The Evolution of the Metalworking Industry: Embracing Additive Manufacturing

The metalworking industry is experiencing transformative changes as additive manufacturing methods redefine processes and enable innovative designs. Reichenbacher Hamuel GmbH, globally recognized for its high-quality 5-axis CNC machining centers, has embraced this potential. By developing large-format industrial laser powder bed fusion (LPBF) machines equipped with multiple laser beams, the company has positioned itself at the forefront of this evolution.

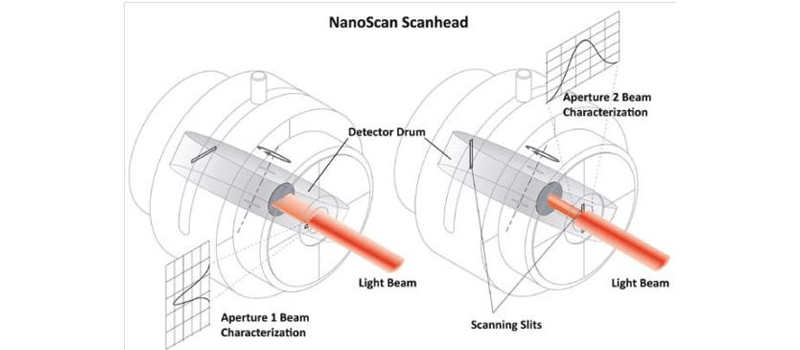

A crucial element of their success is the integration of advanced measuring technology. For research, development, quality assurance, and maintenance, Reichenbacher relies on the compact Ophir BeamPeek high-power laser beam analysis and power measurement system from MKS Instruments. Since Reichenbacher customizes its large-format additive manufacturing systems to meet individual customer requirements, each setup involves optimizing various laser sources, optics, and materials from the ground up. Here, the user-friendly design and versatile capabilities of the BeamPeek measurement solution prove invaluable. In particular, Reichenbacher’s industrial scale AM systems, which can deploy up to four fiber lasers to build a single part, need to exactly comply with specifications to ensure consistent quality. This precision would not be possible without robust measurement and calibration technologies.

As the metalworking industry continues to adapt to new technologies, companies like Reichenbacher demonstrate how innovation can drive progress and efficiency.

For more details on how Reichenbacher uses the BeamPeek system to measure laser beam performance and the advantages of precise laser measurement, please read our case study.

Leave a Reply

Your email address will not be published. Required fields are marked *