The ESA Living Planet Program is designed to find out more about our changing Earth. The Earth Explorer missions are the research missions of the Living Planet Program employing satellites with new laser measurement techniques. Among these, LIDAR-based instruments represent a recent promising area for monitoring wind, aerosols or trace gas pollutants. One main challenge for any space based LIDAR is to build an efficient and robust laser source. Several technological developments are currently moving toward achieving this goal, like the lightweight high brightness thin-slab laser.

The EarthCARE (Earth Clouds, Aerosols and Radiation Explorer) mission is a joint European-Japanese mission addressing the need for a better understanding of the interactions between cloud, radiative and aerosol processes that play a role in climate regulation. Enzo Nava, Head of the Electro-optics Section at CESI, reports. “We had to produce a pre-development model for the Atmospheric LIDAR (ATLID) laser transmitter to operate. In this case, we were developing an end-pumped Nd:YAG MOPA laser system with frequency tripling to operate at 355 nm. “The laser had to operate in pulsed Q-switched mode, with a narrow bandwidth and tight frequency control”, said Nava. We selected laser diodes to pump the small rod design that were high power QCW (Quasi Continuous Wave) diode stacks with 1.2 kW peak power at 808 nm.

“Since we already had experience with Doric Lenses (Quebec, Canada), we turned to them to develop the collimation optics and to PowerPhotonic (Edinburgh, UK) for the reshaping of the high power laser diodes”. “We were already familiar with Doric microlenses since 2001 on another project, so for this project we decided to add Doric to our team with full responsibility of the Fast Axis Collimation optomechanics”.

The design called for pump diodes with a beam profile of only 6 mm by 0.5 mm. It is essential that the source is lightweight, compact and very reliable. A detailed analysis of these requirements led to the selection of a 12-bar conduction-cooled QCW diode stack with corrective phaseplates from Quantel Laser Diodes (Nuvonyx), capable of operation at 1.2 kW peak power. These are available in a 500 µm bar pitch, providing the entire pump source within an area of only 6 mm X 10 mm, as shown in Figure 1. These stacks are already used in military applications, so they are robust and well suited to space deployment.

FIGURE 1: Shows the schematic of the twelve bar stack and nomenclature (a) nominal stack geometry (b) deviations from nominal (reference) positions

However, the divergence properties of these stacks made them unsuitable for our application unless we could develop a collimation process to fit on the stacks. These were not trivial challenges, because in addition to the divergence angle variations or each diode bar, we had to contend with the small clearance between lenses (as small as tens of microns), and also contend with the distortions of the bars themselves. “Fortunately, Doric lenses has experience with this for many years”, reported Jean-Luc Neron, of Doric Lenses. “Our expertise in micro-cylindrical lenses was driven by the needs of laser diode market. As a manufacturer of the finest cylindrical micro lenses with huge stock of different lenses, in-house optical shop and team of photonics engineers, we are perfectly positioned to do “lensing” of individual laser diodes, bars or a stack of bars”. Doric Lenses Inc. has developed a procedure of making FAC lens arrays that match 3D geometry of specific laser diode bar stack. One such array is shown in FIGURE 2.

FIGURE 2: Doric Lenses FAC Microlens Array designed to compensate for diode bar stack aberrations.

With this design, Doric was able to custom insert micro cylindrical collimating lenses aligned to each diode bar with tolerance of <+/-5µm.

FIGURE 3: Stack after primary collimation

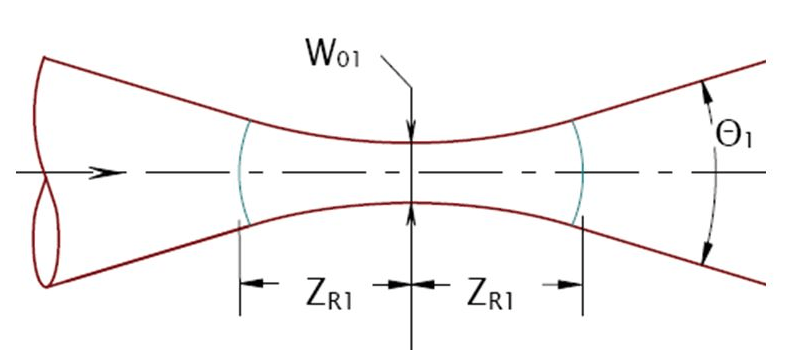

The thin slab architecture of this application places particularly stringent demands on pump beam collimation: the beams from each bar must be almost perfectly parallel, and must each have beam divergence close to the diffraction-limit. Achieving this with primary collimation alone would require lens position tolerances of <+/-0.5µm, which is beyond the capabilities of conventional machining processes. Instead, PowerPhotonic beam correction phaseplates were used to reshape the primary-collimated wavefront in order to achieve the required beam performance.

In order to align the optics and characterize the beam, a beam profiler was necessary. Laser beam profilers have been in use in Science and Industry for more than 30 years and Doric and PowerPhotonic are well-acquainted with the Ophir-Spiricon Inc. (Logan, UT) Laser Beam Analyzers. “The accuracy and reliability of the Ophir-Spiricon system made them an ideal choice to enable us to both design the correction phaseplate and then align it to the corrected diode stack in real time”, says Etienne Friedrich or PowerPhotonic. “Live visualization of the entire beam combined with accurate real-time measurement of beam divergence was essential in this application. With the Laser Beam Analyzer we are able to characterize individual bars in the stack and obtain an image for the complete stack”, as shown in Figure 4.

FIGURE 4: Beam far field image of the 12-bar diode stack after fast-axis collimation with the custom micro-cylindrical lens array. Although the collimated beam is now 30-40 times brighter than the uncollimated stack, residual aberrations from smile and tilt errors can easily be seen in this beam image of all the diodes.

When the custom designed correction phaseplate is added, the beam appears as shown in Figure 5.

FIGURE 5: Beam far field image of 12-bar diode stack after fast-axis correction with micro collimation lenses. The brightness of the resultant beam is now about 10 times brighter than that after the initial primary collimation.

In this application, enclosed power is the critical divergence factor. Primary collimation reduced the beam divergence for a 90% enclosed power beam by a factor of ~30, from 75° to 2.6°. Beam correction further reduced this by a factor of ~10 to 0.28°, effectively reducing the M2 value from between 15 to 17 to equivalent to all bars being collimated with M2=1.6 (almost the diffraction limit) and perfectly co-aligned. The result is an extremely compact high-brightness line source.

Using the combination of high output diode laser bars, a collimation and correction process, and being able to view and make adjustments in real time allowed us to design, test and deploy this very high brightness diode laser successfully. Trying to accomplish this complex process without a real-time beam profiler would have added enormous cost and time to the project.

– Article By Larry Green Etienne Friedrich

You might also like to read:

The Microscopic Structure of Air/Water Interface with Wireless Laser Connection

Worms and Lasers: A Fascinating Story

Please feel free to comment and add things you have on your list

Share this:

Leave a Reply

Your email address will not be published. Required fields are marked *