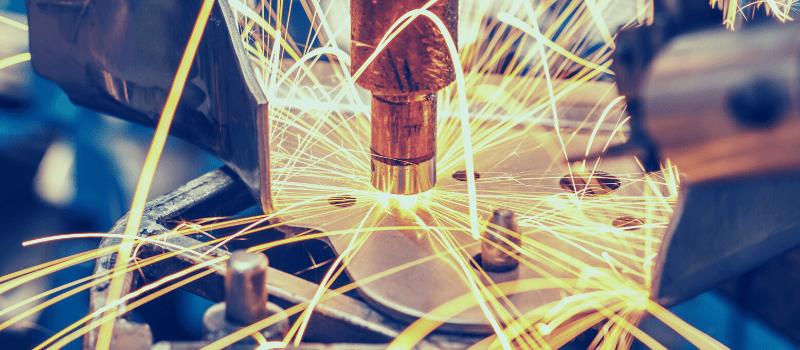

High pressure vessels (over 100 PSI) have high quality standards for their structural integrity, for obvious reasons. Weld points can often pose a critical failure, so these especially must be tested to withstand the high pressure of gas that the container will be used for.

Remote laser welding stations typically use multimode, multi-kilowatt fiber lasers with X/Y scanning mirrors. The work piece is conveyed either linearly or on a circular rotational stage.

Lasers are complex machines with many parts that can degrade over time. A setup that was perfect last year may not provide the same results now. The cover glass accumulates dust and debris which can change the focus spot size, and simple wear and tear to optical parts can decrease the power density of the laser. In either case, the result is the same: poor weld penetration, leading to low-quality pressure vessels that often must be scrapped.

We recently had a customer in this application that was spending time and money testing welds using sacrificial sectioning of the welds to ensure the welds could stand the necessary pressure. This is both time consuming and wasteful, but they had no choice. The alternative would be to risk shipping parts that would not perform under high pressure.

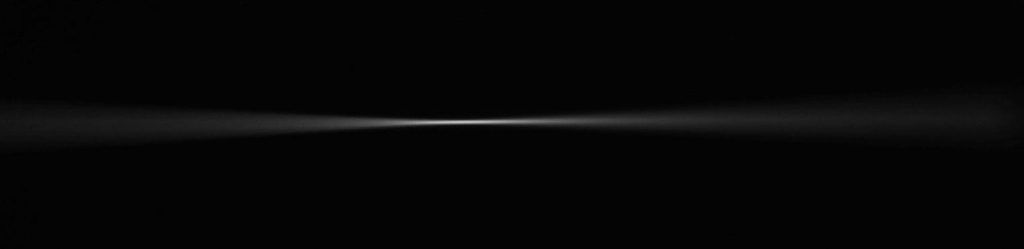

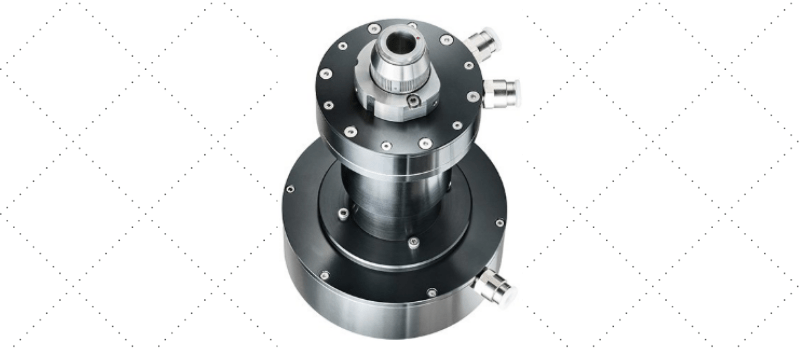

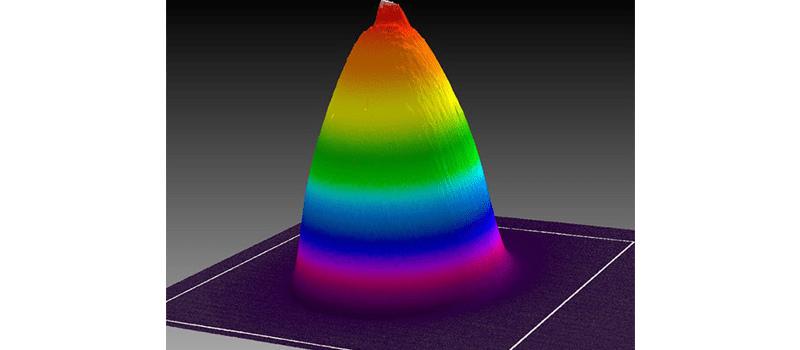

Recently, their lead welding engineer found another way. He started using Ophir’s BeamWatch non-contact beam profiling system and 5kW water-cooled power sensor to monitor the laser properties. BeamWatch provides an image of the laser beam as it propagates through focus. It uses atmospheric scattering (Rayleigh scatter) of the laser light to obtain an image of the beam along its propagation axis.

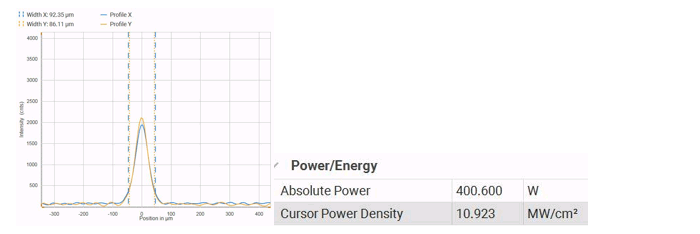

Together with the advanced BeamWatch software, this allows our customer to measure the spot size of the laser anywhere along the beam path throughout the focused region of the beam. Combining this with information from the 5kW power sensor allowed them to further determine the laser power density at any spot along the beam path. Most importantly, it showed them the information critical to the performance of their laser welder: power density at the work surface.

With this new system in place, welding operators can schedule system maintenance when the parameters start to show signs of degradation and avoid unnecessary shut downs. They can also use the system to make sure the laser is focused at the work surface for each weld.

The weld cells are now routinely monitored to assure each is operating at the correct parameters. Measurement data from each cell is logged and monitored for statistically significant changes. The laser performance parameters are now logged for each product build.

Finally, they can use easy, non-invasive methods to monitor their welding process and continue to provide only the highest quality parts.

Leave a Reply

Your email address will not be published. Required fields are marked *