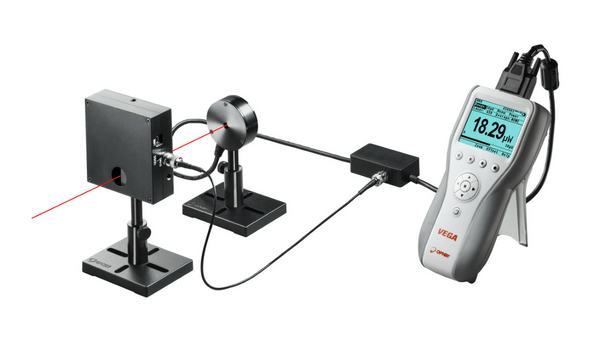

When it comes to laser measurement systems, accuracy is super important. A world-leader like Ophir uses strict processes to ensure measurement accuracy and analyze calibration errors – let’s look at Ophir’s article and see how they’re making sure their laser power and energy meters meet specifications.

The total accuracy of measurement is based on many different factors – such as wavelength, sensor linearity, uniformity of readings over the surface, pulse rate, display unit calibration uncertainty, damage done to the absorber surface, and electromagnetic interference. The article describes all of these factors, and how they are handled when it comes to Ophir sensors – read the article in full to find out more.

That being said, the article primarily discusses two factors – firstly – the calibration uncertainty of the measuring sensor at the power level, energy level, and wavelength at which it was calibrated, and secondly – the energy calibration uncertainty – this is the extra error due to the extra calibration step needed to calibrate energy.

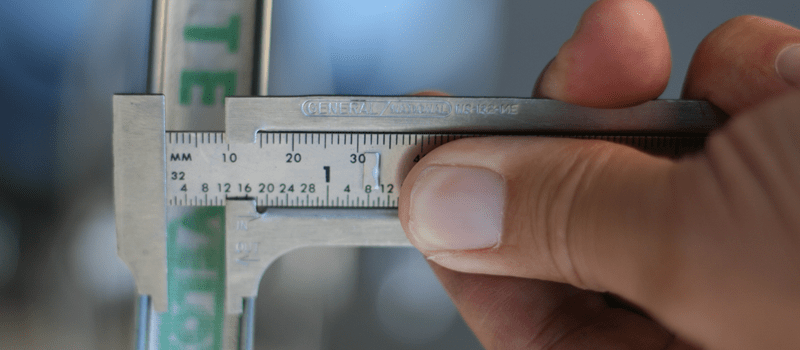

In 95% of cases, Ophir’s system errors are promised to not exceed the stated error. For example, if the stated error is plus minus 3 percent, then in 95% of cases, it will not exceed 3%, and in 99% of cases, it will not exceed 4%.

Ophir goes to great lengths to ensure sensors are calibrated to meet strict requirements. The possible errors are analyzed using advanced statistical techniques, resulting in specifications with great accuracy. This is done for all types of sensors, and the article outlines the exact calculations made, as well as the resulting expected error, for each type of Ophir measurement device.

If you’re interested in knowing all of the hard work that goes into ensuring Ophir’s high quality laser measurement devices have accurate specifications and minimal total error, be sure to check out the article.

Leave a Reply

Your email address will not be published. Required fields are marked *