In laser materials processing applications, more and more customers are demanding from manufacturers to use accurate laser measurement equipment to monitor the power output of their laser systems.

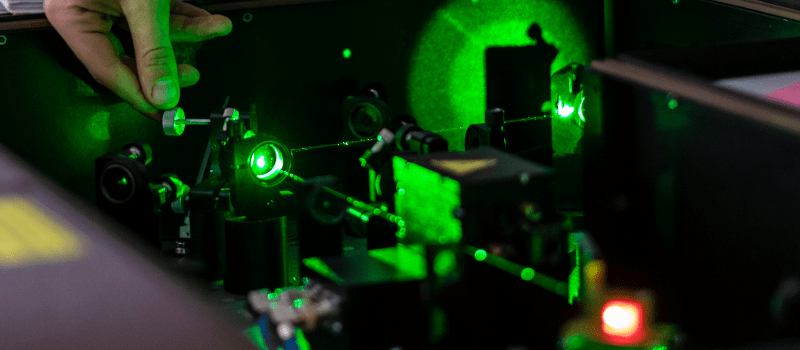

For example, Ophir was recently contacted by a company that manufactures jet engine blades and uses lasers to mark serial numbers on each blade – an industry requirement (for the purpose of accident investigation in the event of an engine-related crash, for example). In a typical laser marking system, a laser beam propagates through beam shaping optics and is then scanned by a computer-controlled scanner through a focusing lens onto the workpiece.

In order to achieve precise readable serial numbers, the laser marking system’s power output has to be within specification; a power output which is too low would result in unreadable serial numbers. The engine blade manufacturer had been relying solely on the marking machine’s panel settings to set the correct output power. A major customer, however, pointed out that internal components of the marking machine (such as the laser itself or the delivery optics) may degrade or lose alignment over time, and the actual laser power reaching the workpiece can be lower than suggested by the instrument setting. As a result, blades may be produced with unreadable serial numbers, leading to extra cost and delays in shipments because such blades would have to be re-worked or scrapped. The customer therefore insisted that the blade manufacturer incorporate an accurate laser measurement plan into the marking process which would indicate any degradation in the laser marking machine before it reaches failure level, so that preventive machine maintenance may be scheduled as necessary. Preventing the mess is, after all, far cheaper than cleaning it up!

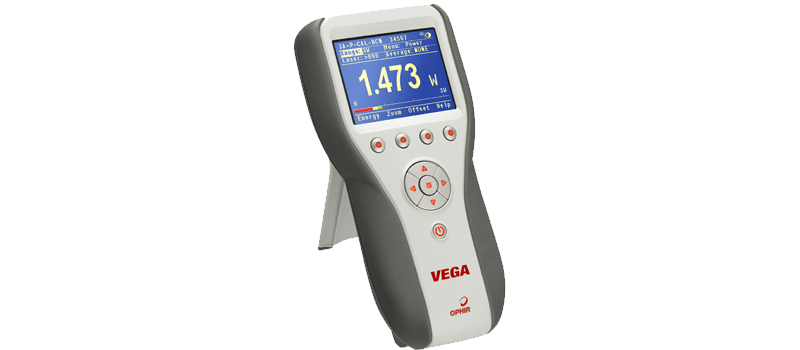

A team of Ophir engineers worked with the engine blade manufacturer to develop a regular monitoring process to keep track of the laser performance. This included developing a suitable measurement method, identifying relevant Go/No-Go limits for laser power, supplying suitable equipment for monitoring laser power, and determining the optimal monitoring schedule. The new monitoring process satisfied their customer.

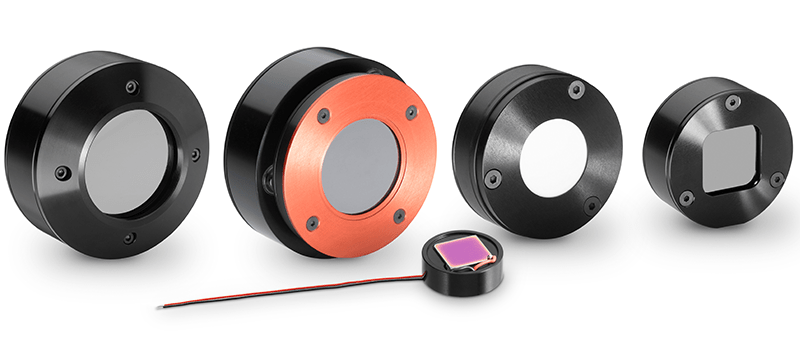

In the case above the laser measurement equipment was external to the laser marking machine, as it came “after the fact”. Today there is an increasing demand for manufacturers of laser marking and similar systems to integrate laser power and energy sensors and meters into their instruments. Ophir offer a variety of OEM solutions of laser measurement devices and software which may be integrated in host laser systems.

For further information, contact us

You might also like to read: Laser power/energy measurement today

ts great piece of information regarding Accrate Laser Measurement System and now its indespensible tool for the job.

Its great piece of information regarding Accrate laser Measurement System and now its indespensible tool for the job.