Here’s a surprising statistic: Nine out of ten laser technicians have no idea what M² is.

Most laser beam characteristics are easy to put your finger on: laser beam width, position and divergence angle are generally known to those that work with lasers – and if not, can be learned quickly.

M² is a little more obscure and abstract.

So…What is M²?

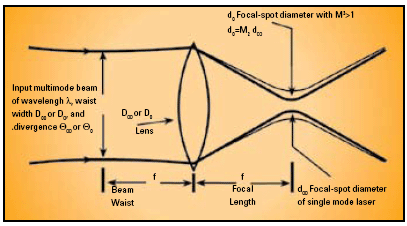

M2 takes a look at your beam caustic (the curve of the laser beam as it focuses and diverges again) and compares this to an ideal Gaussian beam caustic.

So if your beam is perfectly Gaussian, you’ll get M²= 1. For high quality beams, M² might be 1.1 or 1.2, for lower qualities you can get up to 3, 4 and even double digits for some low quality high power lasers.

How is M² measured?

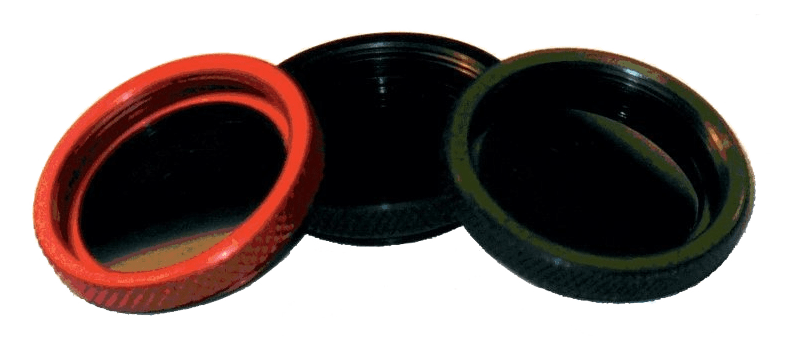

M² cannot be determined from a single beam profile measurement. The ISO/DIS 11146 requires that M² be calculated from a series of measurements. M² is measured on real beams by focusing the beam with a fixed position lens of known focal length, and then measuring the characteristics of the artificially created beam waist and divergence.

To provide an accurate calculation of M², it is essential to make at least 5 measurements in the focused beam waist region, and at least 5 measurements in the far fields, two Rayleigh ranges away from the waist area. The multiple measurements ensure that the minimum beam width is found. In addition, the multiple measurements enable a “curve fit” that improves the accuracy of the calculation by minimizing measurement error at any single point. An accurate calculation of M² is made by using the data from the multiple beam width measurements at known distances from a lens, coupled with the known characteristics of the focusing lens.

All this is to say that M² measurement can be a little complicated. Here are a few tips to help you get the most, based on some customer questions we’ve gotten recently:

M² Q&A

Q: How can I maintain high repeatability from one bench calibration to the next?

A: You should try to use consistent optical setups, enable statistics and remove outliers. (You can remove them automatically with the M2-200s software.) Also, an optical table will be useful to minimize vibrations. With the M²-200s, you should be able to achieve reproducibility of all parameters within 5%, except for beam waist location, which is ±12%.

Q: What is the optimal beam size for M² measurements?

A: The beam should be as collimated as possible with an unfocused diameter of 1-10 mm. This will allow the focused beam waist to cover at least 20×20 pixels on the camera, which yields a fair resolution.

Q: What is the optimal laser power for M² measurements?

A: Power of the laser should be on the order of milliwatts or less. If the camera saturates, add attenuation. Be careful to make sure that the focused power density is below the camera’s damage threshold.

Q: What is the noise of M² measurements?

A: It depends which beam width calculation method is used (there are several – see the Beam Width Measurement Accuracy article for more on that). The D4σ method, which is the ISO standard and default in our software, is most sensitive to noise. You can use the knife edge (90/10) technique to increase accuracy.

Q: How can I avoid smearing (where one axis is very different from the other?

A: Smearing (or blooming) is a hardware glitch that occurs when the laser light leaks through the CCD and affects the layers underneath the Silicon. This usually happens with longer wavelengths in the NIR range. Adding exposure typically minimizes this effect. (Make sure to reduce the laser power or add more attenuation when lengthening exposure time.) The M²-200s has recently been updated with a new USB camera which further minimizes this blooming phenomenon. If you are still experiencing this problem, fill out an RMA and we’ll try to get you a better camera.

I hope this will give you a jump-start on your M-Squared measurement mission. For more info. go to: https://www.ophiropt.com/laser–measurement/knowledge-center/article/8109

And If you have other questions, feel free to leave a comment!

Leave a Reply

Your email address will not be published. Required fields are marked *