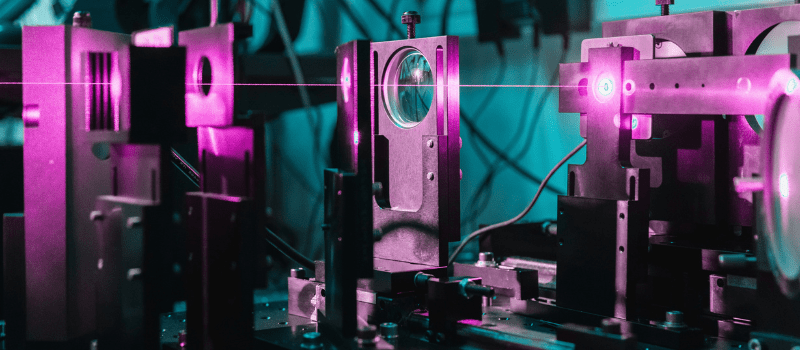

High power short pulse lasers (<100micro seconds duration) are increasing in average power and beam size and there is a need for appropriate equipment to measure these lasers over the small aperture, low average power meters typically available till now.

High power short pulse lasers cannot be measured using an ordinary surface absorber thermopile sensor. During every pulse, laser energy is deposited on the surface of the absorber during a period of time which is too short for the absorbed heat to dissipate. As a result, heat is concentrated on a very small volume of the surface, and this easily damages the sensor. Volume absorber sensors using absorbing glass or a similar material have long been used to measure short, pulsed lasers and since they absorb the energy typically in ~1mm of the material are very resistant to single shot pulses, being able to stand up to on the order of 5J/cm². However, these do not provide a complete solution. They have very poor heat conduction so they can only operate at very low power density levels, on the order of 50 W/cm². These volume absorbers are also limited in size; they are made of fragile materials like ND glass so only small diameters ~18mm are available. Thus, using volume absorbers, only small beams with low average power density levels can be measured. Other materials can be used to absorb high powers, but they are all either expensive or limited in spectral range.

Ophir has recently developed a series of sensors that address this problem. The PF series of sensors absorb a laser’s energy in a volume of a sprayed-on coating which is deposited on the sensor surface, not the typical glass or ceramic coating used to slow down heat absorption. The sprayed-on coating is less expensive than ND glass or ceramic coating, is more durable, and can be produced on substrates of any size. PF sensors are thinner, and more heat conducting and therefore can stand up to over 20 times the power density that standard volume absorbers can handle. The PF sensors allow power densities up to 3 KW/cm2 instead of the usual 50 W/cm2.

The PF sensors are also faster response than a typical volume absorber. In a standard volume absorber, the heat has to flow through a glass or ceramic layer of 1-3 mm therefore its response time is long.

Heat flows more quickly through the PF sprayed on coating which is much thinner and has better thermal characteristics. This makes the response time much shorter, as short as 1s. The PF sensors can also be made in larger sizes than the previous volume absorbers. Ophir has PF sensors with apertures up to 65mm diameter.

You might also like to read:

When to Use a Rapid Pulse Sensor?

How Can High Power Laser Measurement Sensors (1-10KW) Be Calibrated By Laser Measurement Vendors?

Leave a Reply

Your email address will not be published. Required fields are marked *