What do you enjoy doing outside of work?

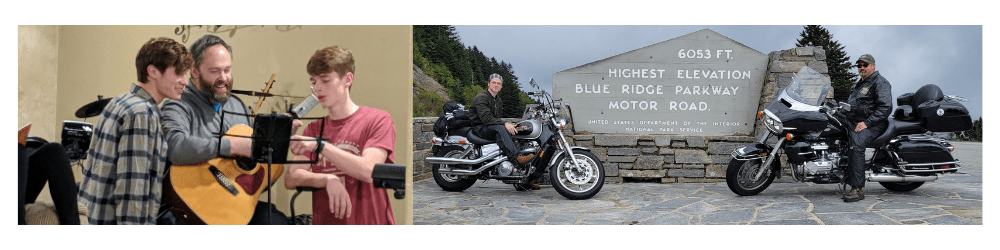

We have a family that’s larger than most families with six kids, so most of my activities outside of work involve them. We enjoy camping throughout the year, along with just being outside in nature. My two older boys and I ride motorcycles and we like to take as many rides as possible throughout the year. We’re also a musical family. I’ve enjoyed playing musical instruments most of my life, from the trombone in the marching band, bass guitar in jazz band, along with playing hair metal bass guitar in a garage band in high school, to now sitting around the campfire strumming folk and country music songs on my acoustic 12-string and bass guitars.

You have had a very broad career history. How did you go from being a nuclear-trained submariner to becoming a business development manager and field sales engineer?

There are many things that I learned while serving in the US Navy that I’ve carried over into my current career. For instance, when operating an active nuclear power plant several feet underwater (with nowhere to run to if things go wrong), I learned that even while being in a military environment where an operator must follow orders, the operator must understand the orders being given and how that will affect the power plant. The same can be true with today’s tasks and professional relationships.

As proud as I was to serve our country, I knew that staying in nuclear power when separating from the Navy was not something that I wanted to do. I was fortunate to find a position with a small laser engraving job shop, which is where I got my start in lasers. Operating and developing applications for laser markers provided me with a strong understanding of industrial lasers used for material processing. It also gave me exposure to working directly with customers on solution development and representing our company at industry trade shows which came to be valuable at my current position with Ophir.

What’s the best aspect of the work you do?

I love working with customers, especially in the Midwest United States. Listening to them discuss their roles and their laser issues, and then working with them to develop solutions for them is always rewarding to me. And, if we do not have a current solution for them, it gives us at Ophir opportunities to listen to real-world problems that our customers have which allows us to progress as a company which solves laser problems.

How does Ophir add value to industrial laser material processing for customers?

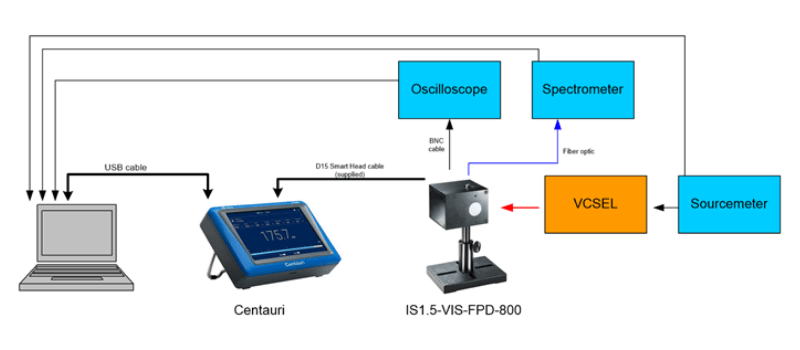

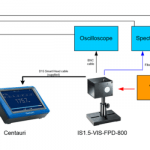

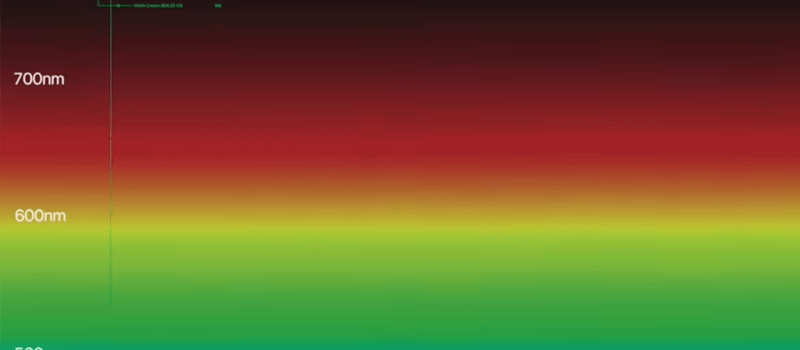

Living in the Midwest U.S. allows me to work with several industrial manufacturing companies, from automotive component to medical device component manufacturing. When a laser is put into production, it will tend to drift from its peak efficiency. For a system to perform as efficiently as it was designed, those responsible for operating and maintaining the system must understand how that system operates and behaves. Since the laser is essentially an invisible tool, it adds a layer of complexity when it comes to evaluating the process. Ophir provides the solutions that measure key laser performance indicators and for a more clear understanding of the laser performance to keep system efficiency high and consistent.

In Business Development, what are the most common challenges you see?

Having taken on the first formal Business Development role for our Automotive customers in The Americas, there were many challenges to start off with. Laying a working strategy to find key customers, key locations, key contacts, and key laser applications, and mapping out where we could make the most difference was how we started our approach. In this ever-evolving sub-market, this has continued to be challenging. Most industrial customers today are facing economic challenges with supply chain disruptions and climbing inflation in the post-COVID era, which adds to the current challenges working with Automotive and other industrial customers.

The challenges haven’t all be external to Ophir. Historically, Ophir and Spiricon have done very well in research and academic markets, and as a result, most of our products are suitable for laser measurements in those clean work environments. Ophir has only relatively recently started to develop products for operation in relatively dirty industrial processing environments. These developments have been a welcomed change to Ophir’s product line and it is exciting to see how this will allow us to compete in these industrial marketplaces in the future.

Leave a Reply

Your email address will not be published. Required fields are marked *