Since Columbia University graduate student Gordon Gould and Bell Laboratories scientists Charles Townes and Arthur Schawlow (among others) coined the term LASER in the 1950’s, applications of this technology have seemed limitless. Working with these new discoveries had to be exciting, but applying hundreds of kilowatts of laser power, like the ones being used in directed energy laser systems, wasn’t something that could even be fathomed at the time.

he application of massive amounts of laser power for neutralizing threats has proven to be a promising advancement in weapons systems in Army and Navy projects over the years. The benefits of using lasers are too numerous to ignore compared to conventional ammunition. Because they apply coherent light, there are no effects of gravity on the rounds. They travel at the speed of light and without any sound. The output can be controlled, at lethal and non-lethal doses. If there isn’t a malfunction of the system, the soldier or sailor will have unlimited ammunition. And even though the environment will affect the performance of the laser, this can be offset through optical-mechanical compensation. In addition, these benefits can often be provided in the form of a less expensive system compared to historical weapons.

Challenges with High Power Laser System Development

The development of these high-power laser systems presents a unique set of challenges, many of which are inherent to the use of high-powered lasers. Lasers that push photons of the magnitude of multiple kilowatts of average or continuous-wave power are more susceptible to thermal effects on their components, as well as increased safety concerns due to risks of eye and skin damage.

Additionally, the degradation of components can happen at a faster rate at these higher powers, more quickly resulting in less efficient performance of the system. Understanding how these effects and changes to the laser’s system affect the overall system’s performance, both under development and once the system is commissioned, is critical to ensuring successful missions.

Advancements in Beam Management

During the development of these systems, researchers often face challenges with “beam management.” When high quantities of laser light are directed at an intended target, what happens to the beam, during and after the target is destroyed, is a critical safety concern due to the potential for unintended reflection of the beam. To manage the laser light, an operator can use what is called a “beam dump,” an object usually made of a highly absorbent material that is intended to prevent the beam from damaging other objects in the vicinity of the test.

Beam dumps commonly consist of a sacrificial object such as graphite bricks, ceramic tiles, hard anodized aluminum, or even a brick wall at the back of the room. These objects are usually inexpensive and readily available. However, these types of objects usually break down quickly and become ineffective, either because they end up destroyed or turned into highly reflective glass. Sometimes they outgas, producing carcinogenic byproducts. This places unnecessary risks on research scientists.

