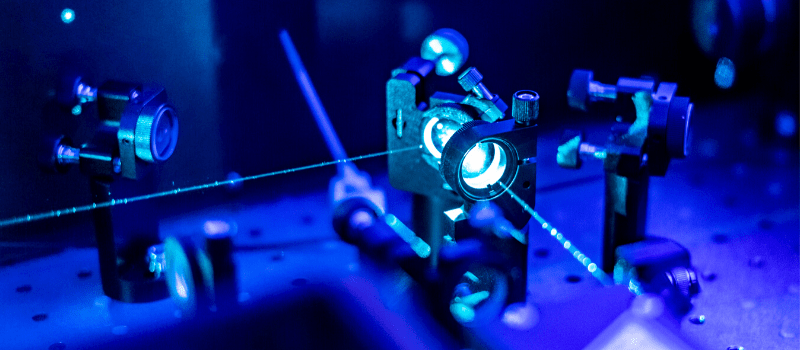

This expectation also applies to the laser-based perforation systems that the company integrates into its lines.

Based on Körber’s specifications, MKS developed a customized Ophir® OEM

sensor to measure the laser power, which can be integrated directly into the equipment.

For maintenance tasks, the plant manufacturer also uses and recommends another Ophir OEM quad sensor to measure the position and power of the laser beam.

Read full case study here

Leave a Reply

Your email address will not be published. Required fields are marked *