Ophir Photonics’ power and energy sensors measure lasers across various wavelengths, powers, and beam sizes, whether continuous or pulsed. This post will discuss two types of sensors that use laser-generated heat to measure laser power: calorimeters and thermopiles.

The first type operates on the principle of calorimetry, which measures the heat produced by chemical reactions or physical changes in materials. The term “calorimetry” originates from the Latin word calor (meaning “heat”) and the Greek word metron (meaning “measure”). In this method, the laser light is absorbed by the sensor and transformed into heat. By measuring the temperature increase caused by the laser heating, the optical power of the input beam can be determined.

For short-duration measurements (up to tens of seconds), the fundamental equation governing the calorimeter operation is:

Q = mCvΔT,

where Q represents the heat transferred from the laser to the measuring device, m is the mass of the heated material, Cv is the specific heat capacity (indicating the amount of heat required to change the temperature of a given mass by 1 °C), and ΔT is the temperature change experienced. Ophir’s portable sensor family, Comet, utilizes this measurement principle and operates without the need for active cooling.

For continuous calorimetric measurement, the generated heat must be dissipated. At high powers a coolant is used, usually water, in a closed-circuit chiller system. By precisely measuring the flow rate and the temperature increase of the coolant as it passes through the sensor, the optical power of the original input beam can be calculated using the following equation:

P = qvCvΔT,

where P is the laser power, qv is the coolant flow rate, and Cv is the coolant’s specific heat capacity.

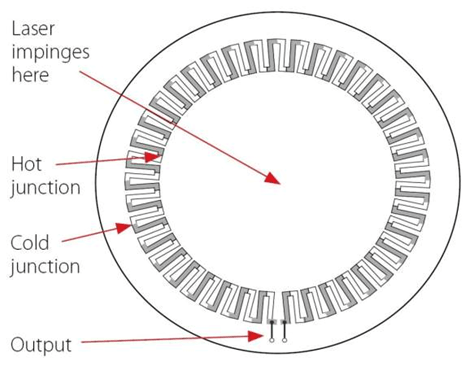

Next, we will describe how a thermopile laser power sensor works. In Figure 1 we see a typical thermopile sensor. The laser beam hits the center of the sensor where it is absorbed and converted into thermal energy. The circumference of the sensor is connected to a heat sink (air or water cooled) resulting in a radial heat flow from the center towards the edge creating a temperature gradient (hotter at the center, colder at edge). This temperature gradient depends only on the laser power and thus can be used to measure it.

This is done by placing a thermopile on the sensor disk. The thermopile uses the Seebeck effect to generate a measurable voltage proportional to the temperature difference. The arrangement of the thermopile around the laser absorption area ensures that the measurement is independent of beam size and position.

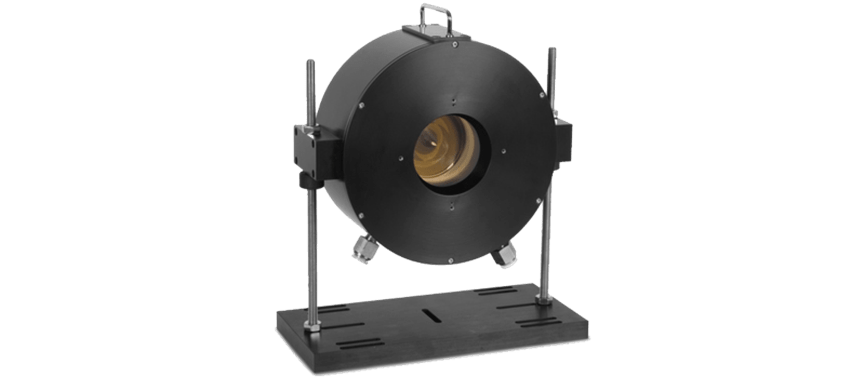

This design works well up to about 5 KW with either air or water cooling. At higher powers a gold coated reflector is used to expand the beam and reduce the power density being absorbed. This design approach is scalable up to 30 KW. Beyond that, practical considerations affect the device’s performance, making further scaling less favorable. Ophir’s largest thermopile sensor, capable of measuring up to 30 KW of laser power, is shown in Figure 2.

Now let’s focus on the advantages of either of these two measurement methods.

Thermopile power meters are more versatile than calorimeters because they can measure a wider range of power levels, from milliwatts to kilowatts. Unlike calorimeters, which require precise flow meters and temperature gauges that limit their effectiveness at lower power levels, thermopile sensors can easily handle low-power measurements.

Thermopile power meters also respond more quickly than calorimetric power meters because they generate a measurable voltage signal faster through radial heating of the disk. In contrast, calorimeters require a longer time to reach a steady-state temperature due to their larger mass. While technological improvements have sped up calorimetric devices, high-power sensors for lasers above 30 KW still have response times of tens of seconds.

Moreover, thermopile-based sensors typically require simpler cooling systems. At lower power levels, they can use passive cooling or just a fan, making them easy to set up. For higher power levels, a coolant is needed, but even then, thermopile sensors remain easier to manage than calorimetric power meters, which rely on stable coolant flow and precise temperature control for accuracy.

While thermopile sensors may appear to be the more convenient choice based on earlier considerations, calorimetric power meters have unique advantages. Their reliance on first principles makes them a more direct and potentially more precise method for measuring optical power. Additionally, they exhibit a highly linear response across different power levels. Furthermore, the direct cooling of the absorber in calorimetric meters enables them to handle much higher power levels compared to thermopile sensors. In fact, for power levels above 30 KW, most sensors are designed based on the calorimetric principle.

In summary, if your primary requirement is measuring high power levels or you’re dealing with multi kilowatt beams exceeding 30 KW, a calorimetric power meter is the ideal choice. On the other hand, if you prefer a simpler setup and require a broader power range, a thermopile sensor is likely the more practical solution. The following table summarizes the main properties of both measurement methods:

| Parameter\Type | Thermopile sensor | Calorimeter |

| Practical power range | mW-30 KW | >1 KW |

| Dynamic range | 2000:1 | 100:1 |

| Low power measurement | Possible | Limited |

| Response time | Faster | Slower |

| Precise coolant temperature and flow control required | No, only a cold-coolant reservoir needed | Yes |

| Power > 30 KW | No | Yes |

Leave a Reply

Your email address will not be published. Required fields are marked *