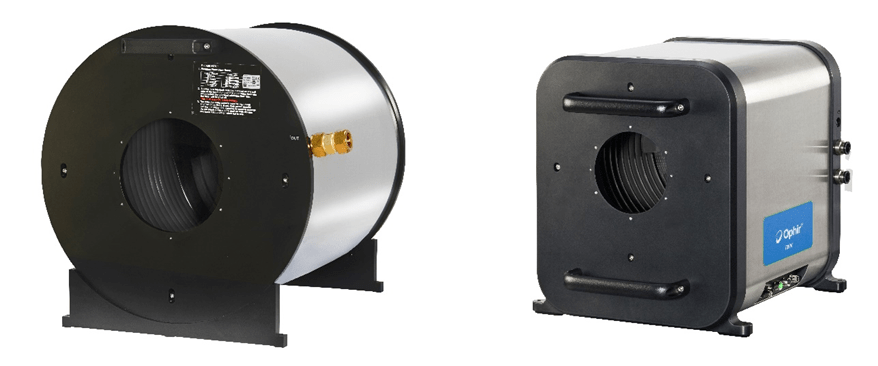

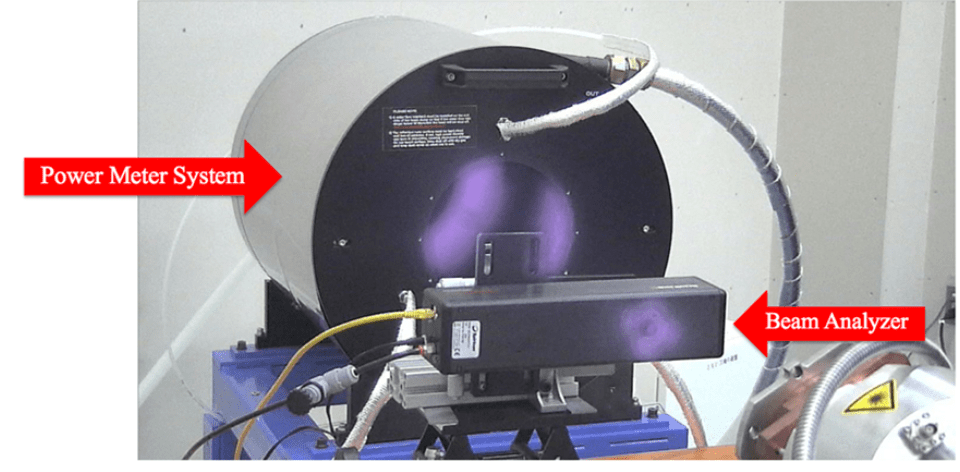

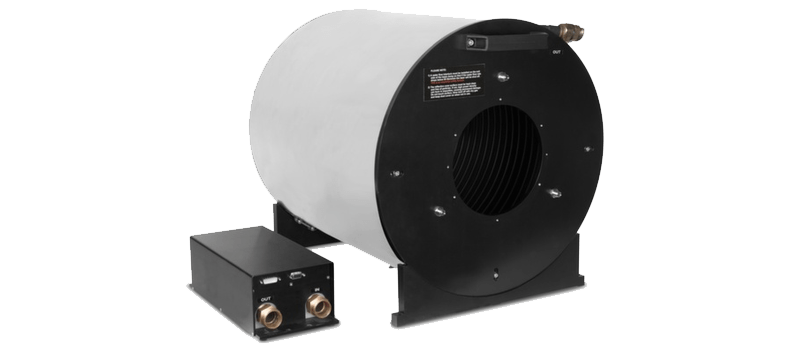

Fortunately, just as laser technology has progressed over the years, so have solutions for beam management. In 2015, Ophir released a product to effectively collect over 99% of a laser beam up to 100 kW of average or continuous-wave power. This product has evolved over the years and recently, MKS has released an Ophir extreme high power sensor for up to 150 kW. MKS has also met customer demands for beam termination and power measurement of lasers over 30kW with the recent introduction of the Ophir 70K-W product. This product provides an industrialized solution for material processing lasers increasing in power and reduces the cost for measuring and terminating lasers between 30kW and 70kW

The high power sensor consists of water-cooled channels with a proprietary coating. It delivers a high damage threshold that allows efficient removal of the heat that the laser adds to the test. The 120K-W power sensor is usually placed in close proximity to the test site in a horizontal position. The laser is fired at the target material until it has been destroyed. The 120K-W then momentarily collects the beam until the test is complete, measuring the power and dissipating the heat added by the laser through the cooling channels. Provided the damage threshold ratings of the product are not exceeded by subjecting the laser to higher power levels for the incoming beam size, the device will absorb over 99% of the beam for years of use.

Understanding Laser System Behavior

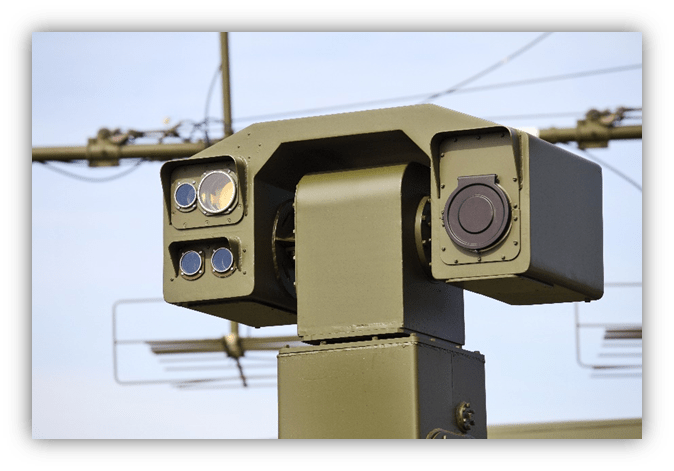

It is true that the success of these laser systems is highly dependent on how well the source laser performs within the system that they are integrated into. Currently, fiber lasers are primarily used in directed energy systems due to their inherent high quality and stability. However, several additional factors must be taken into consideration when designing these systems. Even though the laser source may be stable, the components that are part of the laser system are susceptible to degradation and failure because they are made of physical matter. In addition, the environment in which these laser systems are deployed can be harsh, affecting long-term performance. Beam delivery components, protective housings, and beam shaping optics, can all degrade over time, from normal use or from laser thermal effects. Knowing how these variables affect the overall system’s performance is crucial to its success.

There are several external environmental factors that can affect the system’s ability to neutralize targets. Only the correct amount of power with an accurately positioned beam will be effective in protecting the warfighter soldiers and sailors. Measuring and compensating for changes in laser power and beam position on the target are critical to understanding how to compensate for these losses due to environmental factors. One of the most critical variables is laser power density.

Laser Power Density

Whether you have a laser pointer operating at a few milliwatts, a laser being used for micro welding pulsing at a few Joules of energy per pulse, or a laser being used to disable drones with 10’s or even 100’s of kilowatts of continuous-wave power, the performance of that laser can be characterized by its Power Density (expressed as Watts per square centimeter – W/cm2).

