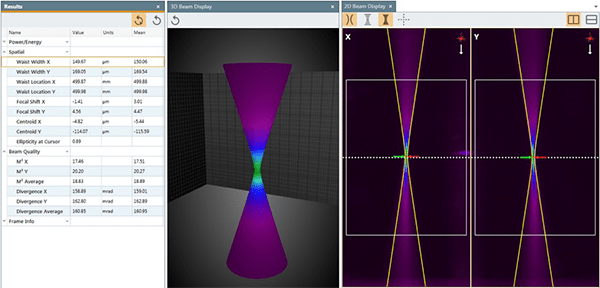

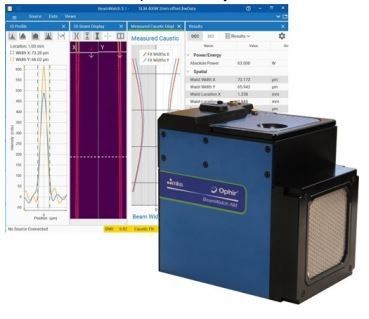

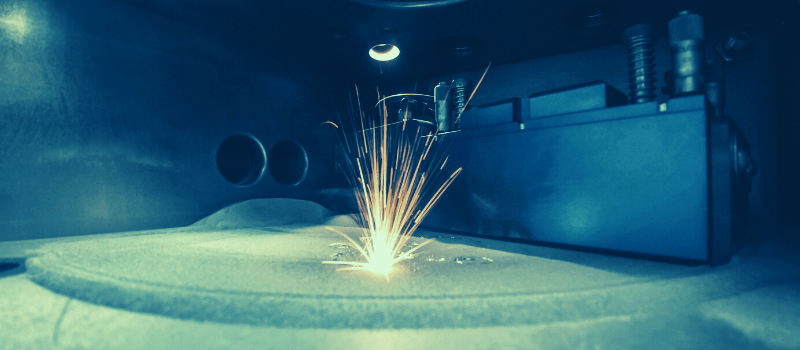

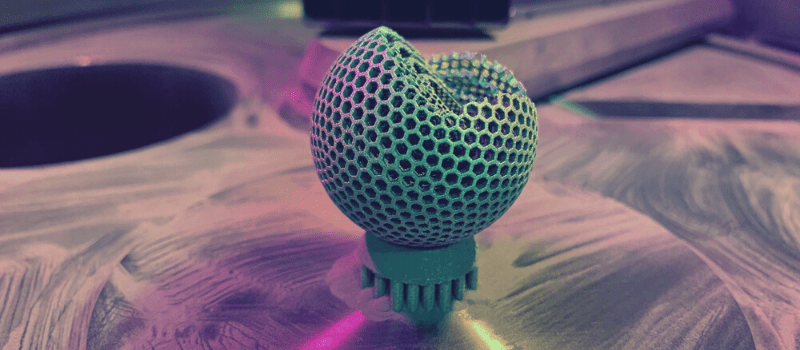

A laser profiling system can characterize and identify which variables affect product quality and waste.

But many laser users have never evaluated the quality of the beam beyond the initial delivery. This leads to frequent process adjustments to try to get back to “normal” and frantic calls to outside laser services.

Wouldn’t it be better to avoid these problems and added expenses?

Read more about how knowing and creating a process that is stable, consistent, predictable, and capable goes a long way toward generating sustainable profit, waste minimization, and end customer satisfaction in an article by Mark S. Szorik, Pacific Northwest Regional Sales Manager at Ophir. https://www.ophiropt.com/laser–measurement/knowledge-center/article/10704

Leave a Reply

Your email address will not be published. Required fields are marked *