A new measurement procedure allows for the fast and contact-free measurement of the focused laser beam. At the same time, modern measuring devices have Profinet interfaces and allow the processes to be documented. These are enormous advantages, especially in times of just-in-time production.

The challenge – everything has to fit perfectly

Automated laser welding is a big topic in modern production and more and more new applications are being developed. Be it pairing materials that were previously considered to be non-weldable, complex contours or extremely stressed components, a good deal of specialist knowledge is always required; after all, everything has to fit perfectly, from material properties to clamping technology and laser beam. This also applies to the measurement technology used for quality assurance.

The weld seam itself can only be checked by random samples where material is destroyed or by time and cost-intensive ultrasound tests. If weaknesses are actually found during such an inspection, the bad parts must be sorted out after all costs of the value chain have already been incurred.

It is significantly cheaper to proactively ensure the consistent quality of weld seams. The joining gap caused by the clamping process and the position of the weld seam are often checked by cameras or laser triangulation sensors, but exact compliance with the defined specifications of the focused laser beam itself is a challenge at high power densities.

All-in-One Sensors

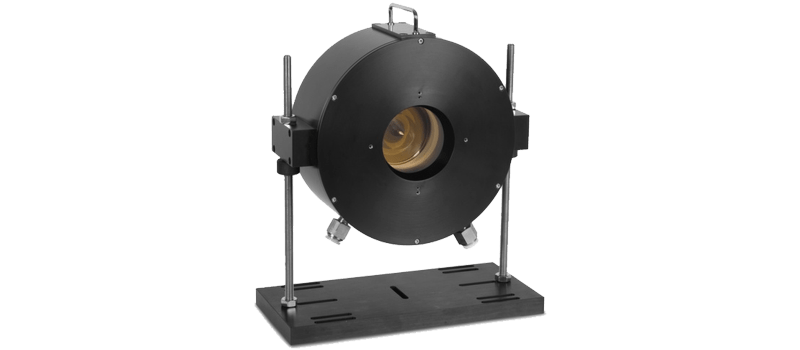

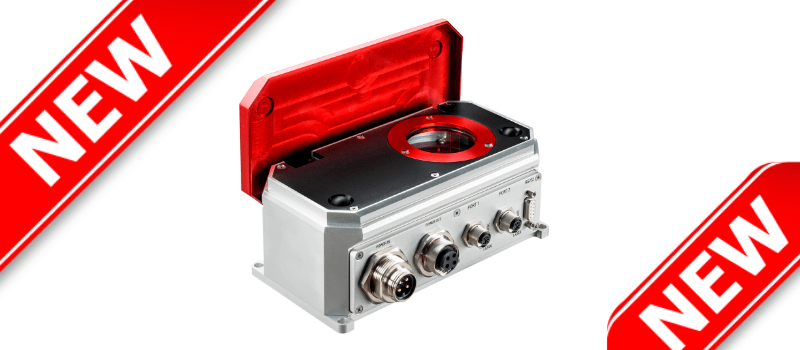

MKS Instruments developed the robust and compact performance measuring device Ophir Helios to be specifically used in automated production, which, for less critical applications, provides reliable clues as to whether the basic parameters for the precise implementation of weld seams can be observed.

The measuring device measures the power and energy of industrial diodes, fiber or Nd:YAG lasers during a short irradiation time between 0.1 and 10s and uses this to calculate the total power up to a maximum of 12 kW or total energy up to 10 kJ. If the measured values lie outside the process window defined by the user, intervention is required.

For further reading please click here

Leave a Reply

Your email address will not be published. Required fields are marked *