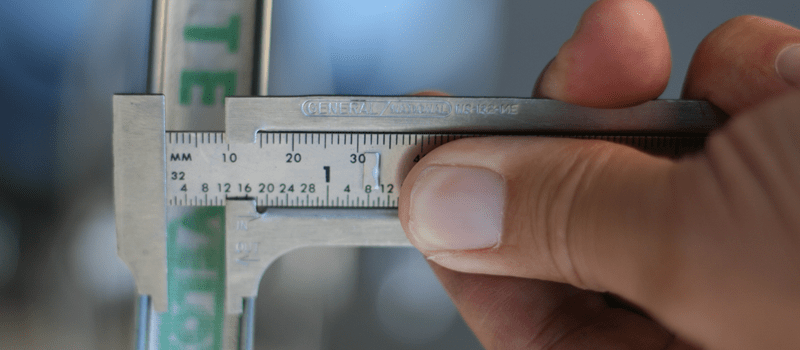

Power Density is defined as the amount of laser light (expressed in Watts for average or continuous-wave power) with respect to the beam size at which the laser is doing its work (expressed in a unit of area such as cm2), commonly known as a “spot size.” Too high a Power Density, due to a relatively higher laser power or relatively smaller spot size, will usually cause the laser to overwork or uncontrollably damage objects in its beam path that aren’t meant to be damaged. Conversely, too low a Power Density, due to a relatively low laser power level or a relatively larger spot size, will cause the laser to not do any work at all. Understanding the laser’s Power Density as it relates to the material being processed is vital to knowing how the overall system will perform.

The top of the Power Density equation (W/cm2) represents the amount of laser light being applied. This is achieved by measuring the laser’s average or continuous-wave power (or pulse energy for pulsed lasers). For Directed Energy lasers, this means 10’s or even the 100’s of kilowatts of power. While you may think that this is difficult to determine, there are devices that will measure laser powers that high. Conventional water-cooled thermopile sensors can measure from 1kW to 30kW of laser power with ±3% NIST-traceable accuracy. In addition, the 150K-W power measurement system mentioned earlier uses calorimeter measurements of differences in water temperature to measure laser average or continuous-wave power with ±5% NIST-traceable accuracy from 10kW to 150kW and beam sizes up to 200mm in diameter.

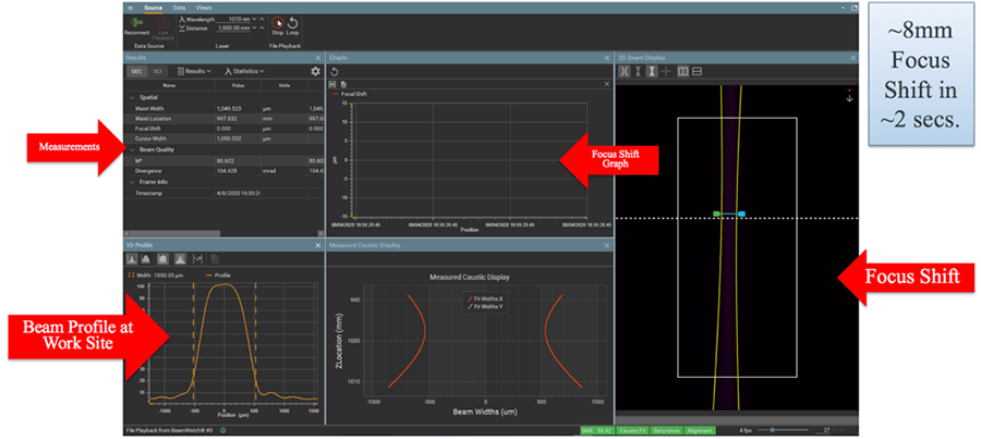

The bottom of the Power Density equation is a measurement of the laser’s beam profile. Beam Profiling is a collection of laser characteristics that correlate to the laser’s quality and usually consist of the size and shape of the laser beam, as well as the spatial or energy distribution across the beam. The quality of the laser can also be measured by its caustic measurements such as Rayleigh Length, M2, Beam Parameter Product (BPP), K value, among others, which are an indication of the laser’s ability to focus.

When a laser source is developed, the manufacturer includes one or more of these ratings in the product specifications to illustrate the quality of the laser being purchased. For example, an M2 rating for a single mode Gaussian laser with a value of 1 would indicate the highest-quality laser possible.

Conclusion

The days are quickly coming when military personnel will no longer be put in harm’s way to defend our country. High-powered Directed Energy laser systems have proven to be an efficient and effective way to neutralize threats. But changes always occur within a laser system, whether because of multi-kilowatt laser thermal effects or the impact of the surrounding environment.

Understanding how these changes affect the overall system performance can only be achieved through measurement of the system’s performance. Tools are now available to perform these measurements and, as a result, improve these system designs. Our fighting men and women deserve the best weapons we can give them.

For more information, see https://www.ophiropt.com

Leave a Reply

Your email address will not be published. Required fields are marked *