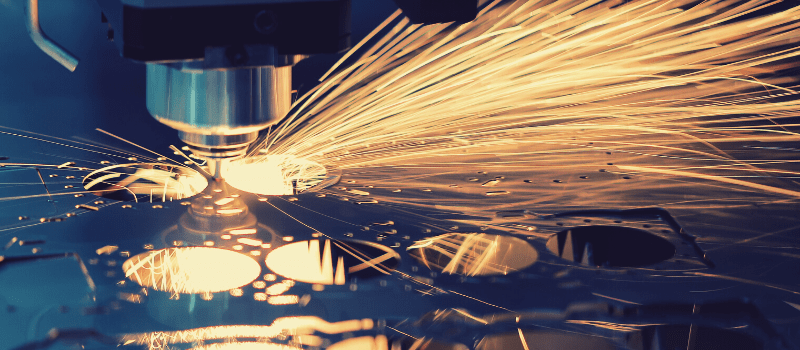

Beam profilers have many advantages over acrylic block burns for monitoring laser beam profiles. Beam profilers don’t release poisonous toxic fumes and they can measure a beams profile for longer than a few seconds. In addition, a beam profiler measures the real time distribution of a lasers power density while acrylic burns can only show the average distribution of the energy. This advantage can be crucial for monitoring lasers which operate in laser material processing work shops as demonstrated in the following example.Figures 1 & 2 show a beam profile of an industrial CO2 laser that was used to cut steel. With time there were variations in the quality of the cut. The manager had been making acrylic mode burns of all the lasers in the work shop, and the quality of the malfunctioning laser appeared to be as high as the other lasers. When beam profilers were used with this beam it was found that the mode was changing quite rapidly. During rapid changes, the acrylic mode burns would create an average of the beam which appeared quite Gaussian, whereas individual pulses were highly structured. It was discovered that these variations of time were the cause of the ragged edges cut by this laser.

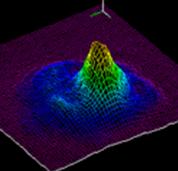

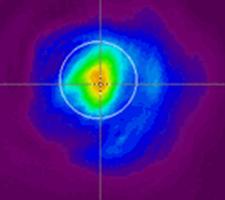

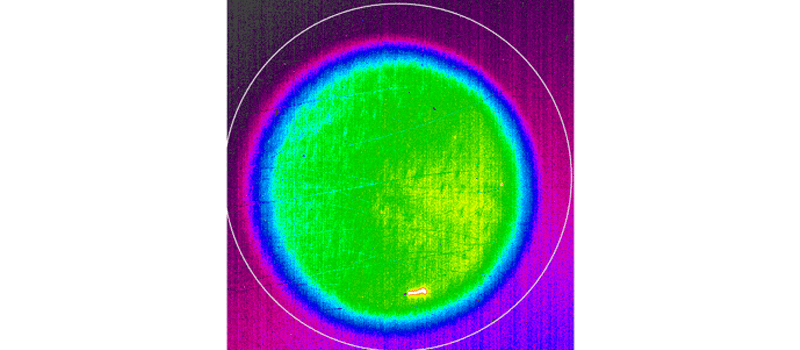

Figure 1: When defining a large region of interest, ROI, of 7.6 mm around the main lobe of the beam profile the software displayed that 78% of the lasers energy was within the ROI. 22% of the beams energy is lost outside the 7.6 mm diameter.

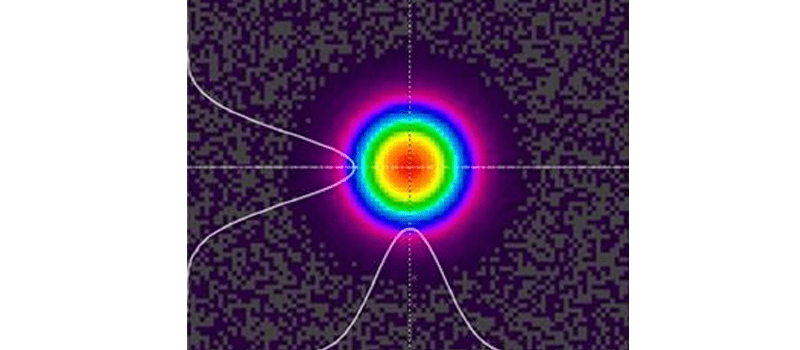

Figure 2: The same laser when taking a closer look at the main lobe. With a region of interest of 3.7 mm drawn around the main lobe the software displayed that only 33% of the energy of the beam is within the ROI. Thus, only one third of the energy is in the high intensity part that actually works the metal.

Ophir-Spiricon offers a special beam profiler for industrial CO2 lasers. It can be used to measure the lasers beam profile between laser setups or before production runs. The Mode Check is rugged, affordable, and is specially designed to be operated on a laser material processing work floor.

You might also like to read: Old Acrylic Blocks Are a Thing of the Past!! A Guest’s Perspective…

Share this:

In addition, a beam profiler measures the real time distribution of a lasers power density while acrylic burns can only show the average distribution of the energy. This advantage steel profiler can be crucial for monitoring lasers which operate in laser material processing work shops as demonstrated in the following example.